Iron plate stamping device capable of achieving automatic equidistant feeding

A punching device and equidistant technology, applied in the field of iron plate punching devices with distance feeding, can solve the problems of large workload, prone to deviation, low efficiency, etc., and achieve the effect of improving utilization rate, preventing dispersion and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

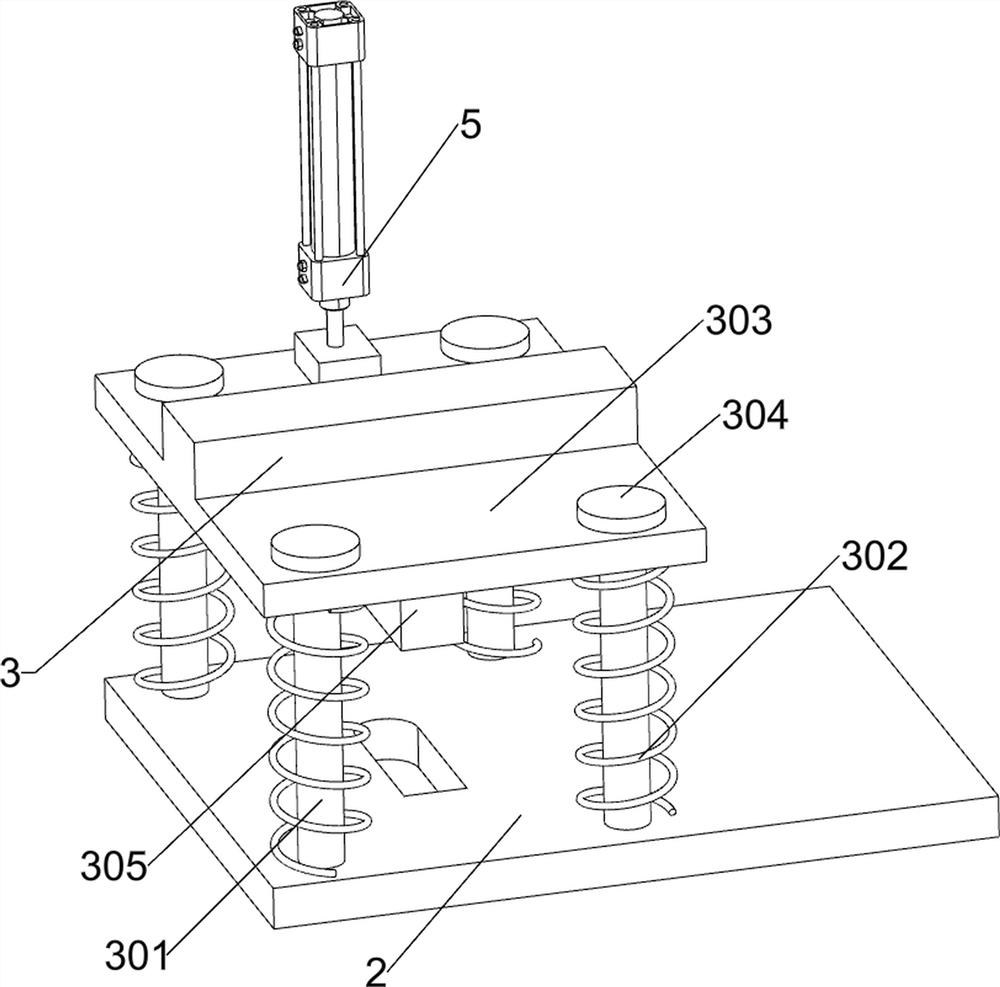

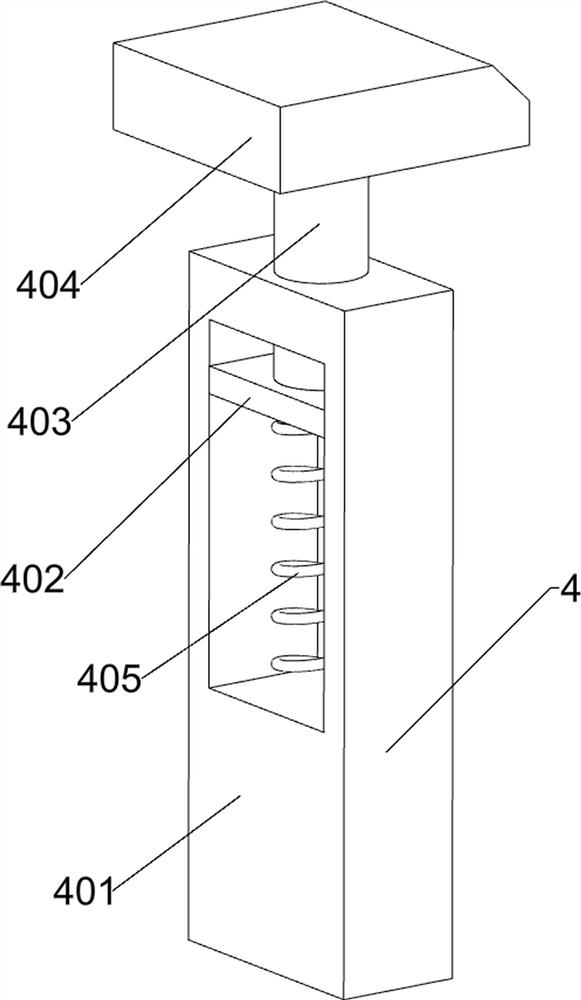

[0032]An automatic equidistant feed iron plate stamping device, such asFigure 1-4As shown, the base 1, the table 2, the stamping assembly 3, the one-way assembly 4, and the cylinder 5 are included, and the table 2 is mounted in the middle of the top of the base 1, and the stamping assembly 3 is mounted on the table 2, and the bottom left side of the base 1 is connected. There is a one-way assembly 4, and the cylinder 5 is mounted on the top of the base 1.

