Silicon carbide single crystal growth method

A silicon carbide single and growth method technology, applied in the direction of single crystal growth, single crystal growth, crystal growth, etc., can solve the problem that carbon is not fully utilized, achieve the effect of reducing production cost and increasing nitrogen doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention discloses a method for growing a silicon carbide single crystal, which comprises the following steps:

[0022] Step 1. Perform the first heat treatment on the silicon carbide powder; the conditions for the first heat treatment are: temperature 2030±25° C., pressure 500±50 torr, and treatment time 3±0.25 hours.

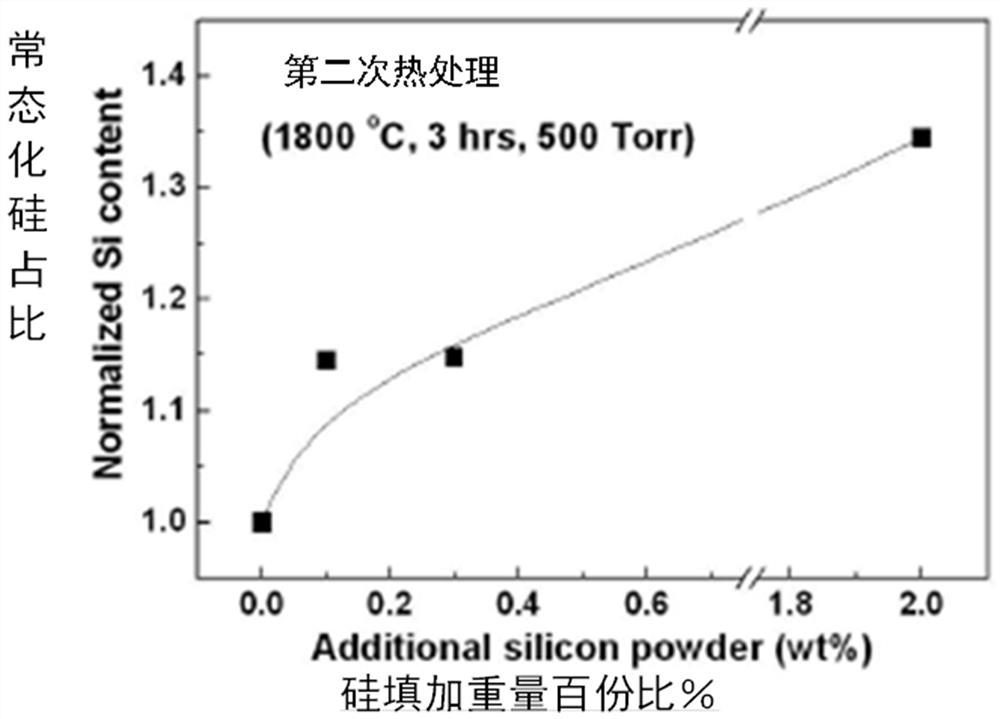

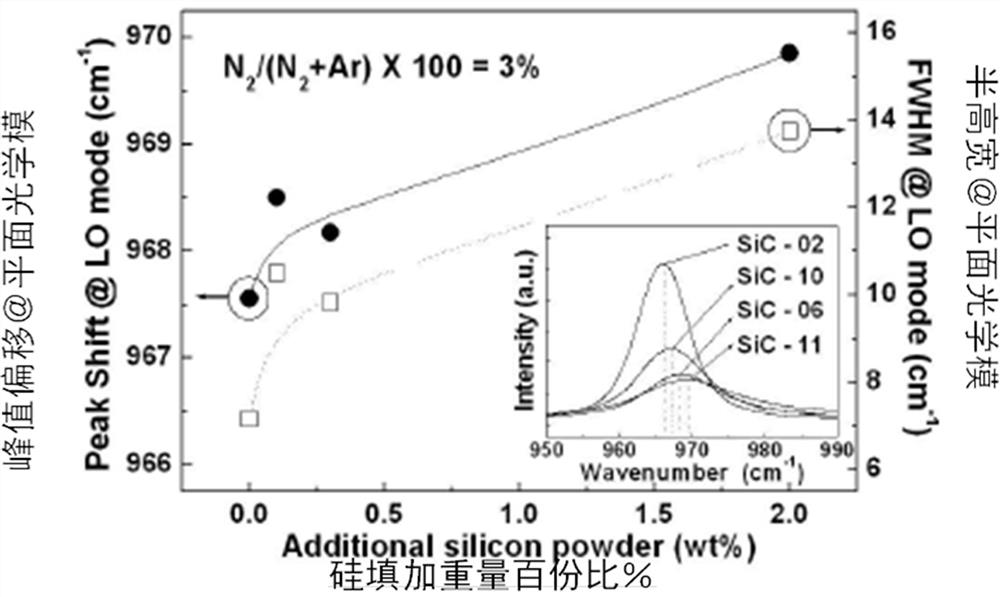

[0023] Step 2, adding 1wt%-2wt% silicon powder to the silicon carbide powder treated in step 1, so as to increase the silicon content in the silicon carbide powder.

[0024] Step 3. The silicon / silicon carbide powder obtained in step 2 is subjected to a second heat treatment to eliminate excess silicon carbide metal. The temperature of the second heat treatment is different from the temperature of the first heat treatment, and the conditions of the heat treatment are: temperature 1800±25°C, pressure 500±50 torr, and treatment time 3±0.25 hours.

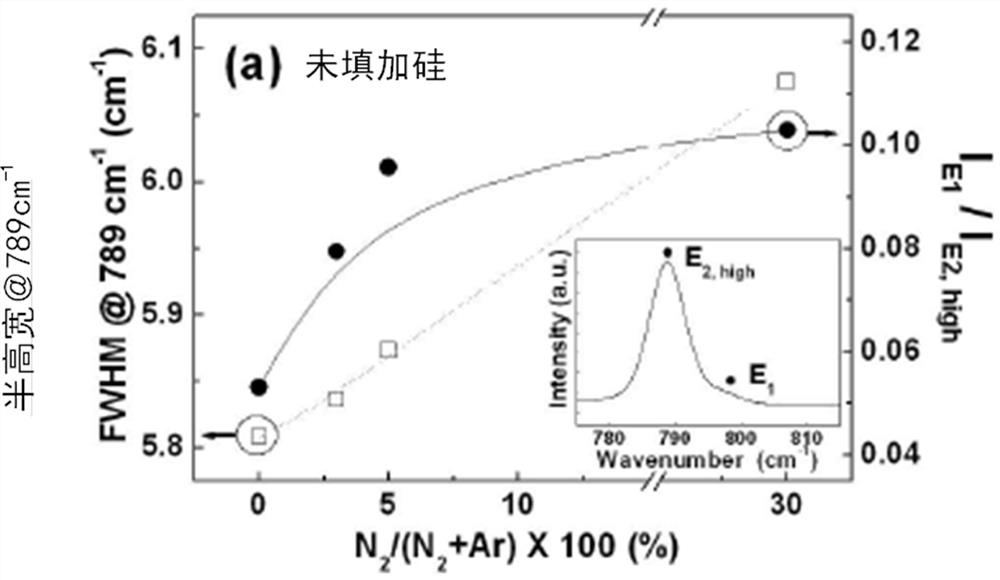

[0025] Step 4. Use the silicon / silicon carbide powder treated in step 3 as the growth source, and use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com