Fabricated aluminum-plastic co-extrusion energy-saving auxiliary frame structure

A prefabricated, aluminum-plastic technology, applied in the direction of building components, frame fixing, sealing devices, etc., can solve the problems of damaged and deformed auxiliary frame structures, burning and deformation of auxiliary frame structures, and difficulties, so as to avoid difficult replacement and avoid Effortless to use and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

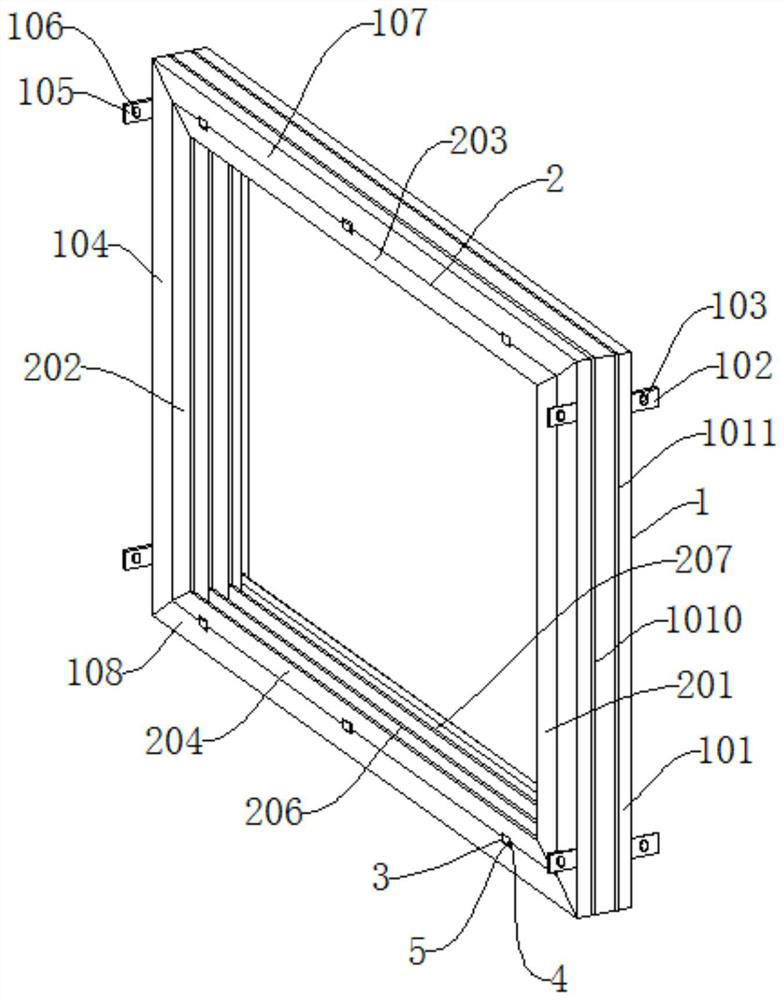

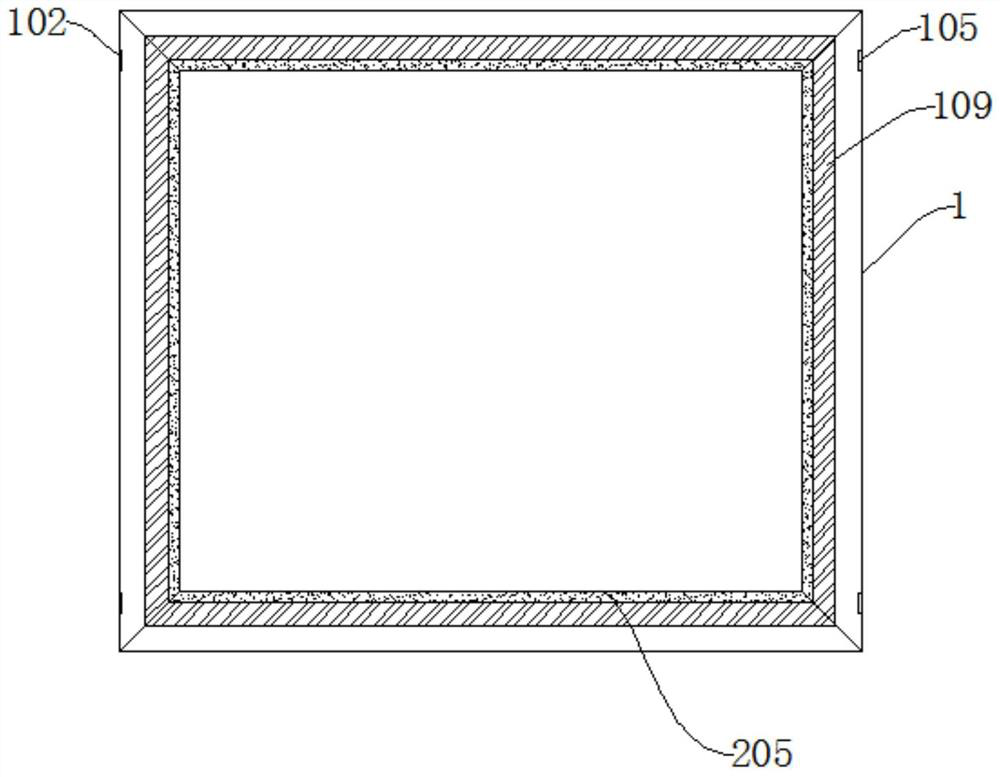

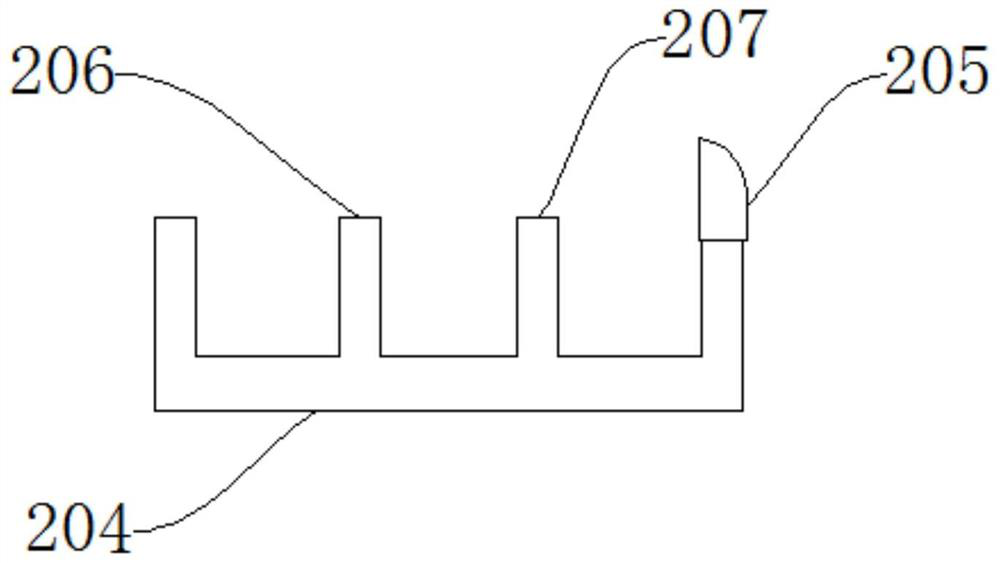

[0038] Such as Figure 1-Figure 5 As shown, an assembly-type aluminum-plastic co-extruded energy-saving auxiliary frame structure includes an outer frame 1, a fixed plate 102 and a dust-proof strip 205. One side of the outer frame 1 is provided with a vertical bar 101, and the vertical bar One side wall of one 101 is provided with said fixing plate one 102, said fixing plate one 102 middle part is provided with fixing hole one 103, outer frame 1 other side is provided with vertical bar two 104, said vertical bar two 104 one side The wall is provided with a fixing plate 2 105, the vertical strip 104 can make the fixing plate firmly connected, and the middle part of the fixing plate 105 is provided with a fixing hole 2 106, and the fixing hole 2 106 can make the auxiliary frame easy to install , a horizontal bar 107 is arranged between the vertical bar one 101 and the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com