Server PCBA welding and pressing device

A technology of pressing device and server, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low work efficiency, inconvenient production process, low product qualification rate, etc., and achieve product qualification rate improvement and practicability. The effect of high, overall convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

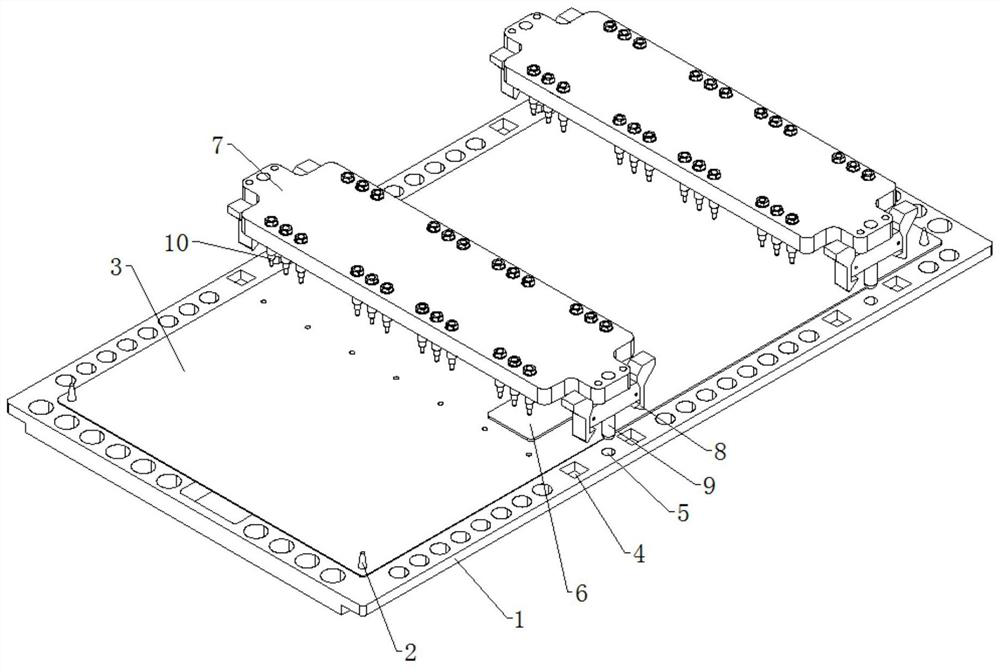

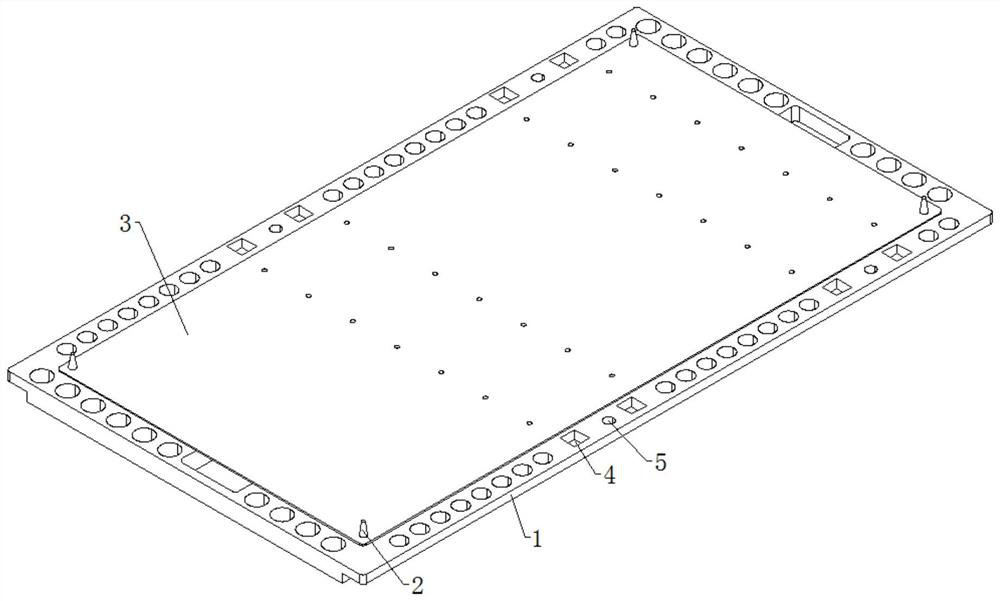

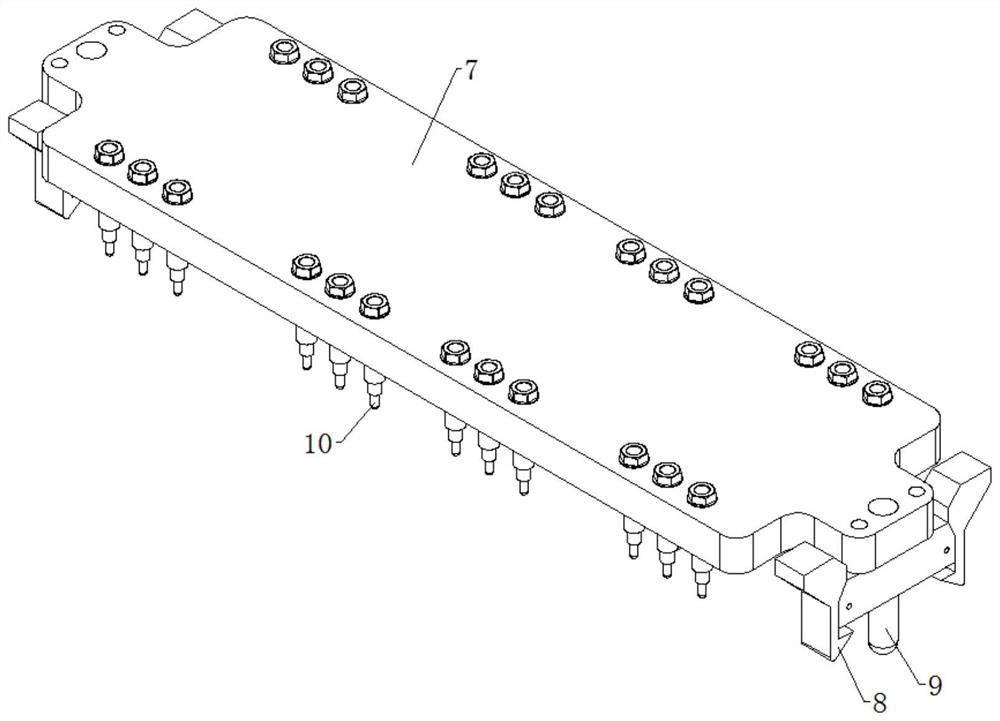

[0020] Examples, see Figure 1-3 , the present invention provides a technical solution: a server PCBA welding and pressing device, including a fixture base 1, a limit rod 2 is arranged at the corner of the upper surface of the fixture base 1, and the upper surface of the fixture base 1 passes through the limit rod 2 The 5GMOB PCB board 3 is connected, the upper surface of the fixture base 1 and the front and rear sides of the 5GMOBPCB board 3 are correspondingly provided with card slots 4, the upper surface of the fixture base 1 and the inner side of the card slot 4 are correspondingly provided with through holes 5 , the upper surface of the 5GMOB PCB board 3 is correspondingly provided with a PAM board 6, the upper surface of the fixture base 1 and located above the 5GMOBPCB board 3 is correspondingly provided with a fixture gland 7, and the front and rear sides of the bottom of the fixture gland 7 are correspondingly arranged There are buckles 8, the front and rear sides of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com