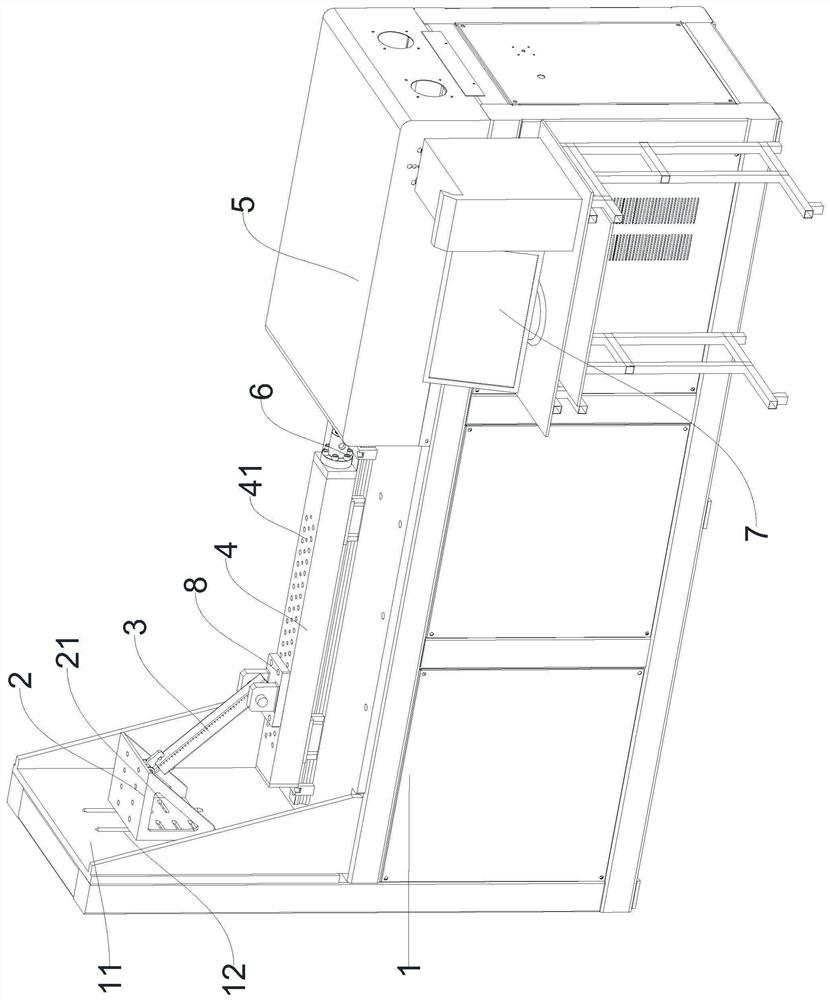

Anti-seismic performance testing equipment and method for anti-seismic support hanger component and inclined strut assembly

A technology of anti-seismic performance and testing equipment, which is applied in the direction of machine/structural component testing, vibration testing, measuring devices, etc., and can solve problems such as difficult customer scheme design, inability to obtain component seismic performance, and inconsistent test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

