Automatic exposure control method and system

A technology of automatic exposure and control method, applied in the parts of TV system, TV, color TV and other directions, can solve the problems of exposure radiation field and difficult control of exposure dose, and achieve accurate exposure radiation field. , The effect of shortening the sampling cycle and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

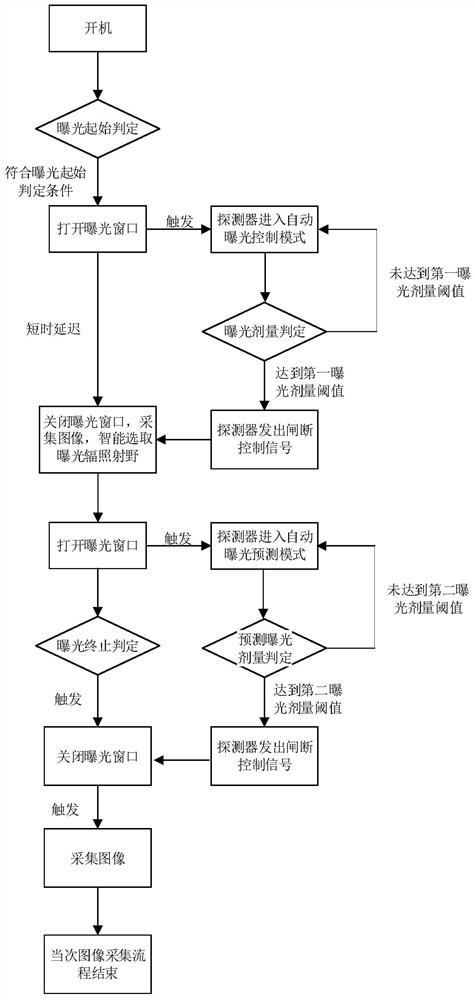

[0047] Such as figure 1 As shown, this embodiment provides an automatic exposure control method, and the automatic exposure control method includes:

[0048] 1) Turn on the flat panel detector, and set the parameters of the flat panel detector.

[0049]Specifically, first place the flat panel detector in the detection system and electrically connect it with other devices in the detection system. The detection system includes but not limited to DR (Digital Radiography, direct digital X-ray), CT (computed tomography, electronic Computed tomography) and security inspection machines, any system that uses flat panel detectors for image acquisition is applicable.

[0050] Specifically, the flat panel detector is turned on, and the parameters of the flat panel detector are set. The set parameters include but not limited to the exposure dose threshold and other parameters to ensure the normal operation of the flat panel detector, which are not limited to this embodiment. Step 2) aft...

Embodiment 2

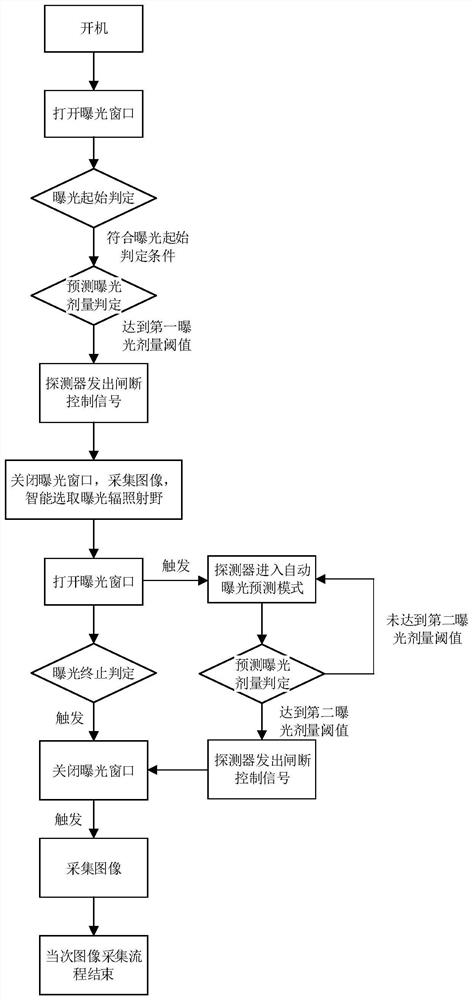

[0065] Such as figure 2 As shown, this embodiment provides an automatic exposure control method. The difference from Embodiment 1 is that the automatic exposure control method detects the exposure by scanning the exposure dose of the exposure radiation field area of the flat panel detector. Start time, and control the exposure dose of the first image acquisition (for determining the exposure radiation field) by predicting the exposure dose at the end of the image acquisition, including the following steps:

[0066] 1) Turn on the flat panel detector, and set the parameters of the flat panel detector.

