Welding power source deep penetration welding machine

A welding power supply and deep penetration welding technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of different widths of the front side of the weld, poor welding quality, and large height errors, so as to improve production yield. , Improve stability and avoid crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

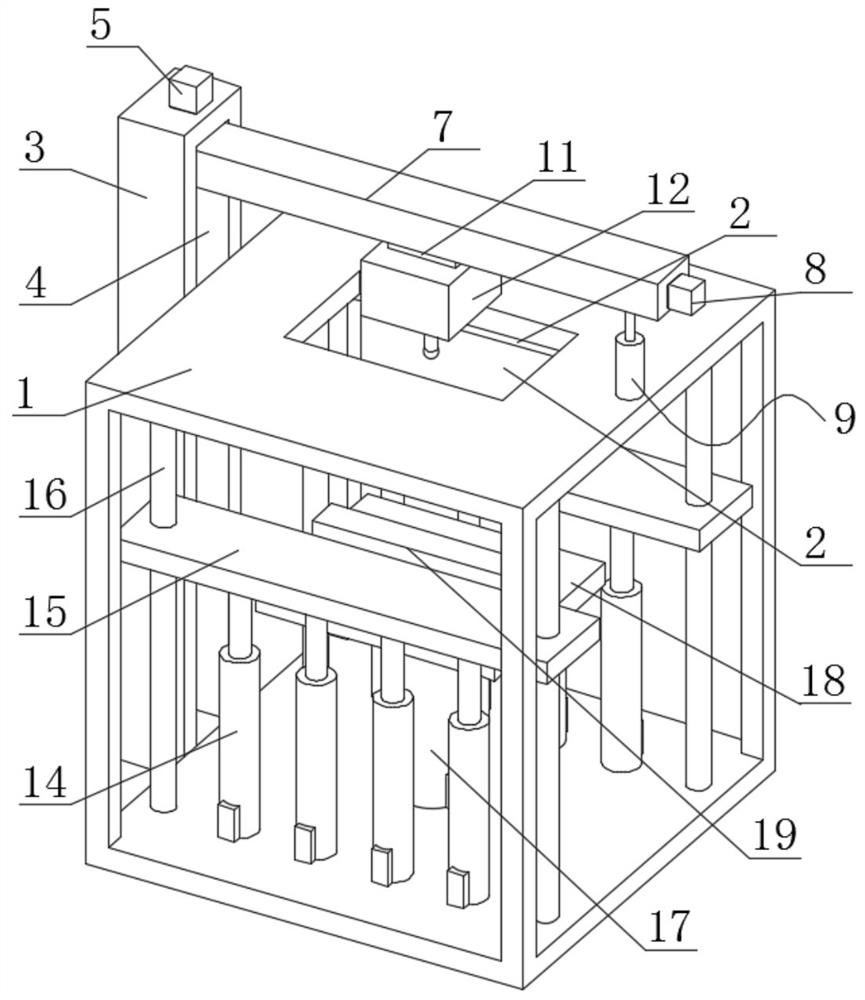

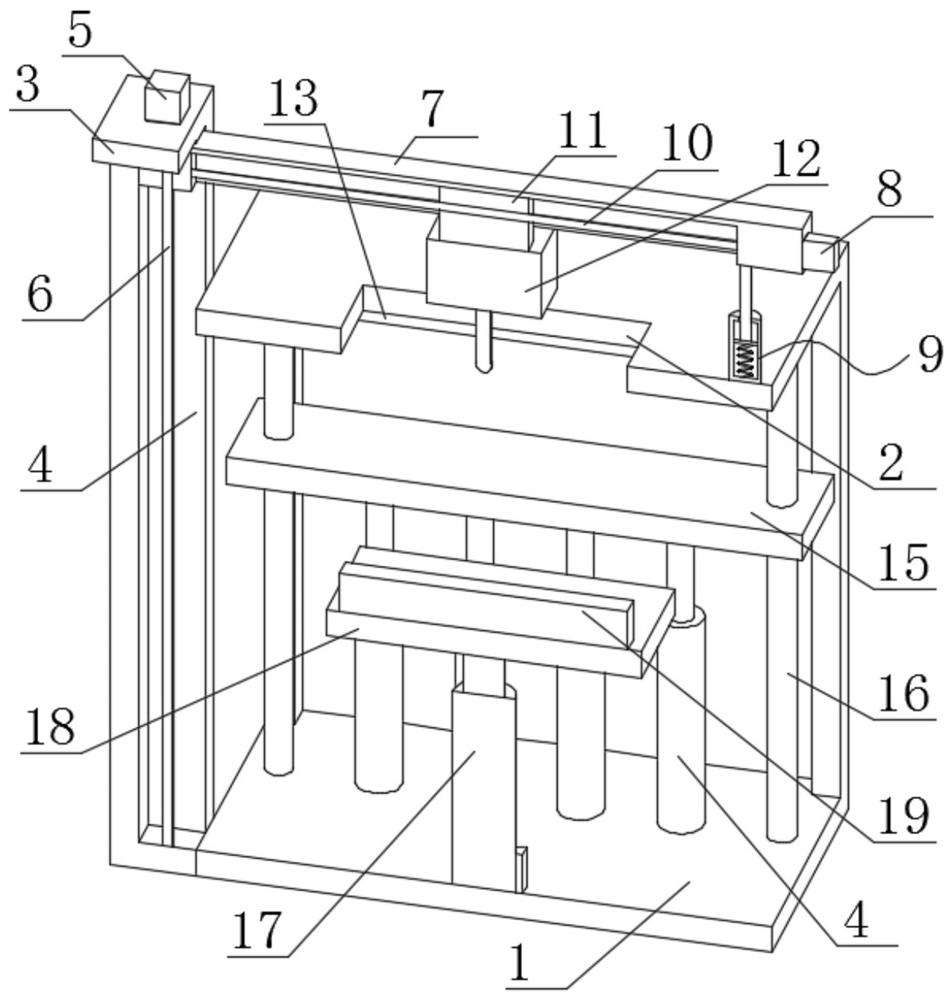

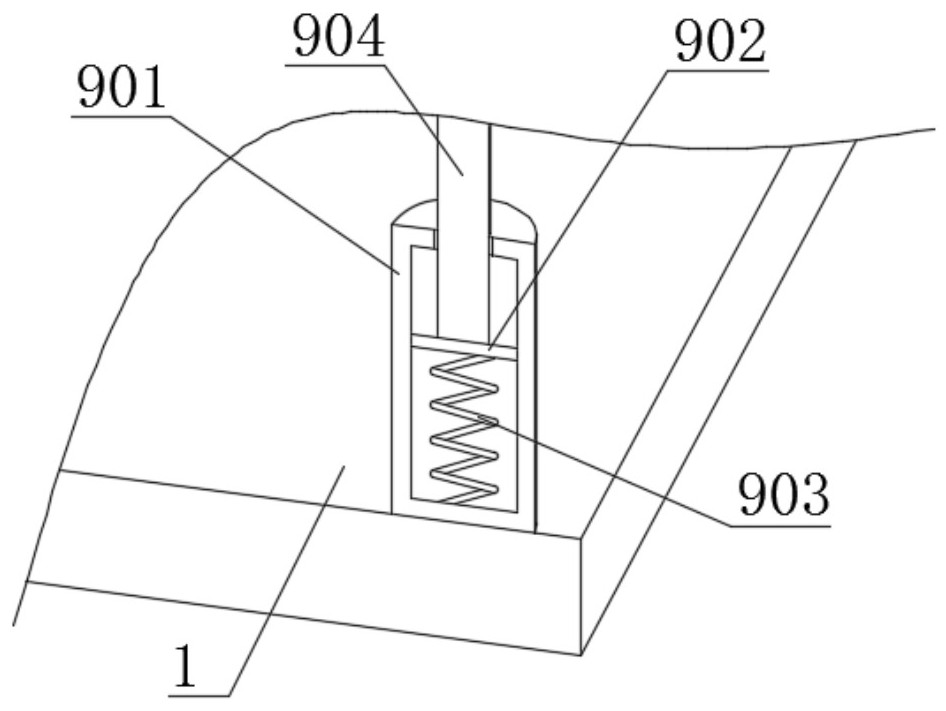

[0018] Such as Figure 1-3 As shown, the embodiment of the present invention provides a welding power supply deep penetration welding machine, including a housing 1, the center of the inner bottom wall of the housing 1 is fixedly connected with a second hydraulic cylinder 17, and the telescopic end of the second hydraulic cylinder 17 is fixedly connected There is a fixed plate 18, the top surface of the fixed plate 18 is fixedly connected with an argon gas protection box 19, and the inner bottom wall of the housing 1 is fixedly connected with two sets of symmetrical first hydraulic cylinders 14, and the inside of the housing 1 is provided with two A lower clamping plate 15, the telescopic end of each first hydraulic cylinder 14 is all fixedly connected with the bottom surface of the lower clamping plate 15, and the inside of the two lower clamping plates 15 is all slidably connected with two guide rods 16, each The two ends of the guide rod 16 are respectively fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com