[0033]The stamping assembly 3 includes a first guide bar 301, a first spring 302, a first movable plate 303, a first baffle 304, and a punching block 305, and a first guide bar 301, a first guide bar 301. The sliding connection has a first movable plate 303, and the first movable plate 303 is located below the bump of the cylinder 5, and the first spring 302 is connected between the first movable plate 303 and the table 2, and the first spring 302 is set in the first guide. On the outer side of the rod 301, the first baffle 304 is c...

Embodiment 2

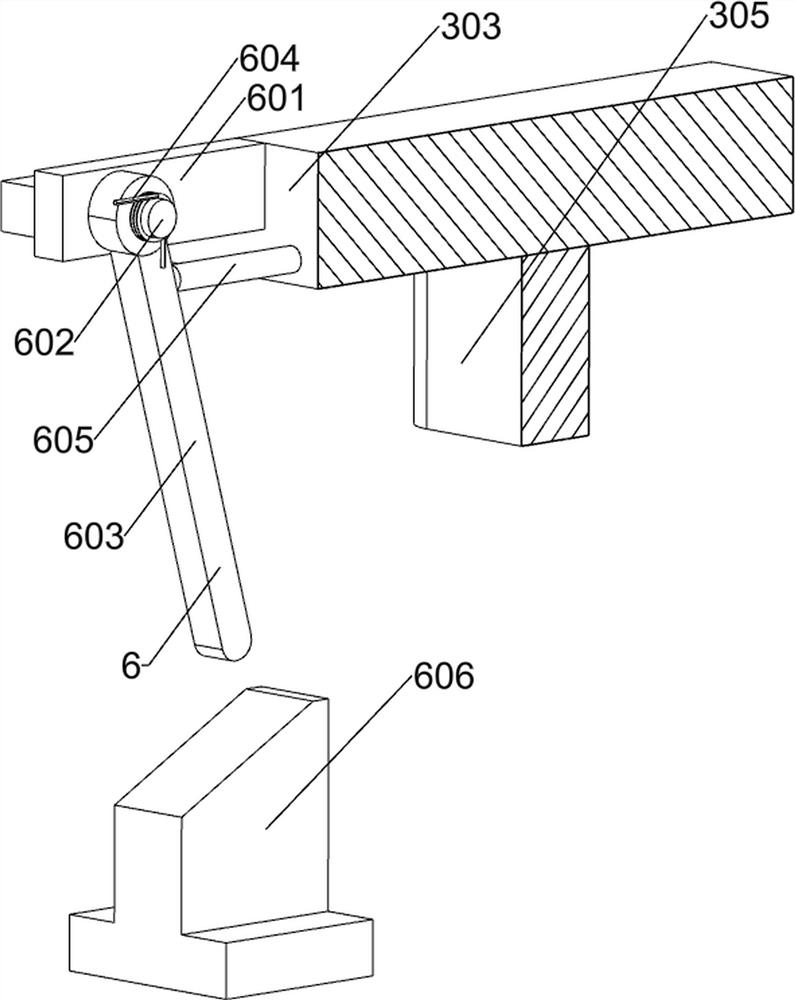

[0037]On the basis of Example 1, such asFigure 5 The moving assembly 6 is also included, and the moving assembly 6 includes a first support plate 601, a second support rod 602, a first contact rod 603, a torsion spring 604, a second contact rod 605, and a first contact block 606, The first support plate 601 is connected to the left side of the movable plate 303, and a second support rod 602 is connected between the first support plate 601, and the second support rod 602 is rotatably connected to the first contact rod 603, the first support plate. 601 is connected between the first contact rod 603, and the first movable plate 303 is connected to the left side of the first contact rod 603 in contact with the second contact rod 605, and the top of the base 1 is connected There is a first contact block 606, and the first contact block 606 is located below the first contact rod 603.

[0038]When the first movable plate 303 moves downward, the first support plate 601 moves downward with the ...

Embodiment 3

[0040]On the basis of Example 2, such asFigure 6 The collecting assembly 7 is also included, and the collecting assembly 7 includes a guide rail 701, a collection chamber 702, a second baffle 703, a connecting plate 704, a connecting rod 705, and a handle 706, a base 1 intermediate connection with a guide rail 701, guide rail 701 The collected box 702 is slidably connected, and the collecting box 702 is located below the punching block 305, and the rail 701 is connected to the back side of the guide rail 703, and the front side of the collecting box 702 is connected to the connecting plate 704, and the connecting plate 704 is connected to a connecting rod. 705, the connecting rod 705 is connected to the handle 706.

[0041]The material that is stamped will fall into the collecting box 702 at the through hole on the workbench 2, and after collecting the handle 706, the handle 706 pulls the collected frame out, the collection box slides on the guide rail 701, and the material within the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com