Composite preparation method of high-density coating

A coating and dense technology, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of substrate material damage, unrealistic, low preparation rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Place the substrate in the reaction chamber and evacuate the reaction chamber to 1×10 -3 Pa;

[0022] (2) Heating the substrate to 700°C and maintaining it;

[0023] (3) Iridium (Ir) coatings were prepared using atomic layer deposition technology, and the two precursors were iridium acetylacetonate (Ir(acac) 3 ) and oxygen (O 2 ), the coating thickness is 0.1 μm;

[0024] (4) Utilize chemical vapor deposition technology to prepare iridium (Ir) coating, the preparation source gas is iridium acetylacetonate (Ir(acac) 3 ), the coating thickness is 2 μm;

[0025] (5) Alternately repeat the above steps (3) and (4), wherein step (3) is repeated 51 times, and step (4) is repeated 50 times.

Embodiment 2

[0027] (1) Place the substrate in the reaction chamber, and evacuate the reaction chamber to 2×10 -3 Pa;

[0028] (2) Heating the substrate to 600°C and maintaining it;

[0029] (3) Using atomic layer deposition technology to prepare hafnium oxide (HfO 2 ) coating, the two precursors are hafnium tert-butoxide (Hf(t-BuO) 4 ) and oxygen (O 2 ), the coating thickness is 0.05μm;

[0030] (4) Preparation of hafnium oxide (HfO 2 ) coating, the preparation source gas is hafnium tert-butoxide (Hf(t-BuO) 4 ) and oxygen (O 2 ), the coating thickness is 2 μm;

[0031] (5) Alternately repeat the above steps (3) and (4), wherein step (3) is repeated 51 times, and step (4) is repeated 50 times.

Embodiment 3

[0033] (1) Place the substrate in the reaction chamber, and evacuate the reaction chamber to 4×10 -3 Pa;

[0034] (2) Heating the substrate to 700°C and maintaining it;

[0035] (3) Iridium (Ir) coatings were prepared using atomic layer deposition technology, and the two precursors were iridium acetylacetonate (Ir(acac) 3 ) and hydrogen (H 2 ), the coating thickness is 0.1 μm;

[0036] (4) Utilize chemical vapor deposition technology to prepare iridium (Ir) coating, the preparation source gas is iridium acetylacetonate (Ir(acac) 3 ), the coating thickness is 2.5 μm;

[0037] (5) Alternately repeat the above steps (3) and (4), wherein step (3) is repeated 41 times, and step (4) is repeated 40 times.

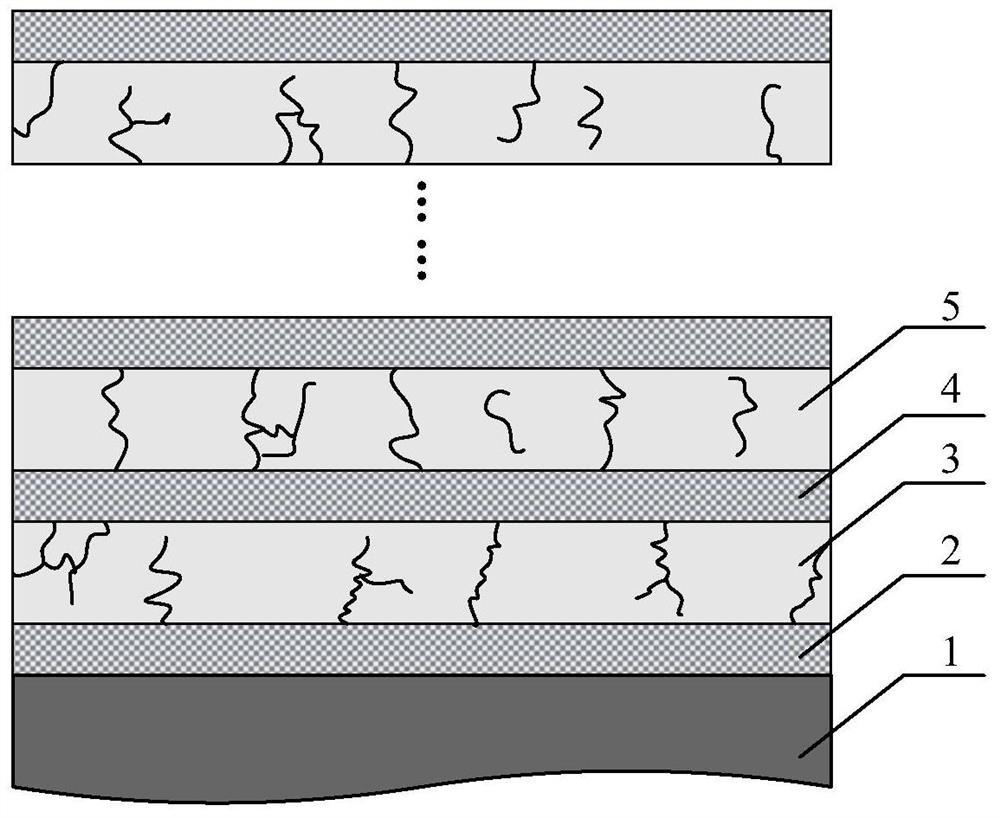

[0038] The present invention combines the two technologies of atomic layer deposition and chemical vapor deposition, and uses the two technologies to alternately prepare the coating, and can utilize the high density of the atomic layer deposition coating to realize the elimin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com