Double-cylinder horizontally opposed engine

A horizontally opposed, engine technology, applied in the direction of engine components, machine/engine, engine lubrication, etc., can solve the problems of increasing the weight of drones, increasing the weight of engine cylinders, etc., to reduce weight, improve forming efficiency, and improve The effect of the lubricating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

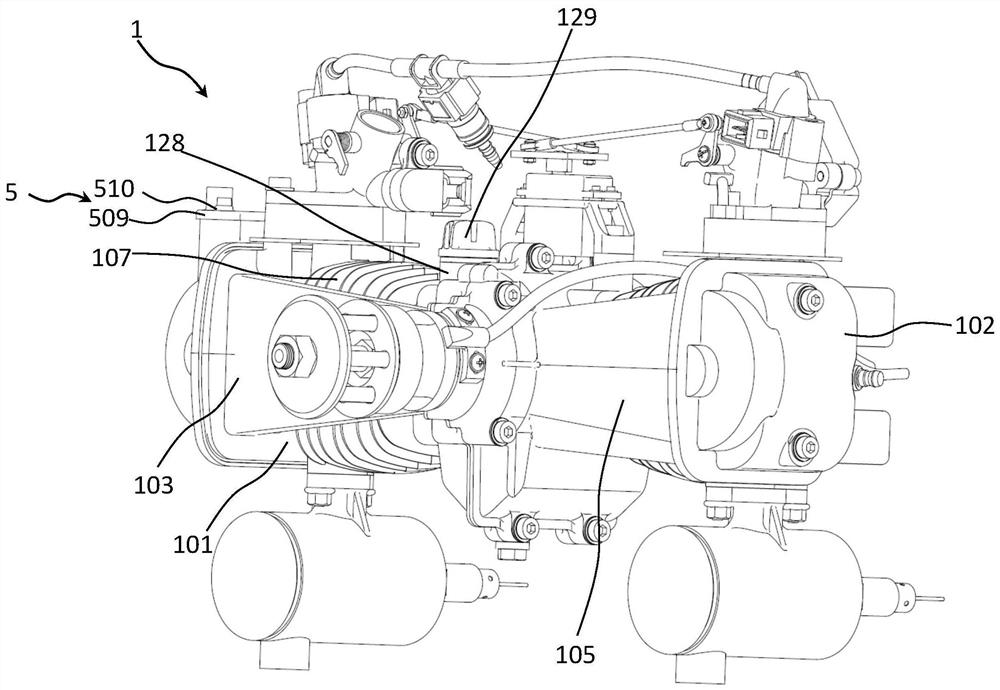

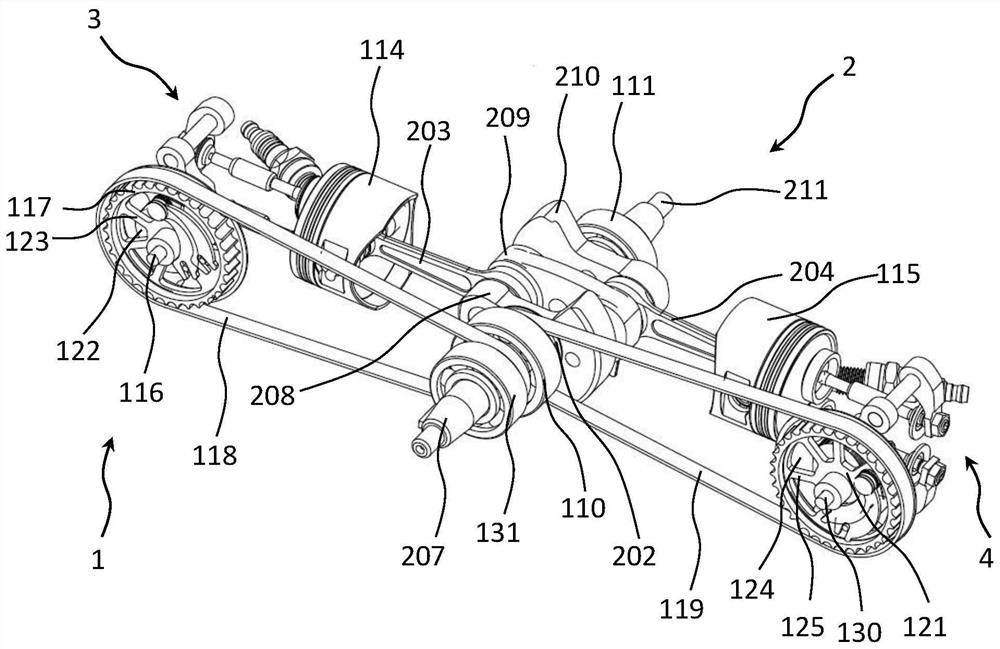

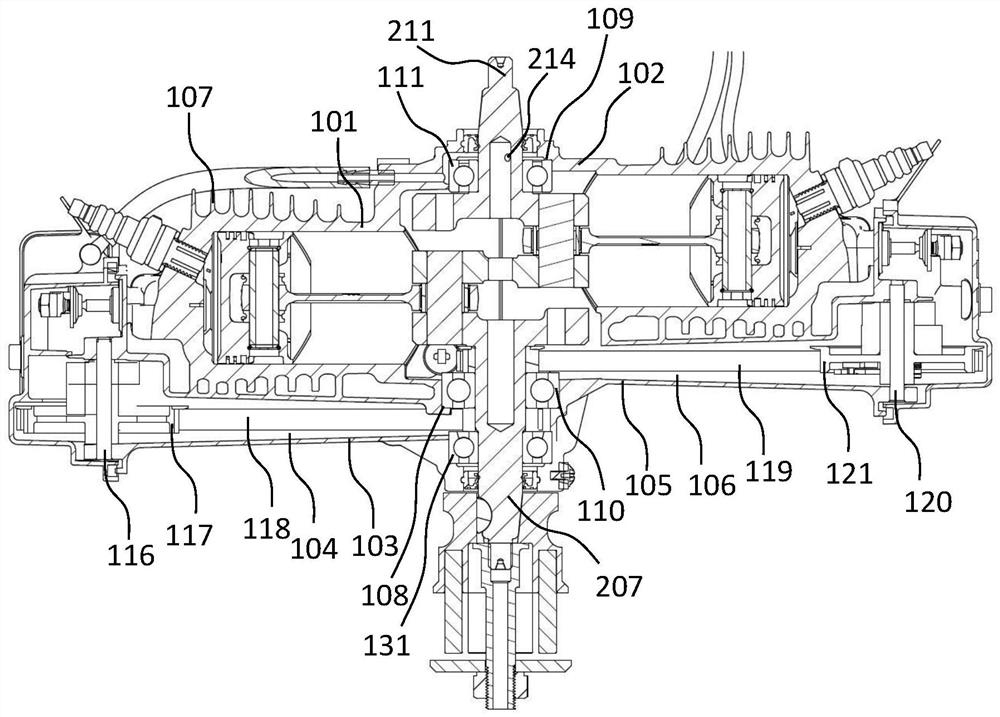

[0032] Such as Figure 1 to Figure 3 as well as Figure 8As shown, a two-cylinder horizontally opposed engine provided in this embodiment includes a cylinder body 1 and a crankshaft 2; the cylinder body 1 includes a first cylinder 101 and a second cylinder 102, and the first cylinder 101 and the second cylinder The two cylinder blocks 102 are connected horizontally. The first cylinder body 101 is provided with a first casing 103, and the first casing 103 is provided with a first channel 104 that runs through it horizontally; the second cylinder body 102 is provided with a second casing 105, and the second casing 105 There is a second channel 106 extending transversely. Both ends of the crankshaft 2 are rotatably connected to the junction of the first cylinder body 101 and the second cylinder body 102 . The crankshaft 2 is provided with a first transmission gear 201 and a second transmission gear 202. The first transmission gear 201 and the second transmission gear 202 are l...

Embodiment 2

