Method and system for measuring mass of residual propellant of propulsion system and medium

A propulsion system and propellant technology, which is applied in the field of measurement, can solve the problems of poor propellant safety, unbalanced propellant in the storage tank, and the propellant quality cannot meet the needs of repeated use, and achieves the effect of ensuring safety and less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

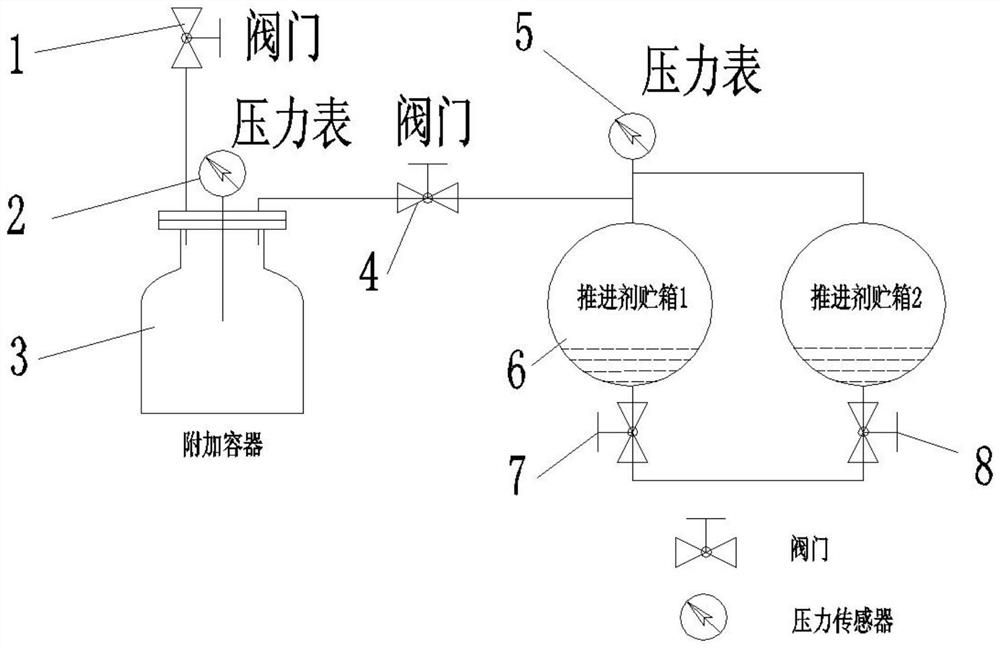

[0043] The invention mainly solves the problem of measuring the residual mass of the propellant in the storage tank under the condition that the propulsion system of the spacecraft does not discharge the residual propellant.

[0044] The equipment required for this approach includes:

[0045] Propulsion system tank: there can be one or more tanks, the tanks are well sealed, and the leakage rate is less than 1×10 - 5 Pa·m 3 / s, if it is necessary to measure the total mass of multiple storage tanks at one time, it is necessary to ensure that the air chambers of multiple storage tanks are connected to each other and the pressure is consistent; the pressure of the air chamber and liquid chamber of a single storage tank is consistent;

[0046] Additional pressure vessel: There can be one or more additional pressure vessels, and multiple pressure vessels are connected. The total volume of the additional pressure vessel is as close as possible to the tank of the propulsion system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com