Integral bridge abutment and steel beam combined part structure

An integral bridge abutment and joint technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as affecting the quality of concrete pouring, reducing economic benefits, and unclear stress, and improving construction efficiency and economic benefits. Improve economic efficiency and the effect of clear force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

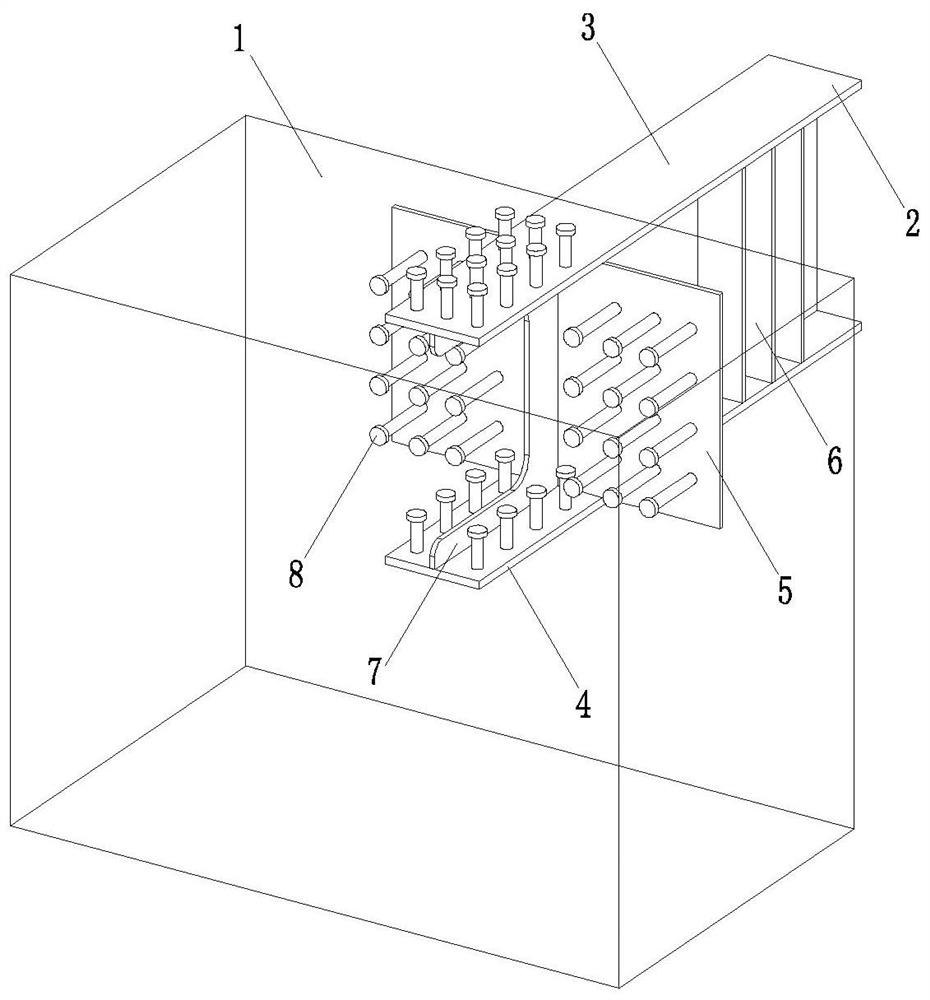

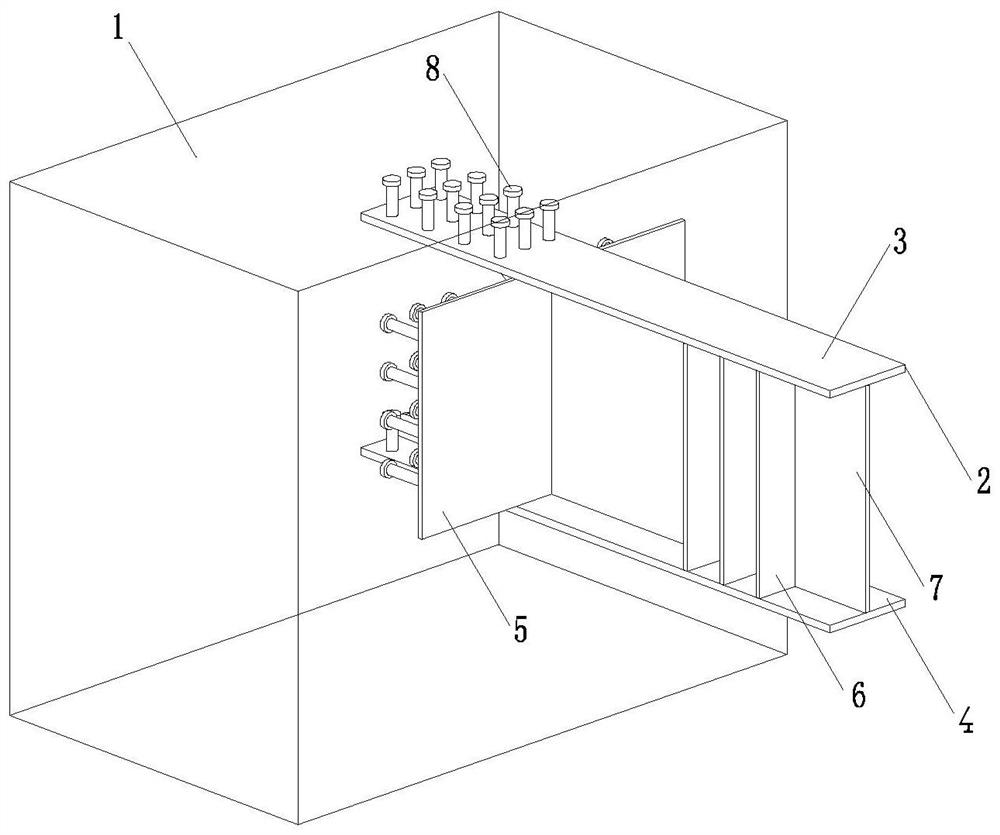

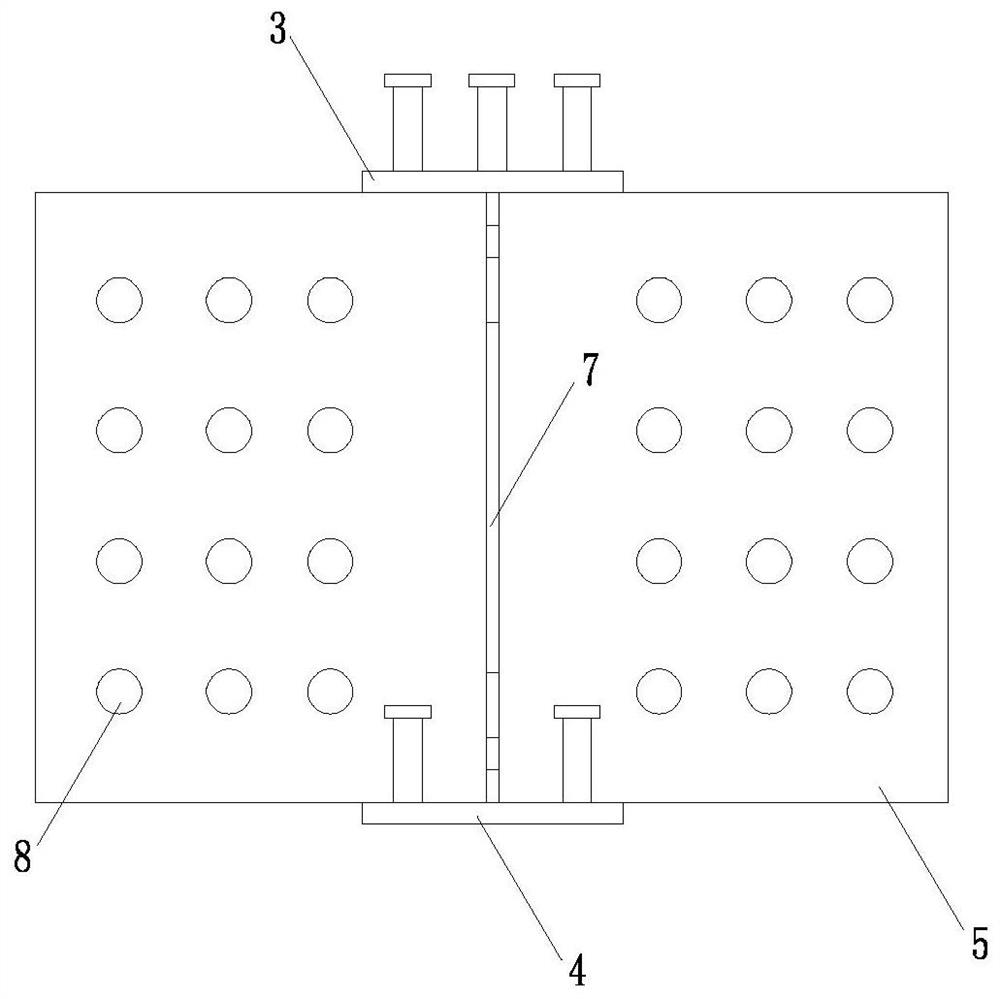

[0024] Please check Figure 1 to Figure 4 , the joint structure of integral abutment and steel girder, which includes an abutment 1 and a steel girder 2, one end of the steel girder 2 is embedded in the abutment 1, and the steel girder 2 is made of section steel, including the upper Wing plate 3, lower wing plate 4 and web 7 connecting (specifically welding) upper and lower wing plates 3, 4, said web plate 7 is perpendicular to upper and lower wing plates 3, 4 and is located on upper and lower wing plates 3 , 4 on the longitudinal symmetrical center plane, the upper and lower wing plates 3, 4 and the web 7 form an I-shaped steel structure with a cross-section in the shape of "I".

[0025] The interface between the abutment 1 and the steel girder 2 is provided with a pressure bearing plate 5 connecting (specifically welded) the upper and lower wings 3, 4 and the web 7, and the pressure bearing plate 5 is attached to the bridge in parallel. The interface between platform 1 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com