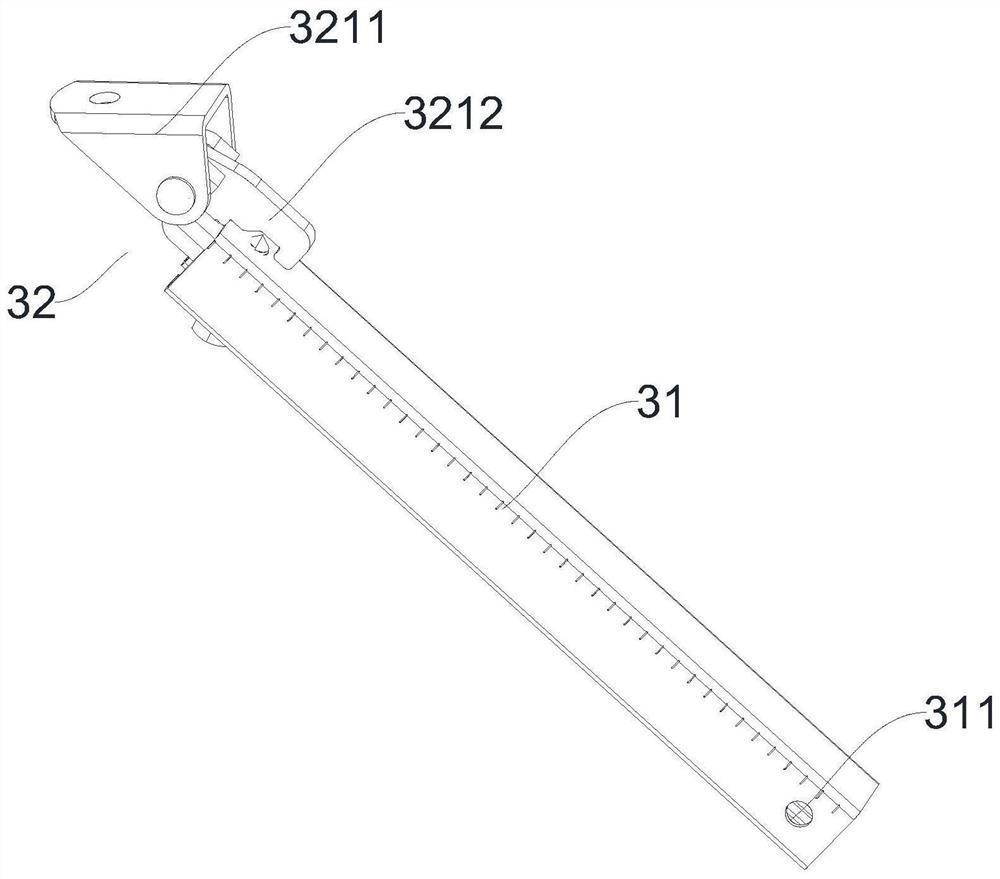

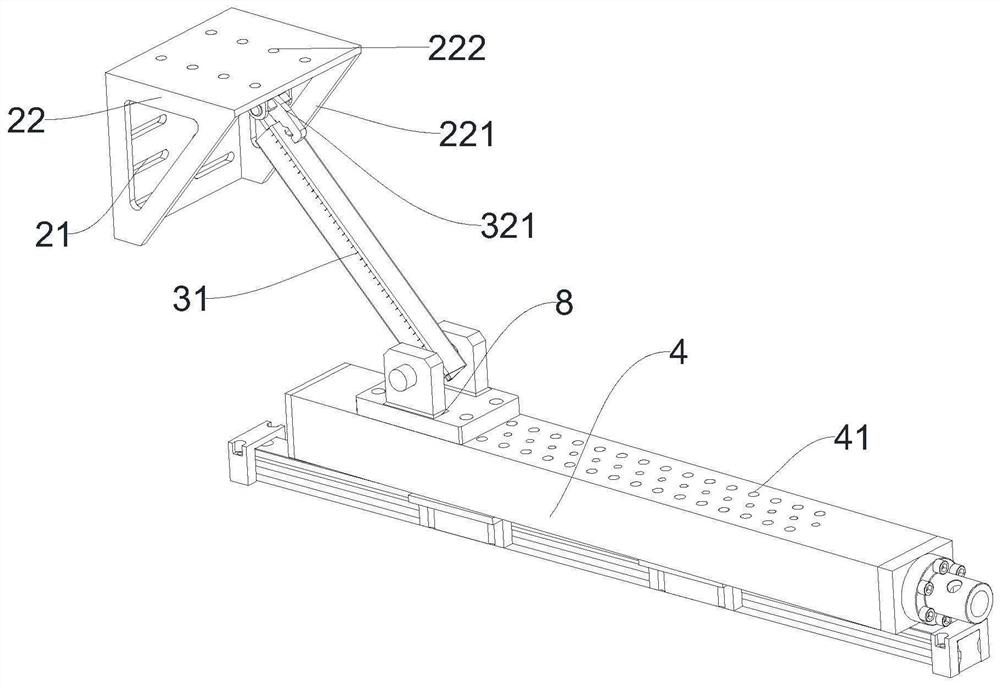

[0123] like figure 2 , image 3 As shown, the connector 32 is a building structure connector 321, the building structure connector 321 includes a fixed part 3211 and a movable part 3212, the fixed part 3211 and the movable part 3212 are hinged, and one end of the movable part 3212 is provided with a clip, and the movable part 3212 passes through The clip part is fixedly connected with one end of the anti-seismic brace 31, and is connected through bolt reinforcement. The other end of the anti-seismic brace 31 is provided with a connecting hole 311, through which the anti-seismic brace 31 is fixedly connected with the test equipment. The diameter of the connection hole 311 is 12 mm.

[0124] The positioning piece 2 is an angle steel 22 , triangular supports 221 are arranged on both sides of the angle steel 22 , and several positioning holes 222 are arranged on the upper surface of the angle steel 22 . The fixing part 3211 on the building structure connecting part 321 is alig...

Embodiment 2

[0129] like Figure 4 , Figure 5 As shown, the DUT 3 includes a pipe connection fixture 323 and an anti-seismic brace 31 , and the pipe connection fixture 323 is fixedly connected to one end of the anti-seismic brace 31 through a connecting member 3231 . One end of the connecting member 3231 is fixedly connected with the pipeline connecting fixture 323 by bolts, and the other end of the connecting member 3231 is provided with a clamp, through which the connecting member 3231 is fixedly connected with one end of the anti-seismic brace 31 and reinforced by bolts. The other end of the anti-seismic brace 31 is provided with a connecting hole 311, through which the anti-seismic brace 31 is fixedly connected with the test equipment. The diameter of the connection hole 311 is 12 mm.

[0130] The positioning part 2 includes a positioning base 231 and a connecting pipe fitting 232. The connecting pipe fitting 232 is fixed between the side walls at both ends of the positioning base 2...

Embodiment 3

[0134] Such as Image 6 , Figure 7 As shown, the test piece 3 includes a steel structure fixture 322, an anti-seismic brace 31 and a fixing part 3211. One end of the steel structure fixture 322 and the fixing part 3211 is fixedly connected by a bolt, and the other end of the fixing part 3211 is connected to the anti-seismic brace 31 through a bolt. One end is fixedly connected, so that the fixing part 3211 is hinged with the anti-seismic brace 31. The other end of the anti-seismic brace 31 is provided with a connecting hole 311, through which the anti-seismic brace 31 is fixedly connected with the test equipment. The diameter of the connection hole 311 is 12 mm.

[0135] The positioning part 2 is a steel plate 24 provided with wing plates at the upper and lower ends, and the steel structure clamp 322 clamps one of the wing plates, so that the positioning part 2 is fixedly connected with the connecting part 32 .

[0136] The fixed guide rail 4 is provided with a bolt fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com