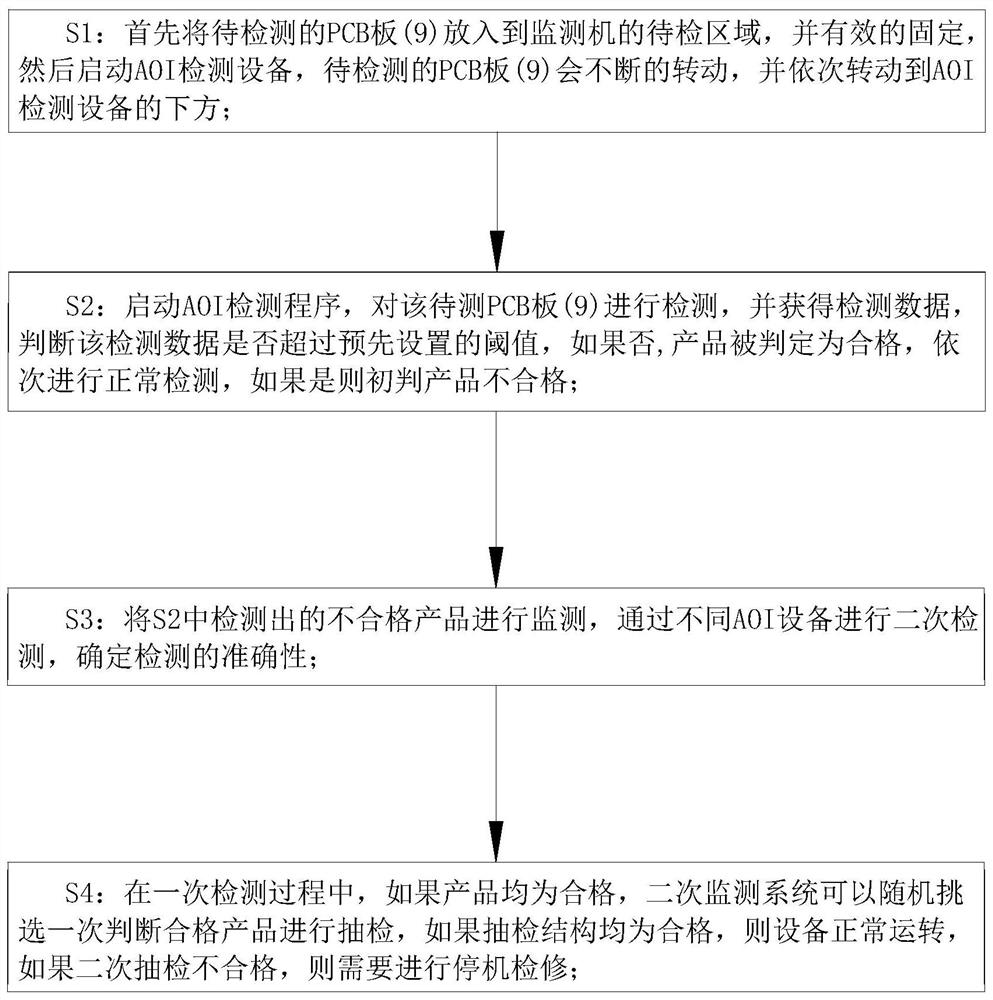

A data monitoring method applied to aoi detection

A data monitoring and detector technology, which is applied in the direction of optical testing flaws/defects, etc., can solve problems such as product testing influence, ineffective testing, product defects, etc., to improve detection accuracy, avoid batch detection problems, and improve accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