[0037] Such as Figure 4 and Figure 5 As shown, the components included in this embodiment and their connections are basically the same as in Embodiment 1, the difference is that the first connecting rod 203 and the second connecting rod 204 are rotatably connected to the crankshaft 2, and the first connecting rod 203 is provided with The first chisel 205 is arranged, the second connecting rod 204 is provided with a second chisel 206; the first cylinder 101 is provided with a first half oil storage chamber 112 on the side of the second cylinder, and the second cylinder 102 is A second half oil storage chamber 113 is provided on the side of the first cylinder body, and the first cylinder body 101 and the second cylinder body 102 are oppositely connected so that the first half oil storage chamber 112 and the second half oil storage chamber 113 form an oil storage chamber; Both the first throwing ruler 205 and the second throwing ruler 206 are located above the oil storage cham...

Embodiment 3

[0046] Such as Figure 6 As shown, the components included in this embodiment and their connections are basically the same as those in Embodiment 1 and Embodiment 2, except that the crankshaft 2 is provided with an oil return hole 212 in the axial direction, and the oil return hole 212 is connected to the first cylinder The inner cavity of the body 101 is connected; a rotational connection between the cylinder body 1 and the crankshaft 2 is provided with an annular groove 213 coaxial with the crankshaft 2, and the crankshaft 2 is provided with a through hole 214 for communicating with the oil return hole 212 and the annular groove 213 ; The first cylinder 101 is provided with an oil return passage 126 corresponding to the annular groove, and the oil outlet of the oil return passage 126 communicates with the annular groove 213 .

[0047] In this technical solution, the recovered engine oil is sent into the annular groove 213 through the oil return passage 126 for storage. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com