Bridge water surface pile tie beam hoisting device and construction method thereof

A hoisting device and tie-beam technology, applied to bridges, bridge construction, bridge parts, etc., to achieve the effects of reasonable design, low input cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

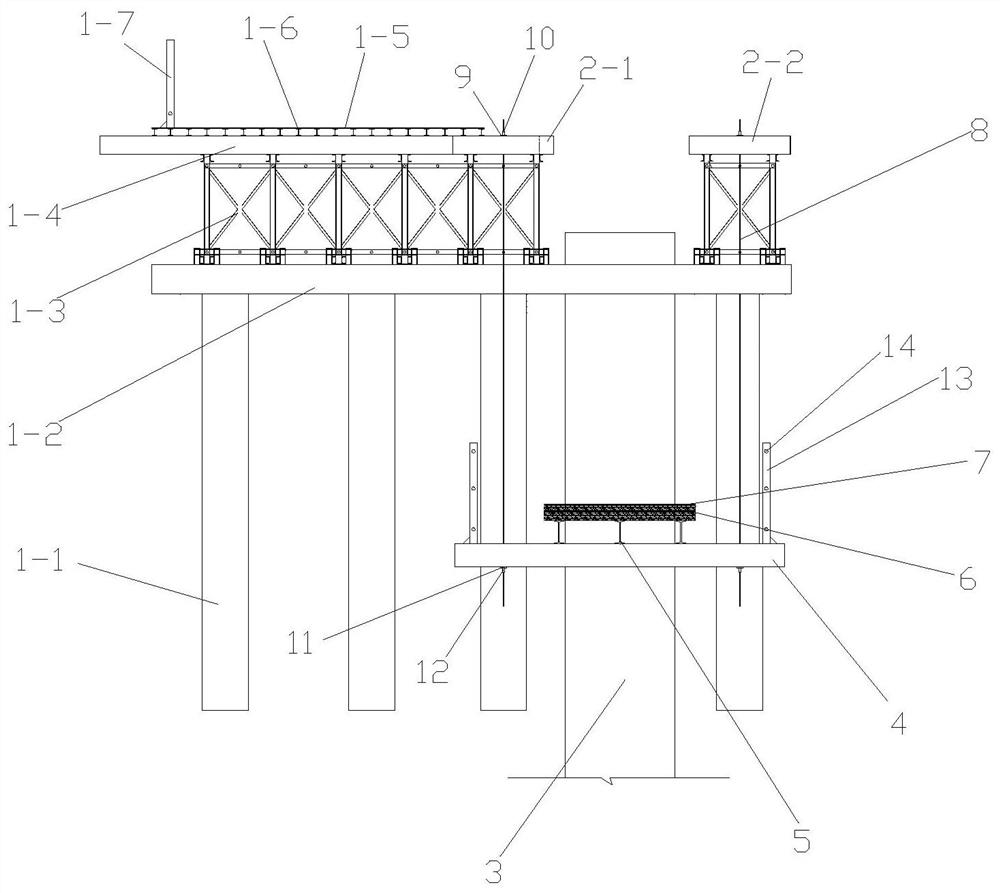

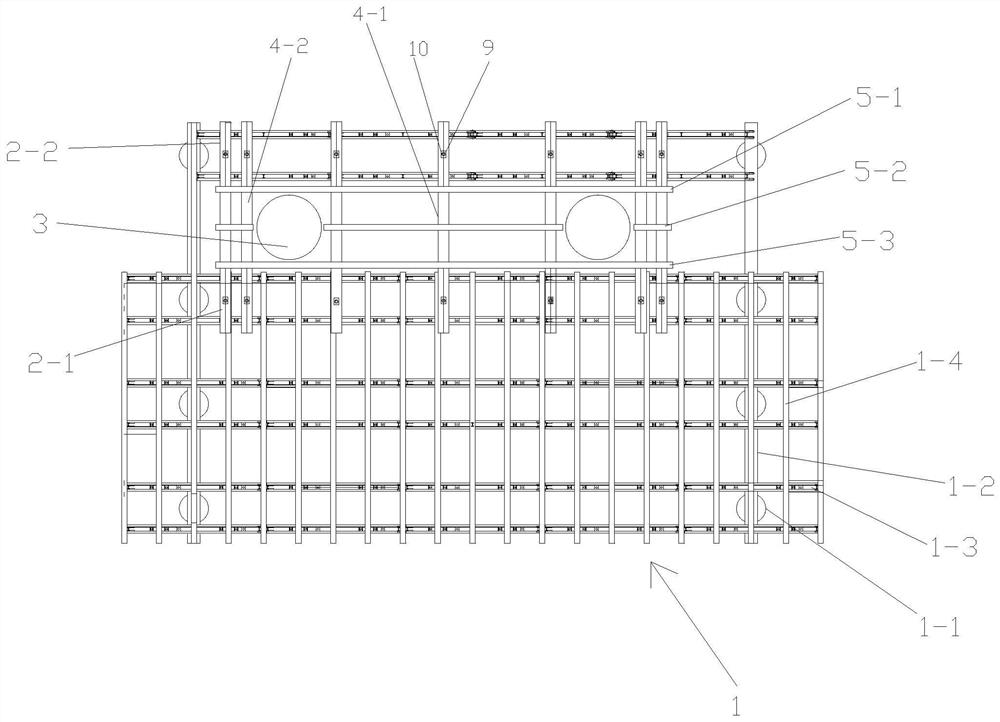

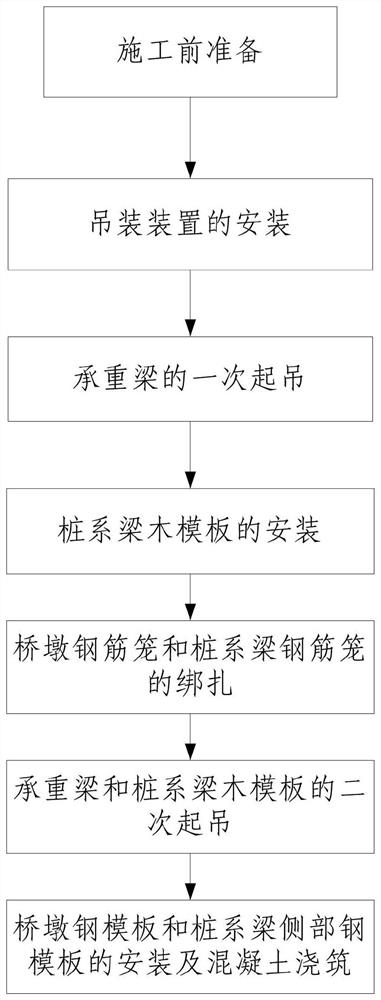

[0074] Such as figure 1 and figure 2 The shown hoisting device for piles and tie beams on the water surface of a bridge includes a lifting point support arranged on the construction work platform 1, a load-bearing mechanism connected with the lifting point support, and a pile mounted on the load-bearing mechanism. Tie beam wood formwork, a hoisting part is arranged between the lifting point support and the load-bearing mechanism;

[0075] The load-bearing mechanism includes a plurality of lower longitudinal beams 4 arranged under the suspension point supports and load-bearing beams 5 arranged on the plurality of lower longitudinal beams 4, and the pile beam wooden formwork includes a Square timber 6 and the bamboo plywood 7 that are arranged on the square timber 6;

[0076] The hoisting parts include a suspender 8 passed between the suspension point support and the lower longitudinal beam 4, an upper adjusting nut 10 sleeved on the suspender 8 and located on the suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com