Conveniently moved forming equipment for PVC building material

A technology for forming equipment and building materials, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve the problems of non-irritating gas filtration, no support seat, no filter box, etc., to achieve safe and convenient use, reduce The degree of pollution, the effect of avoiding rollover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

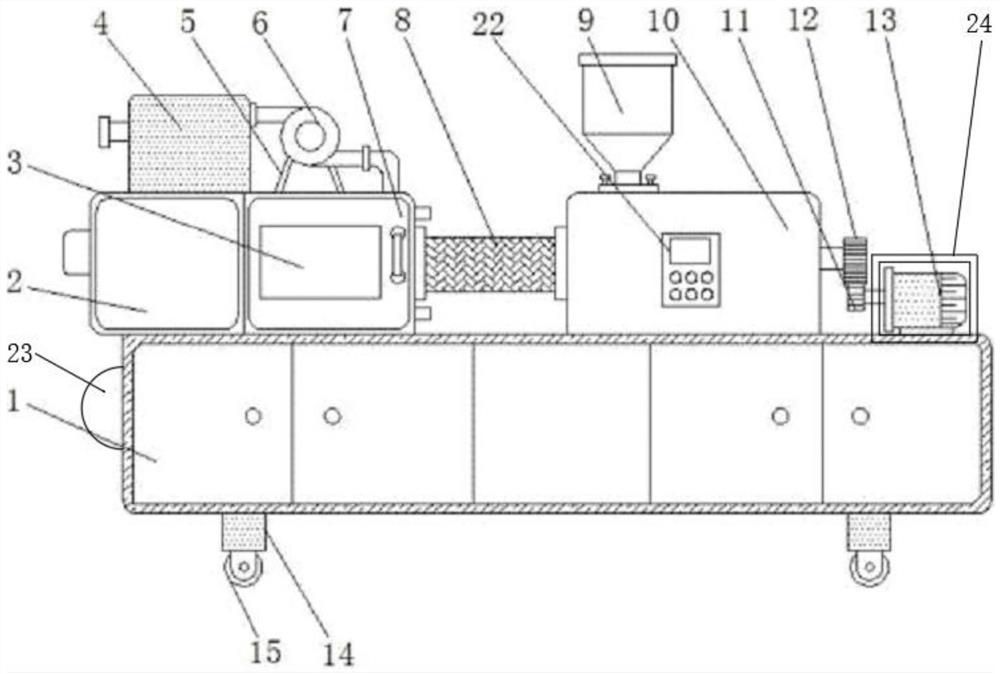

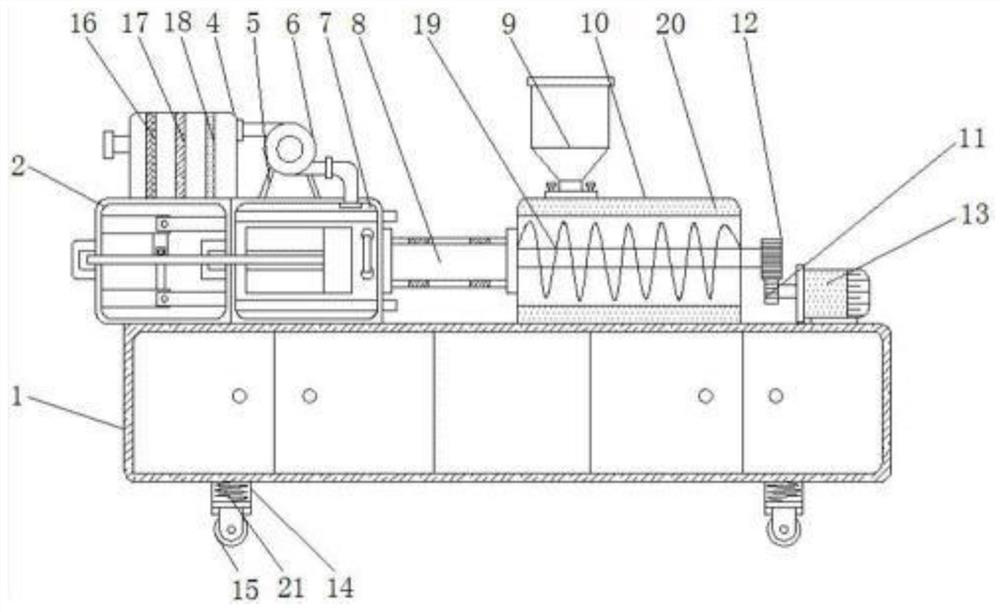

[0014] Example: such as Figure 1-2 As shown, the present invention provides a technical solution, a molding equipment for PVC building materials that is easy to move, including an injection molding machine body 1, a transmission box 2, an observation window 3, a filter box 4, a bracket 5, a fan 6, and a clamping box 7. Cylinder 8, hopper 9, injection cavity 10, pinion 11, large gear 12, servo motor 13, support seat 14, pulley 15, catalyst filter 16, activated carbon filter 17, primary filter 18, auger 19 , a sound-absorbing board 20, a spring 21 and a PLC controller 22, the side of the injection molding machine body 1 is fixed with a lighting lamp 23 by bolts, the lighting lamp 23 is powered by an external power supply, and the injection molding machine body 1 is facilitated to move through the lighting lamp 23 The upper end of the injection molding machine body 1 is provided with an injection cavity 10, and the lower end of the injection molding machine body 1 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com