Printed circuit board, display module and LED display screen

A technology of LED display screen and printed circuit board, which is applied in the direction of printed circuit, printed circuit parts, printed circuit connected with non-printed electrical components, etc. PCB pad position offset and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

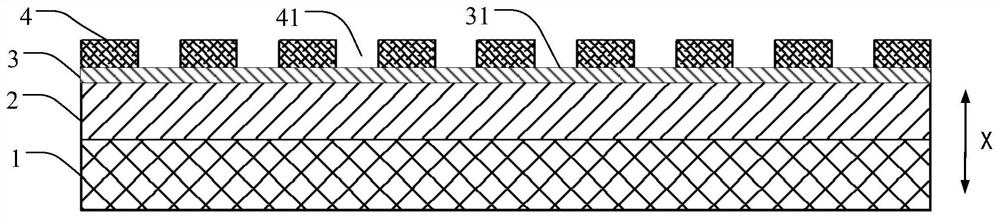

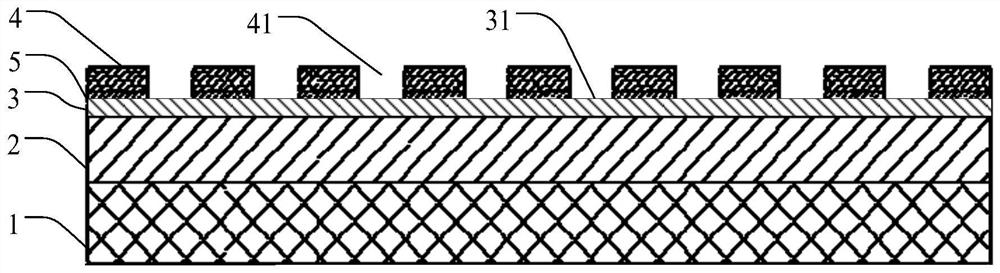

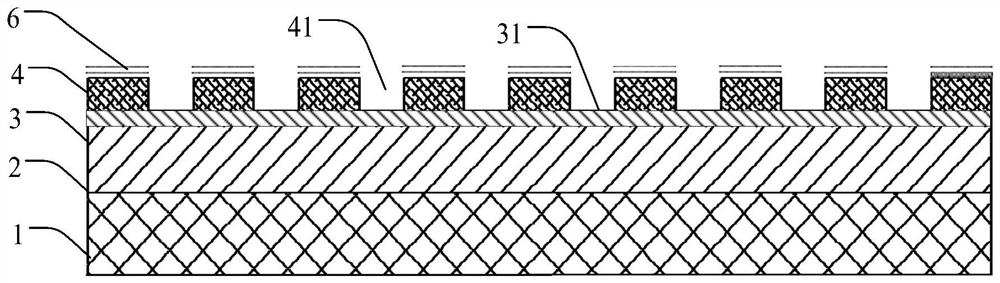

[0067] The first implementation mode:

[0068] see Figure 4 ,and Figure 4 The direction in is for reference. It can be seen that the printed circuit board includes the fourth prepreg layer, the first copper foil layer 3, the first prepreg layer 2, the copper clad laminate layer 1, the second prepreg layer 7, and the second copper foil layer stacked in sequence from top to bottom. Foil layer 8 and fifth prepreg layer. That is, in this embodiment, the first insulating layer 4 is the fourth prepreg layer, and the second insulating layer 9 is the fifth prepreg layer.

[0069]The first copper foil layer 3 has a first pad 31 , and the fourth prepreg layer is provided with a first through hole 41 penetrating through the thickness direction; the first pad 31 is located in the first through hole 41 . The second copper foil layer 8 has a second pad 81 , and the fifth prepreg layer is provided with a fourth through hole 91 penetrating through the thickness direction; the second pad ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com