[0067] For the specific method, refer to Embodiment 1, which will not be repeated here.

[0068] 2) Real-time detection of the exposure start time, the exposure dose is detected after the exposure starts and the exposure dose at the end of the exposure is predicted. If the exposure dose at the end of the exposure is predicted to reach the first exposure dose threshold, the e...

Embodiment 3

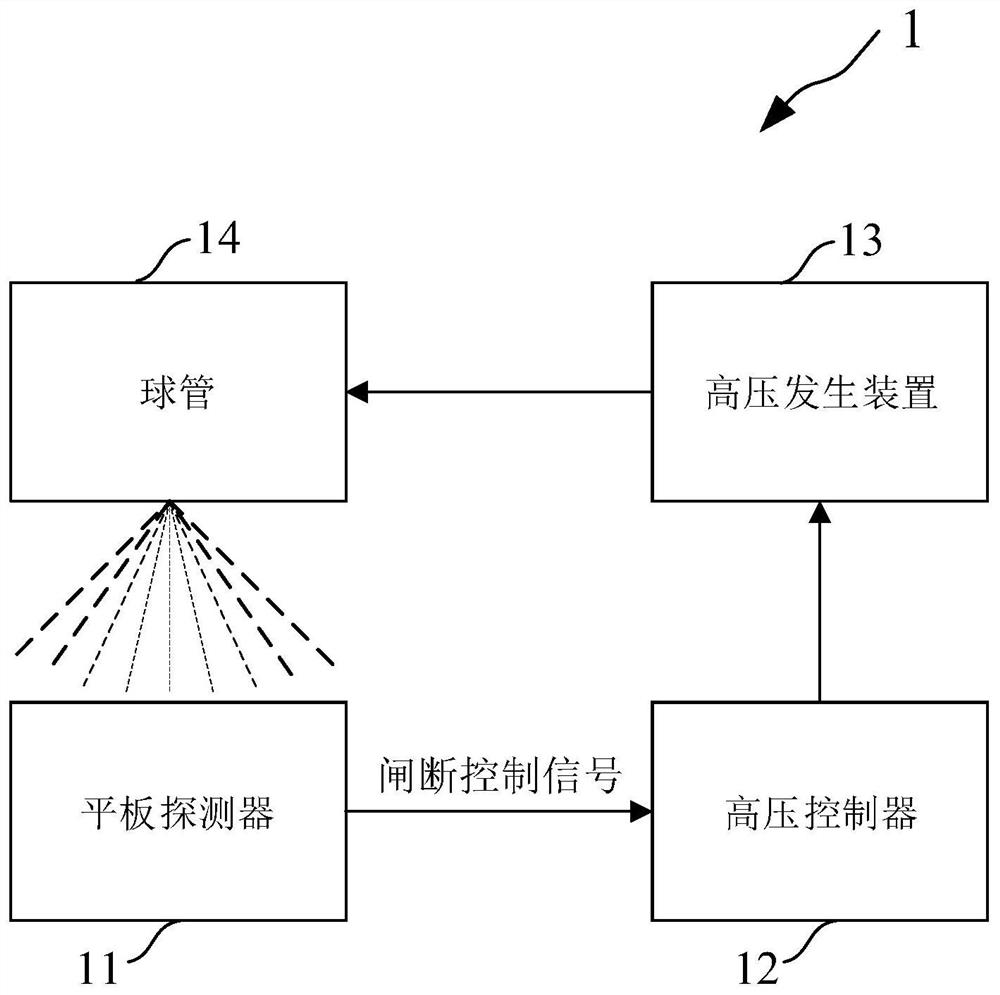

[0077] Such as Figure 3 ~ Figure 5As shown, this embodiment provides an automatic exposure control system 1. In this embodiment, the automatic exposure control system 1 is used to implement the automatic exposure control method described in Embodiments 1-2. The automatic exposure control system 1 includes:

[0078] A flat panel detector 11 , a high voltage controller 12 , a high voltage generating device 13 and a ball tube 14 .

[0079] Such as image 3 As shown, the flat panel detector 11 implements automatic exposure control and automatically collects images.

[0080] Specifically, as Figure 4 As shown, the flat panel detector 11 includes a detection panel 111, an exposure radiation field calculation module 112 and an automatic exposure control module 113; the detection panel 111 detects X-rays and converts them into electrical signals; the exposure radiation The field calculation module 112 is connected to the output terminal of the detection panel 111, and determines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com