Method for analyzing liquid metal and device for use in this method

A liquid metal and equipment technology, applied in the field of analyzing the composition of liquid metal molten pool, can solve the problems of prolonging the measurement time, impossible to correctly measure the current composition of molten pool, and further analysis, so as to reduce chemical erosion and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

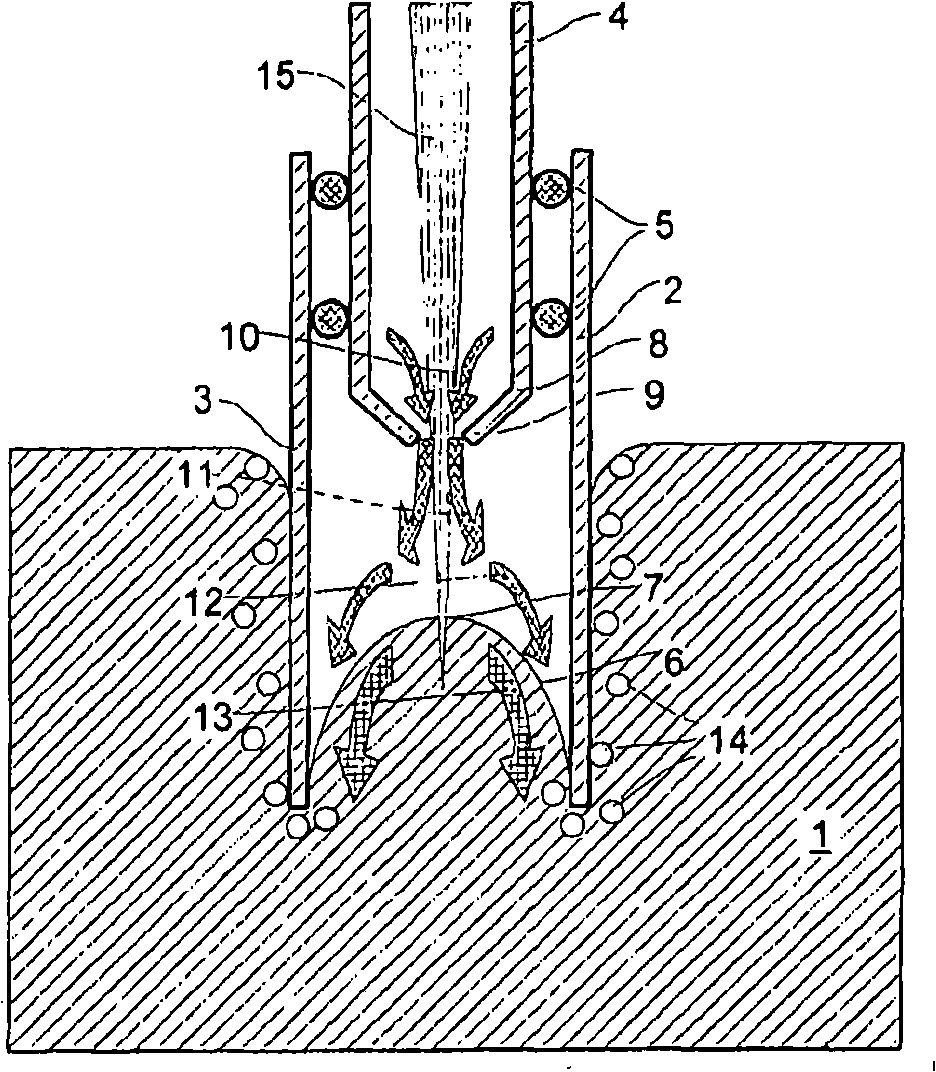

[0038] exist figure 1 In , 1 represents a part of the molten metal pool, such as the molten aluminum alloy pool. The immersion pipe system shown in this example with a jacket 3 extends into the bath. The air supply pipe 4 is concentric with the casing inside the casing. The bushing 3 and the gas supply pipe 4 are connected to each other by an O-ring 5 which also provides a seal against gas leakage.

[0039] As a result of the submersion of a part of the casing 3 into the molten pool 1, a convex meniscus is formed inside the casing. Preferably at least a portion of the inner wall of the sleeve is made of a non-wetting material. A laser beam 15 generated by a laser source (not shown) meets the meniscus at the location of the meeting surface 7 above the focal point of the laser beam to prevent positioning problems and to prevent the gas above the meniscus from forming a plasma.

[0040] The channel 8 of the air supply pipe 4 has a central narrowing 9 .

[0041] The direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com