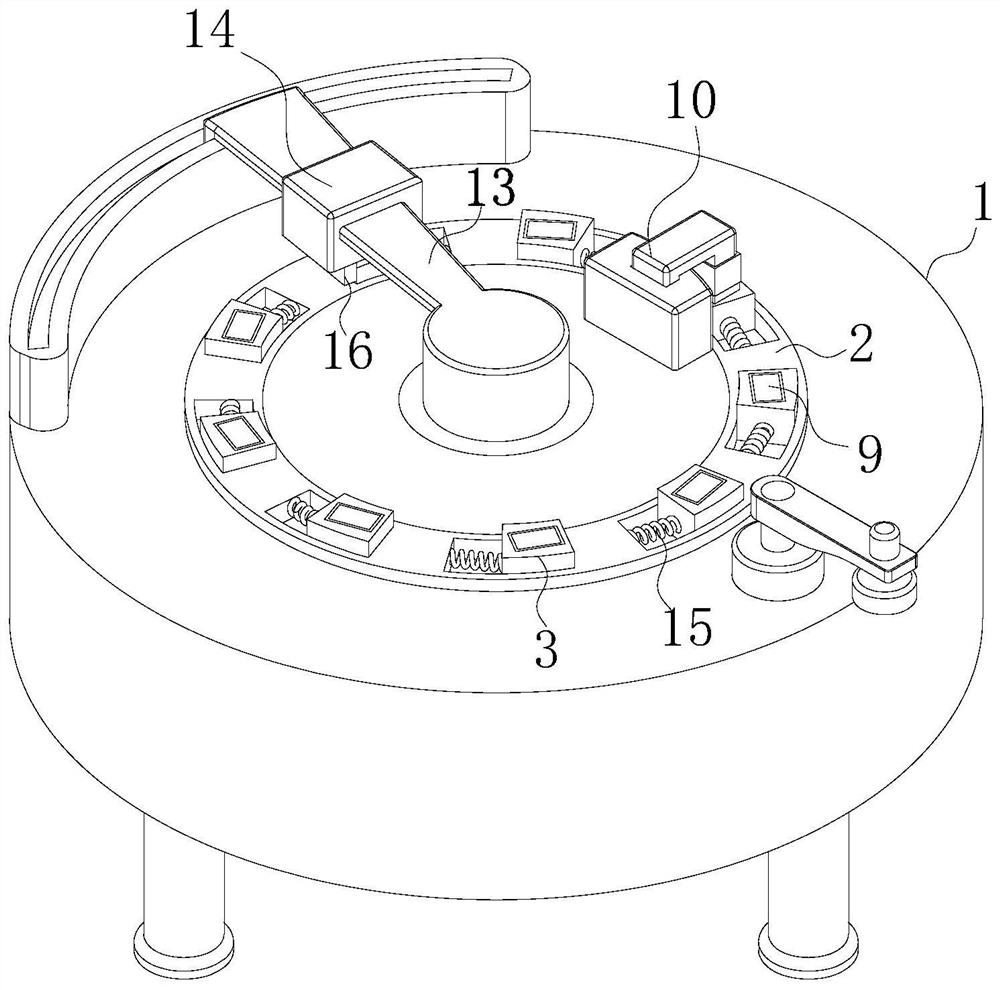

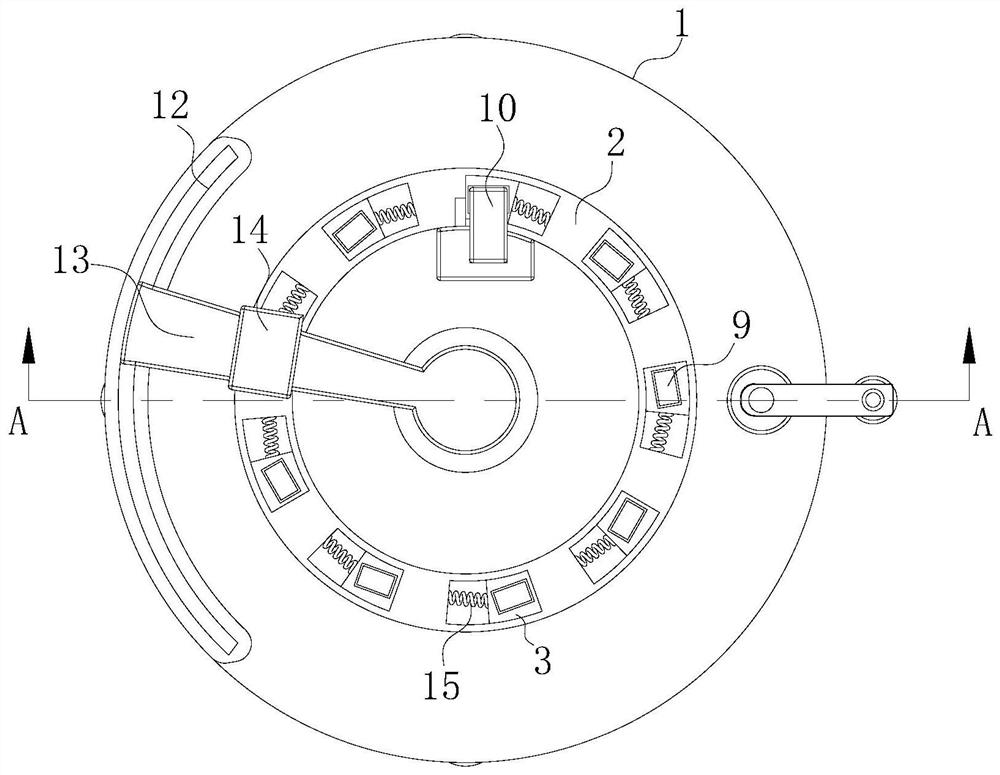

[0040] As an embodiment of the present invention, the lower surface 10 of the first detector and the second AOI AOI detector 14 are close to its lateral position defines a pressure groove; internal pressure of the tank 17 are slidably connected to a briquetting ; the fixed block 3 defines an upper surface of the chute are arranged uniformly; the interior of the chute are slidably connected to the slider 18, the PCB 9 and the surface of the corresponding slider 18 is located, and the PCB substrate 9 between the upper surface 18 flush with the upper surface of a slider; slider 18 between the bottom of the chute corresponding to each fixedly connected with a second spring 19; the first 10 and the second detector AOI detection AOI the lower surface 14 have a detection probe; work, by providing the compact 17, when the detected PCB board 9, by controlling the corresponding pressure briquetting groove 17, thereby pressing down pressure piece 17 will slip block 18, such that the slider 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com