New energy automobile battery shell polishing device for intelligent manufacturing

A technology for new energy vehicles and battery casings, applied in grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of manpower consumption, manpower and time consumption, energy consumption, etc., to reduce manpower and time, reduce Waste of cost and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

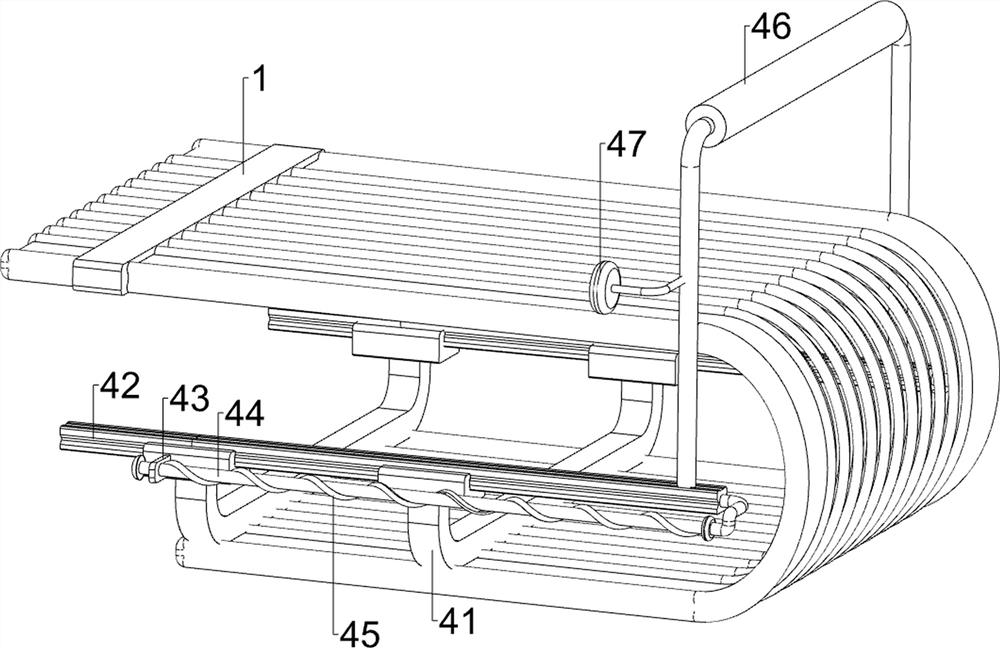

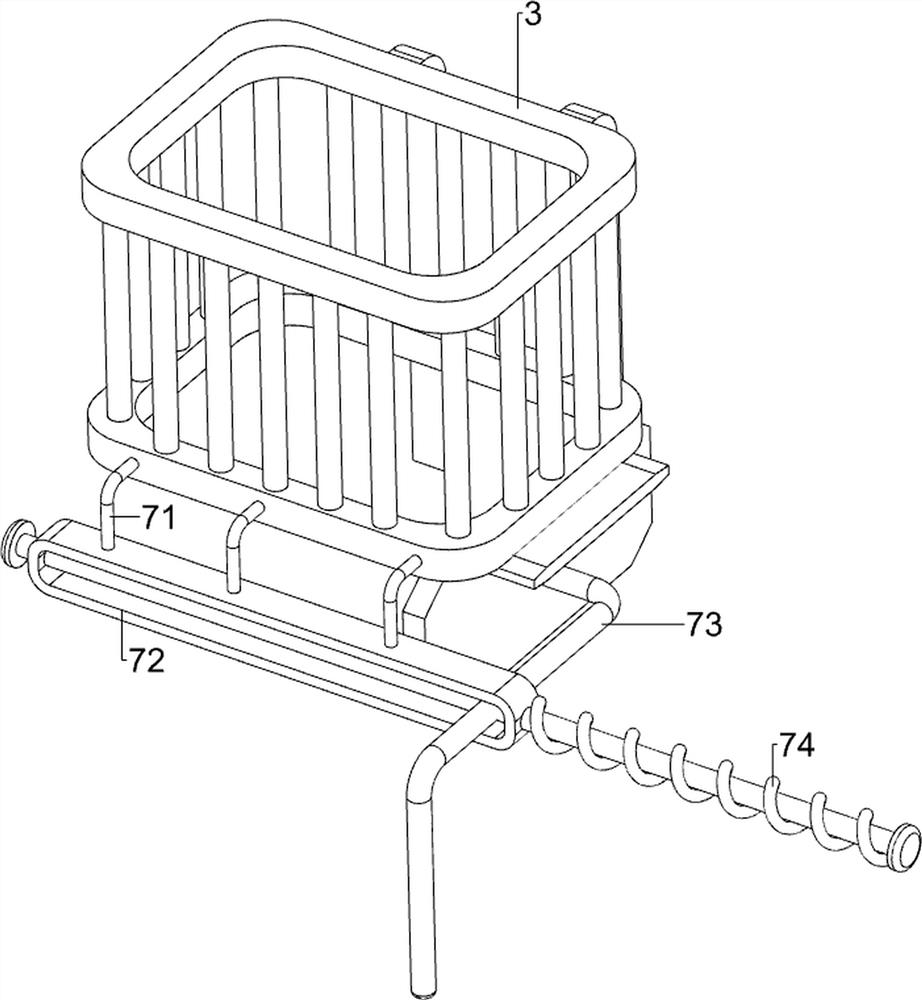

[0059] A new energy vehicle battery shell polishing equipment for intelligent manufacturing, such as figure 1 As shown, the first support frame 1, the second support frame 2, the discharge frame 3, the grinding mechanism 4 and the automation mechanism 5 are included, the first support frame 1 and the second support frame 2 are placed on the ground, and the first support frame 1 and the inner side of the second support frame 2 are interlaced, the second support frame 2 is provided with a discharge frame 3 on the rear side, the first support frame 1 is provided with a grinding mechanism 4, and the first support frame 1 and the grinding mechanism 4 are provided with There are automated mechanisms5.

