Double-groove hedging energy dissipation method and spillway thereof

A spillway and energy dissipation technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems of large project investment, waste of stone excavation costs, and difficult construction of high slopes, so as to reduce project investment, The effect of reducing the amount of energy dissipation works and reducing the potential energy of floods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

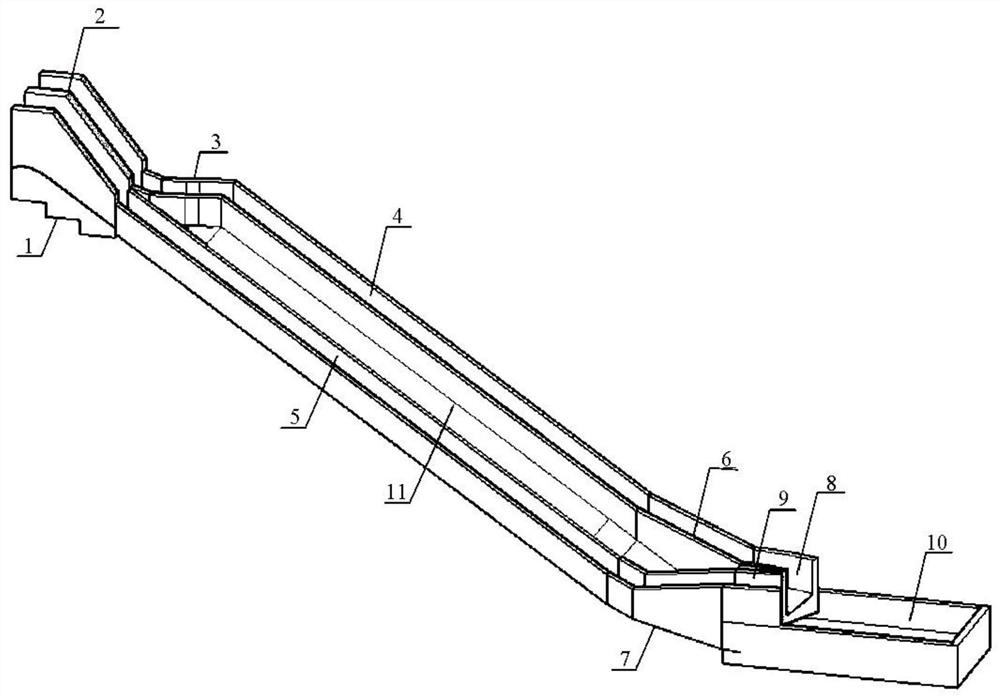

[0018] Such as figure 1 As shown, the double-groove hedging energy dissipation spillway of the present invention mainly includes the following parts: overflow weir 1, gate pier 2, turning gradual change section 1 3, high side discharge chute 4, low side discharge chute 5, turning gradual change section 2 6, Turning transition section 3 7, down discharge port 8, up pick port 9, apron 10, side slope 11 between two-stage chute, etc.

[0019] Spillway overflow weir 1 and gate pier 2 are the main structures of conventional spillways. The key of the present invention is that the high side discharge channel 4 is set at the top of the low side discharge channel 5 through the setting of the turning gradient section-3, at the near end of the double channel. , and through the setting of the turning transition section two 6 and the turning transition sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com