Mold hot nozzle heat insulation device and injection mold

A technology of heat insulation device and injection mold, applied in the field of mold, can solve the problems of thermal expansion of template, affecting product quality and qualification rate, affecting mold accuracy, etc., to improve precision, reduce cracking and demoulding difficulties, and improve service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

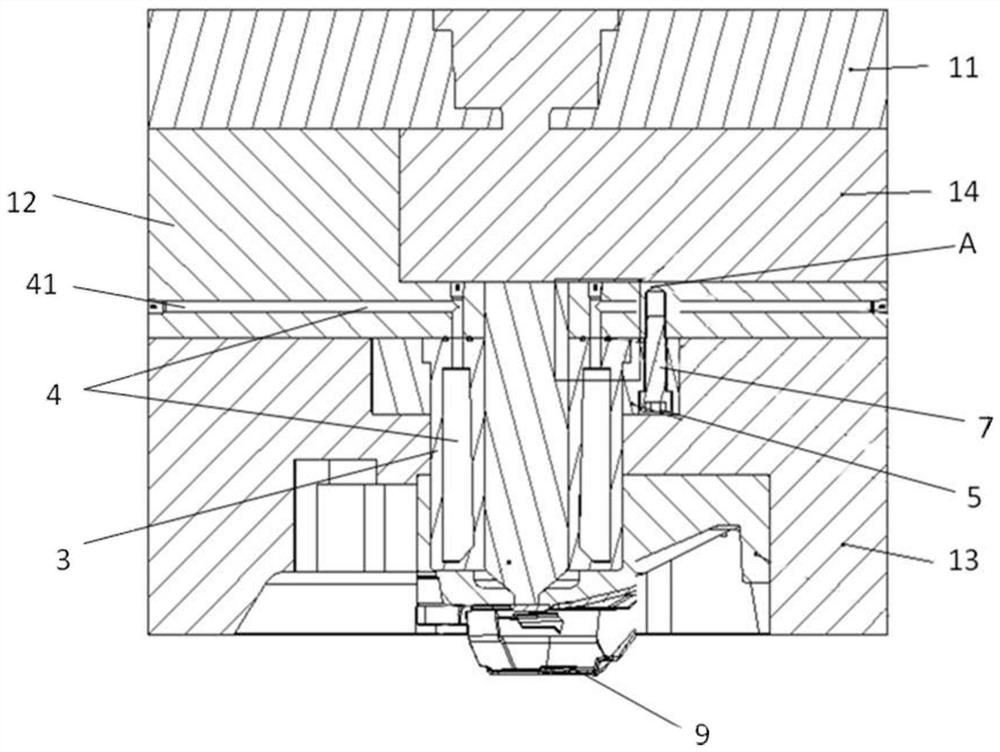

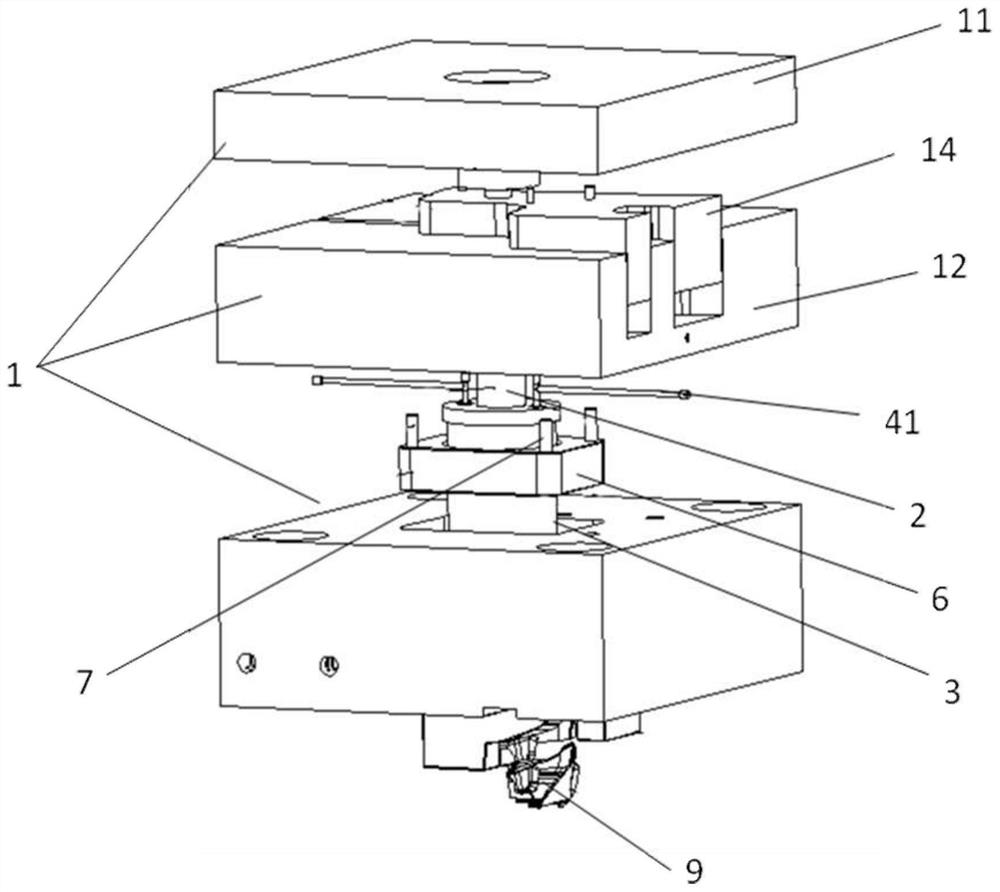

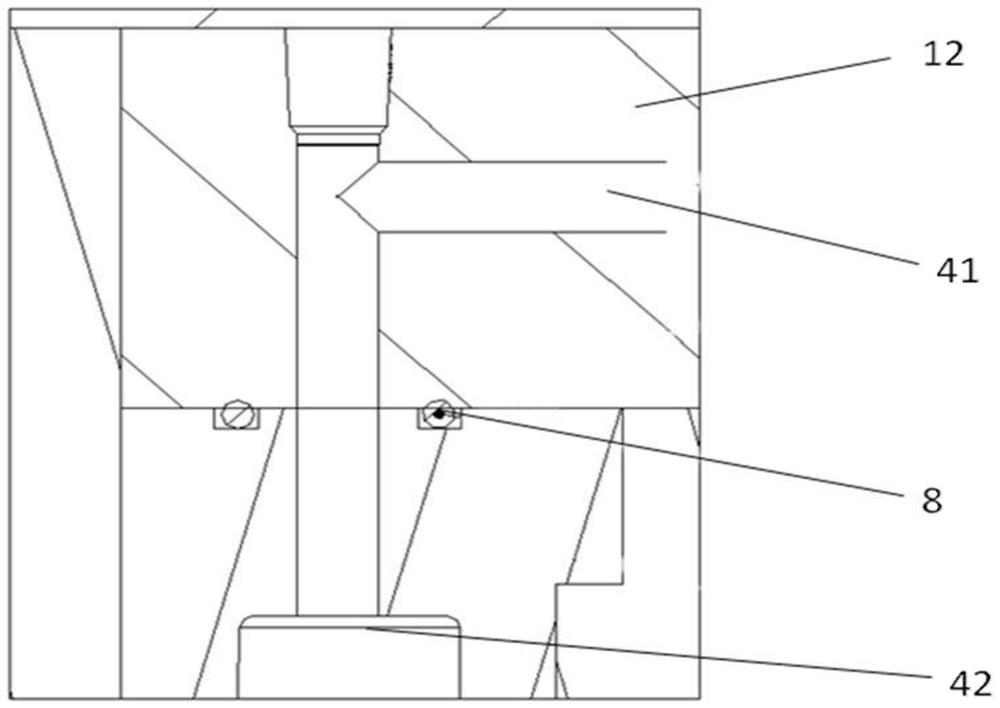

[0027] The invention provides a heat insulation device comprising a mold hot nozzle, see Figure 1 to Figure 4 , including a heat insulation sleeve 3 and a circulating cooling system 4, the heat insulation sleeve 3 is fixed in the mold 1, and the mold 1 includes a cylinder plate 11, a splitter plate 12 and a master template 13 arranged in sequence from top to bottom, the said A hot runner system 14 is provided on the distributor plate 12 , and the hot runner system 14 is used for heating the nozzle 2 . The height of the heat insulation cover 3 is lower than the height of the hot nozzle 2 to increase the heat exchange area between the cooling water and the hot nozzle 2. At the same time, the heat insulation cover 3 does not hinder the normal operation of the hot nozzle 2. The thermal sleeve 3 is sleeved on the outer periphery of the hot nozzle 2 . Wherein, the circulating cooling system 4 includes a flow guide pipe 41 and a cooling pipe 42, the cooling pipe 42 is arranged in t...

Embodiment 2

[0032] The present invention also provides an injection mold 1, see figure 1 , figure 2 , the injection mold includes the mold hot nozzle thermal insulation device described in Embodiment 1. It should be noted that the hot nozzle 2 is a runner structure with heating wires arranged inside. Specifically, the inside of the hot nozzle 2 is covered with heating wires. When the hot runner system 14 heats the hot nozzle 2, the heat The nozzle 2 can heat up quickly, and the heated nozzle 2 can melt the plastic particles, so that the melted plastic liquid can flow into the core of the master mold through the bottom of the nozzle 2, and finally the product 9 is obtained.

[0033] When the temperature of the hot nozzle 2 is too high, the heat of the hot nozzle 2 is easily transferred to the mold 1, causing thermal expansion of the mold 1, which in turn causes the thermal expansion of the mold 1 to crack, and the resulting product 9 is also prone to difficulties in demoulding. Therefor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com