[0060] When people need to polish the car battery casing, people put the car battery in the discharge frame 3, and now the car battery is on the second support frame 2, and people open the automatic mechanism 5, and then people manually push the car battery to the left side movement, ...

Embodiment 2

[0062] On the basis of Example 1, such as figure 2 As shown, the grinding mechanism 4 includes a third support slideway assembly 41, a slide rail 42, a first fixed plate 43, a first slide bar 44, a first spring 45, a polisher 46 and a first round bar 47, the first The left and right sides of support frame 1 are all provided with the 3rd support slideway assembly 41, all sliding type is provided with slide rail 42 between two 3rd support slideway assemblies 41 front and back sides, the 3rd support slideway assembly on the left side 41 front and back two parts are all provided with first fixed plate 43, and two slide rails 42 right sides are all provided with first sliding rod 44, and first sliding rod 44 is connected with the first fixed plate 43 slidingly, two first sliding rods 44 is equipped with the first spring 45, the two ends of the first spring 45 are connected with the first fixed plate 43 and the first slide bar 44 respectively, a polisher 46 is arranged between the ...

Embodiment 3

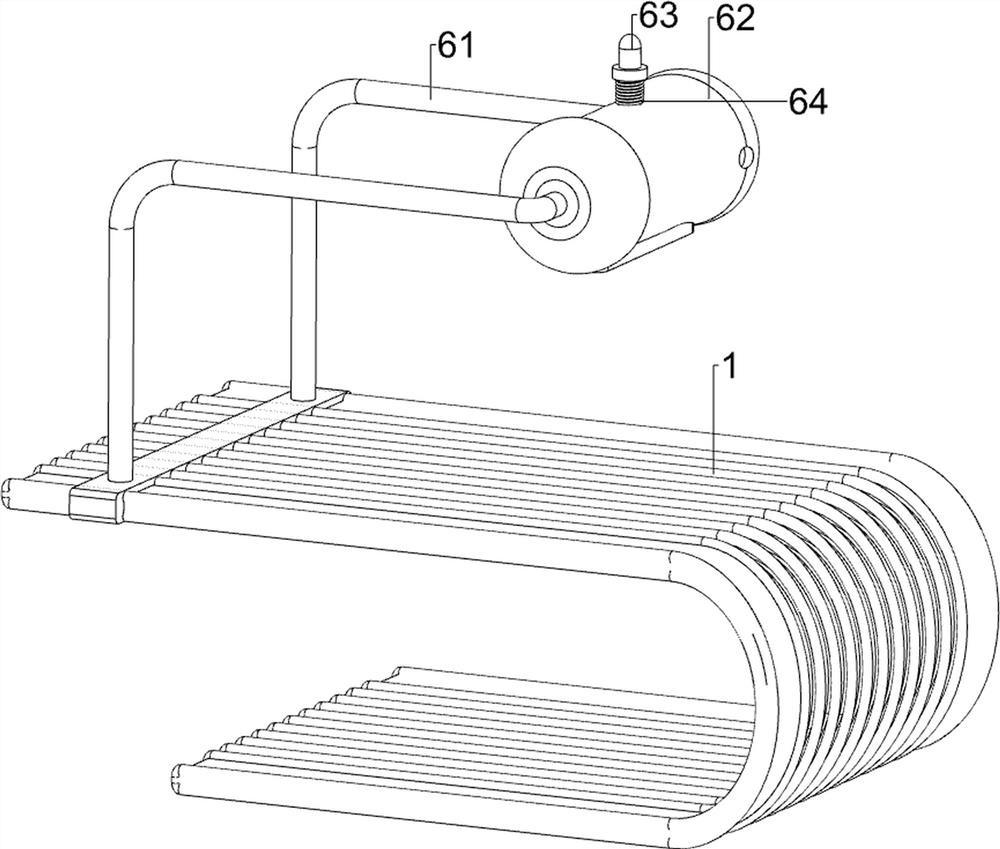

[0065] On the basis of Example 2, such as figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 As shown, the automation mechanism 5 includes a fourth support assembly 51, a cylinder 52 and a power push rod 53. The first support frame 1 is provided with a fourth support assembly 51, and the fourth support assembly 51 is provided with a cylinder 52. The telescoping rod is connected with a power push rod 53, and the power push rod 53 is connected with the two slide rails 42.

[0066] When the car battery moves to the first support frame 1, people will open the cylinder 52, so that the telescopic rod of the cylinder 52 will move the power push rod 53 to the left, and then drive the slide rail 42 to move to the left, so that the polisher 46 moves to the left. Moving to the left, when the telescopic rod of the cylinder 52 moves the power push rod 53 to the right, the slide rail 42 is moved to the right, so that the polisher 46 polishes the car battery shell bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com