A kind of AGV wireless charging pile system and using method thereof

A wireless charging and charging pile technology, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of charging contact wear, increase labor maintenance costs, spark generation, etc., improve charging efficiency, and avoid equipment volume. and the effect of excessive weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0050] The present invention will be described in detail below with reference to the accompanying drawings and examples.

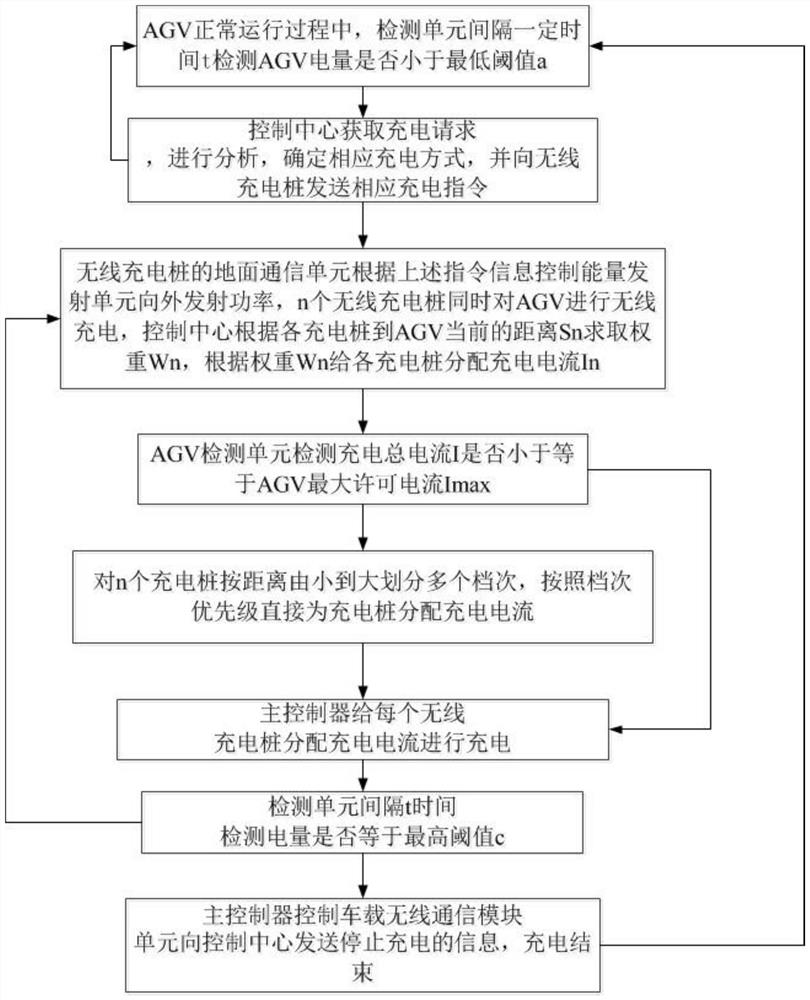

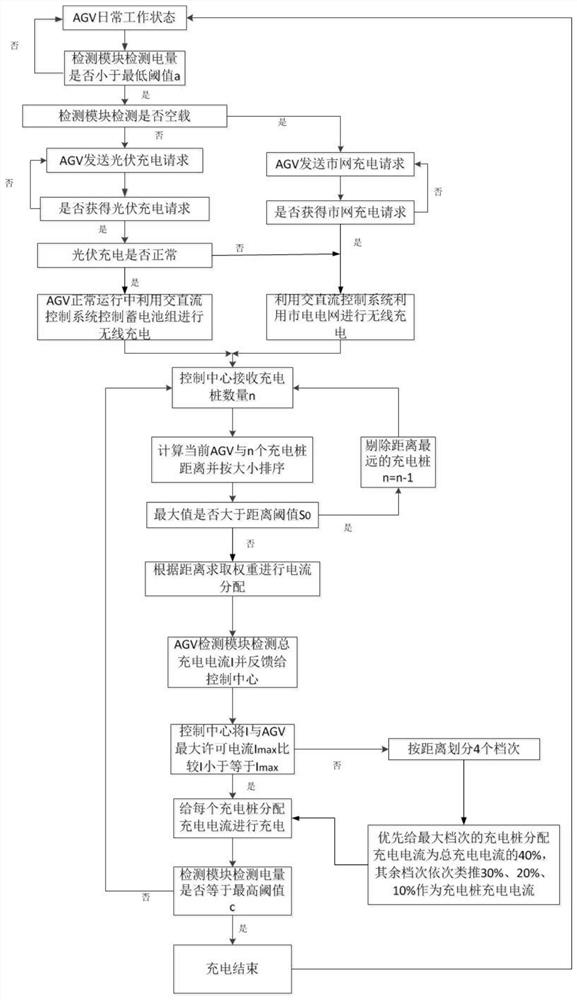

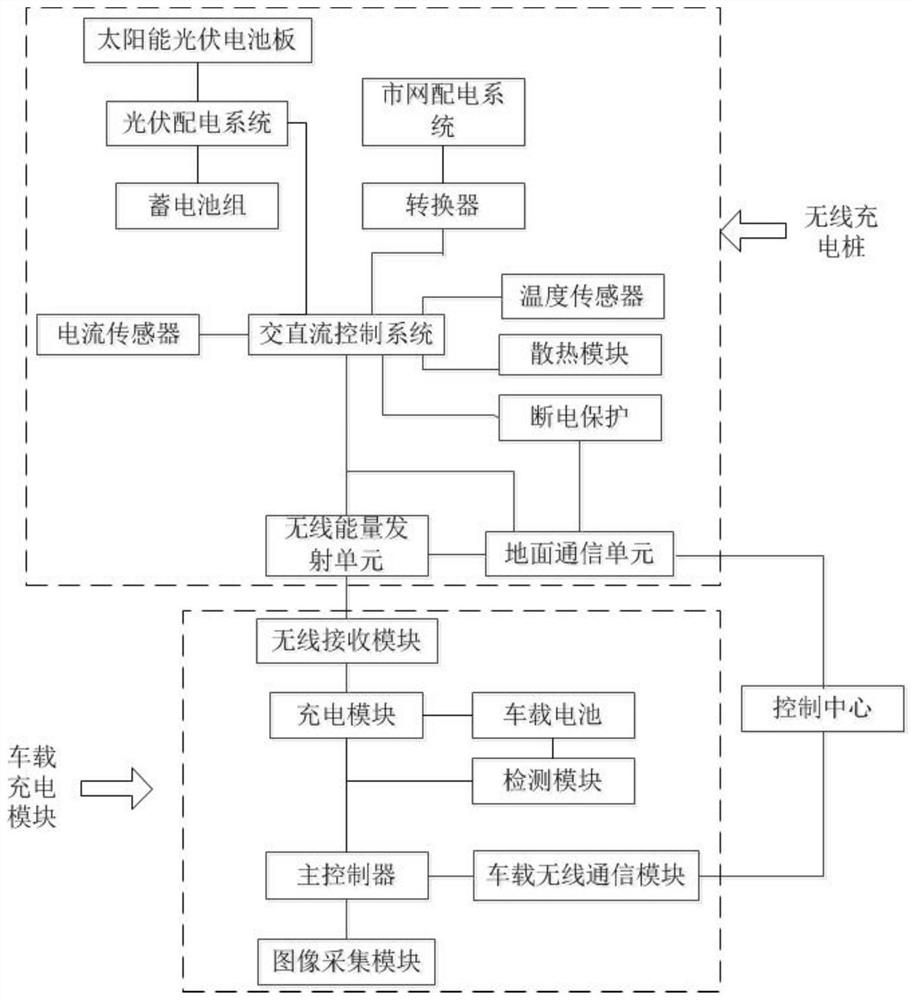

[0051] Such as figure 1 As shown, a method for using an AGV wireless charging pile system includes the following steps:

[0052] S1, during the daily working state of the AGV, the detection module detects whether the AGV power is less than the minimum threshold a at intervals of a certain time t, if less, the main controller on the AGV controls the vehicle-mounted wireless communication module to send a charging request message to the control center, and then transfers to S2, If not, return to S1;

[0053] The S1 also includes a detection module to detect whether the AGV has a load. If there is a load, the main controller on the AGV controls the on-board wireless communication module t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com