Return water hydrogen leakage detection sampling device

A sampling device, hydrogen leakage technology, applied in the measurement device, by detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of not seeing the water level of the stainless steel cylinder and measuring the cylinder liquid Poor positioning and accurate control, hydrogen leakage probes are prone to water damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

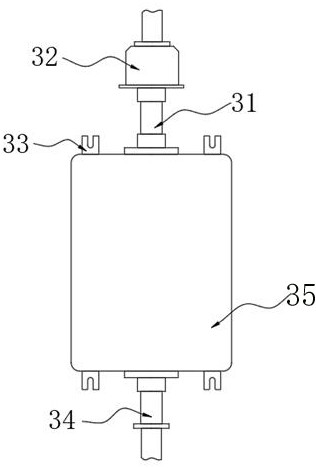

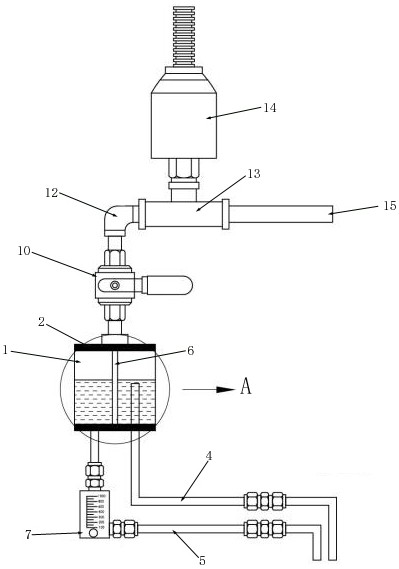

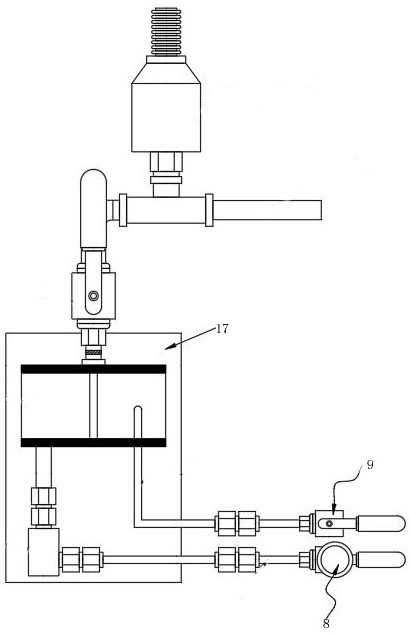

[0032]Such asFigure 2-5As shown, a returning hydrogen rope detects a sampling device, including measuring the cartridge 1, measuring the cylinder is a visible structure, which can be composed of a glass structure, which is designed to facilitate observation of the staff; the measuring cartridge 1 is mounted on the mounting plate 17 On the upper end, the upper end of the measuring cylinder is attached, and the upper cover is provided with an exhaust hole 16, and the upper cover (located below the exhaust hole) is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com