Industrial sewage staged treatment device

A technology for graded treatment and industrial sewage, applied in water/sewage multi-stage treatment, water/sewage treatment, water/sewage treatment equipment, etc., can solve problems such as large differences in properties, large accumulation, toxicity, etc., and achieve good treatment , increase work efficiency, and improve the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

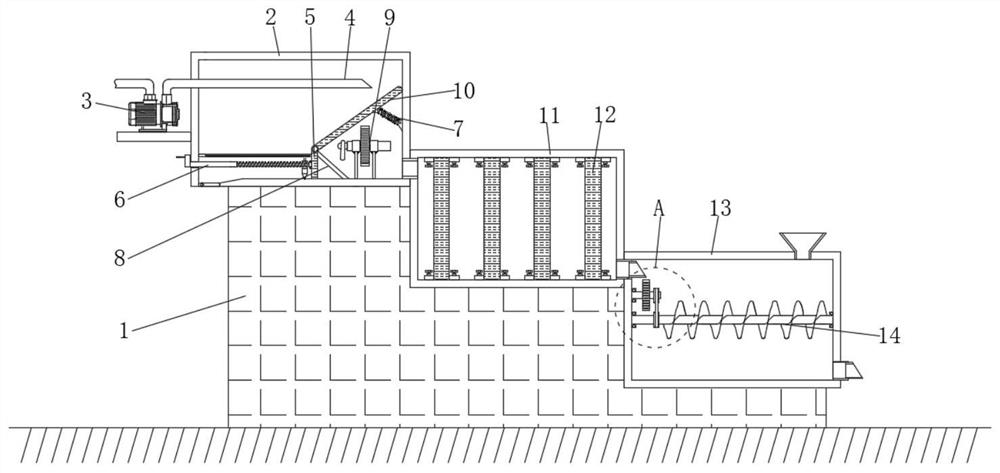

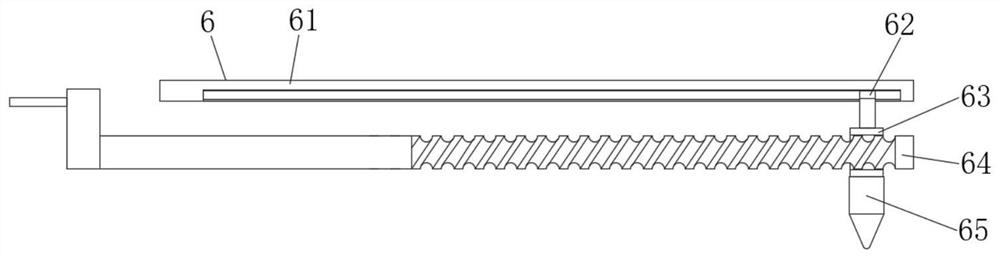

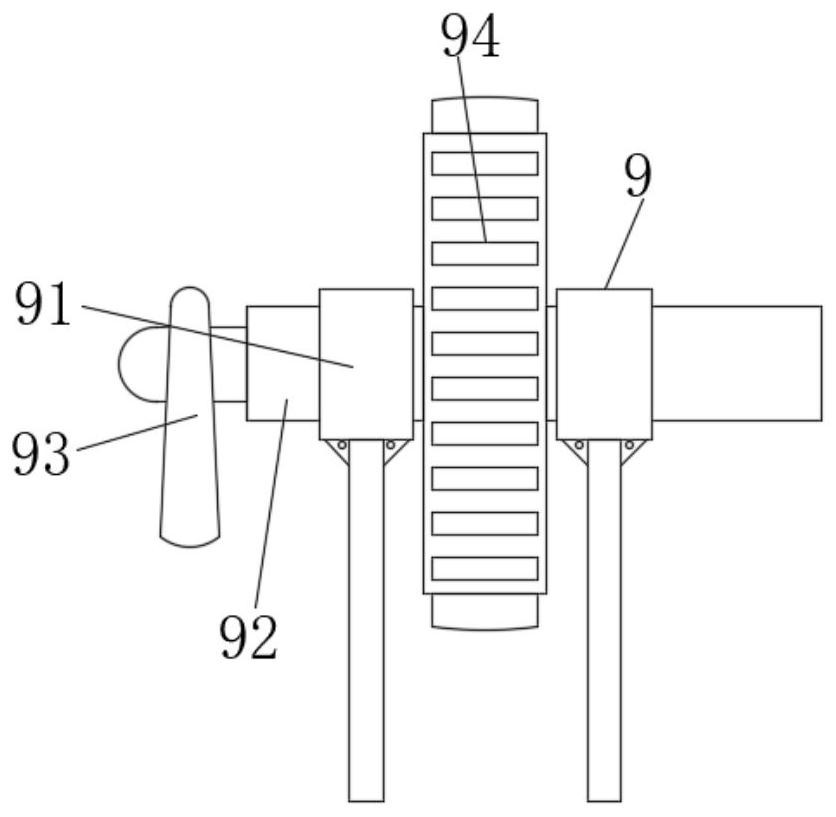

[0043] see Figure 1-5, an industrial sewage classification treatment device, including a support base 1 and a water pump 3, the top of the support base 1 is provided with a first water tank 2, and the left side of the first water tank 2 is provided with a water pump 3, and the water outlet of the water pump 3 is provided with The water pipe 4, the inner bottom of the first water tank 2 is provided with a first filter plate 5, and the left side of the first filter plate 5 is connected with a desilting mechanism 6, the desilting mechanism 6 includes a fixed rod 61, and the fixed rod 61 is arranged on In the inside of the first water tank 2, a slide block 62 is inserted inside the right side of the fixed rod 61, and the bottom end of the slide block 62 is provided with a sliding sleeve 63, and the bottom end of the sliding sleeve 63 is provided with a scraper 65, and the bottom end of the sliding sleeve 63 is provided with a scraper 65. A screw 64 is inserted inside, and the top...

Embodiment 2

[0051] An industrial sewage classification treatment device, comprising a support base 1 and a water pump 3, the top of the support base 1 is provided with a first water tank 2, and the left side of the first water tank 2 is provided with a water pump 3, and the water outlet of the water pump 3 is provided with a water pipe 4. The inner bottom of the first water tank 2 is provided with a first filter plate 5, and the left side of the first filter plate 5 is connected with a desilting mechanism 6. The desilting mechanism 6 includes a fixed rod 61, and the fixed rod 61 is set on the second Inside of a water tank 2, a slide block 62 is inserted inside the right side of the fixed rod 61, and the bottom end of the slide block 62 is provided with a slide sleeve 63, and the bottom end of the slide sleeve 63 is provided with a scraper 65, and the inside of the slide sleeve 63 A screw 64 is inserted, and the top end of the first filter plate 5 is hingedly connected with the second filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com