Data monitoring method applied to AOI detection

A data monitoring and detector technology, applied in the direction of optical testing flaws/defects, etc., can solve problems such as inability to effectively detect, product inspection impact, batch inspection, etc., to avoid batch inspection problems, improve inspection accuracy, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

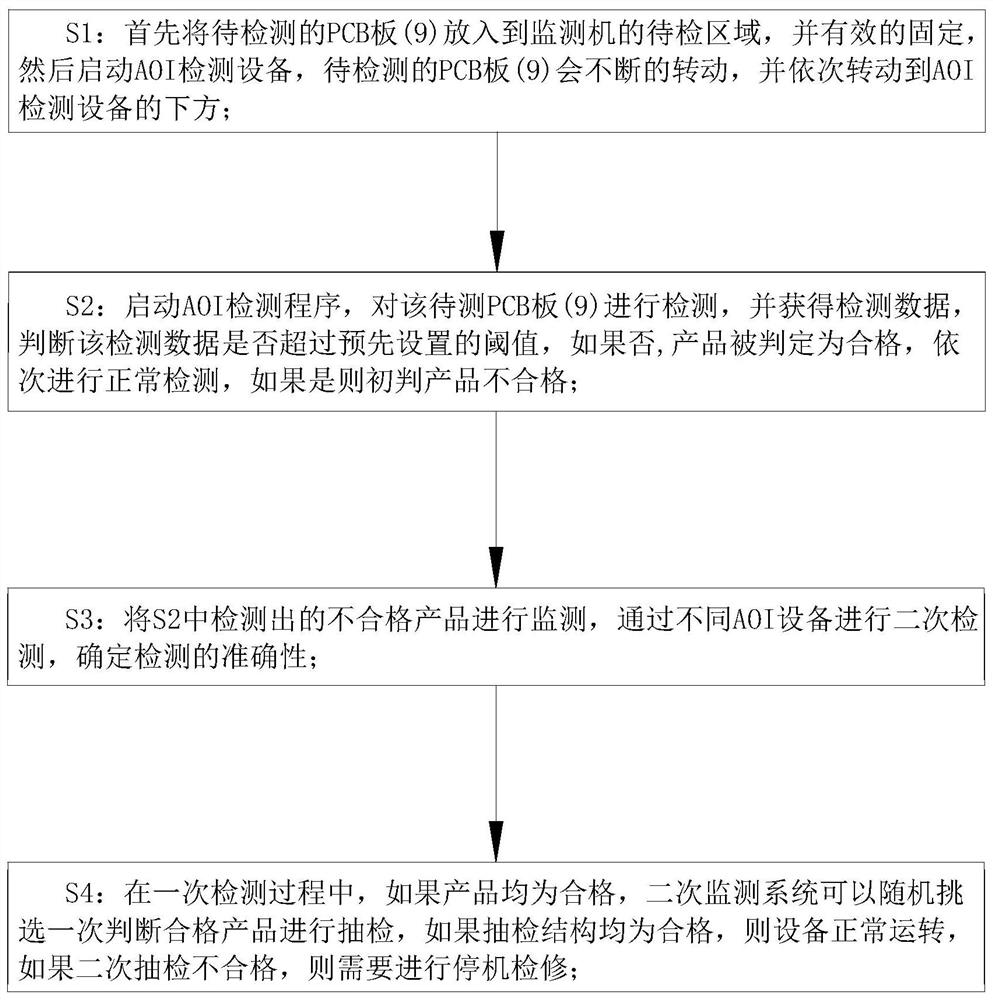

Method used

Image

Examples

Embodiment approach

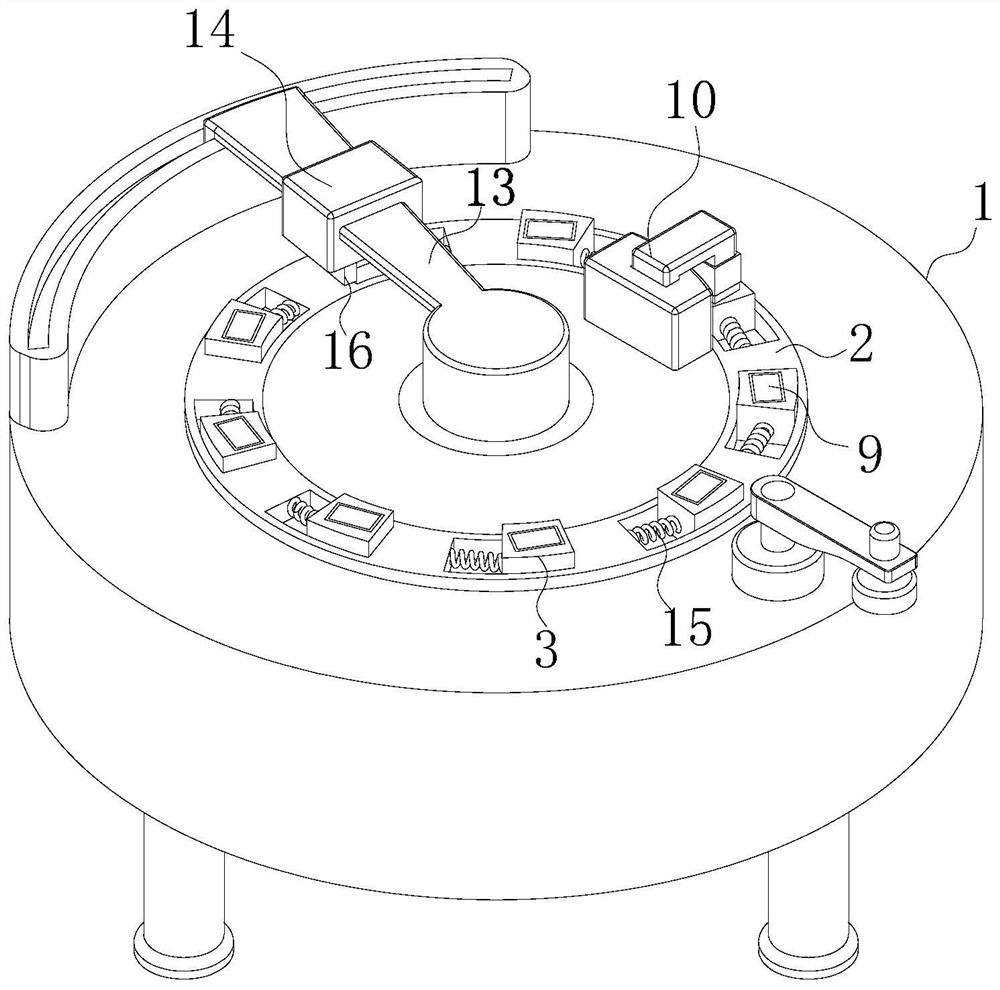

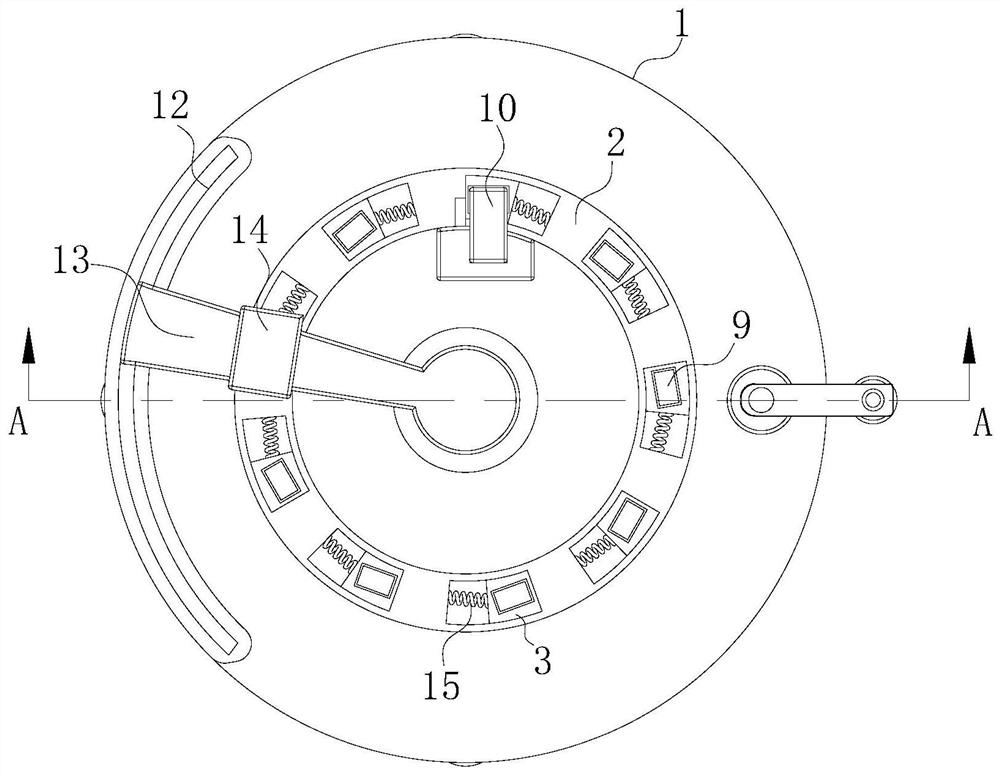

[0040] As an embodiment of the present invention, pressure grooves are provided on the lower surfaces of the first AOI detector 10 and the second AOI detector 14 close to their side positions; pressure blocks 17 are slidably connected to the inside of the pressure grooves. The upper surface of the fixed block 3 is provided with evenly arranged chute; the inside of the chute is slidably connected with a slider 18, and the PCB board 9 is located on the surface of the corresponding slider 18, and the substrate of the PCB board 9 The upper surface is flush with the upper surface of the slider 18; the second spring 19 is fixedly connected between the slider 18 and the groove bottom of the corresponding chute; the first AOI detector 10 and the second AOI detector The lower surface of the device 14 is provided with detection probes; during work, by setting the pressing block 17, when the PCB board 9 is detected, the pressing block 17 is controlled to push out the corresponding pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com