Hydrogen and humidity integrated sensor, hydrogen humidity detection device based on self-reference technology and application

A humidity sensor and sensor technology, which is used in measuring devices, converting sensor outputs, and using optical devices to transmit sensing components, etc., can solve the problems of low device integration, large equipment volume and high cost, and achieve good light source fluctuation and practicality. Strong and resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0034] The present embodiment is the further optimization carried out on the basis of embodiment 1, and it is specifically as follows:

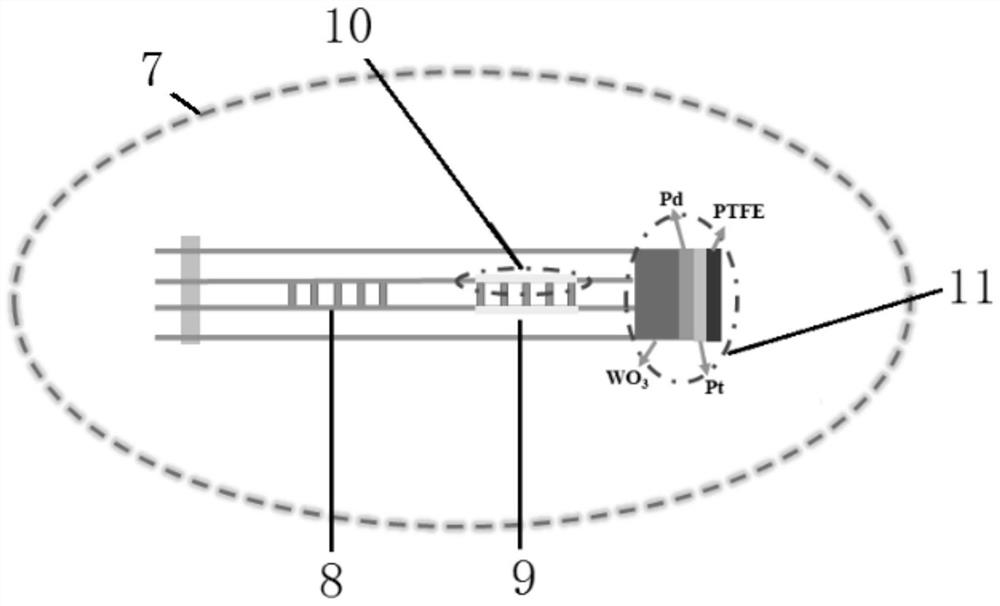

[0035] Such as figure 1 As shown, the hydrogen sensitive film 11 is made of WO 3 - Composition of three-layer composite film composed of four materials: PdPt-PTFE.

[0036] Going a step further: WO 3 Layer as a hydrogen sensitive layer, its thickness is 10nm ~ 1500nm;

[0037] The PdPt layer is used as a catalytic layer, the atomic ratio of Pd and Pt in this layer is 1: (1~20), and the thickness is 20-750nm;

[0038] The PTFE layer is used as a protective layer, and its thickness is 20nm-750nm.

Embodiment 3

[0040] The present embodiment is the further optimization carried out on the basis of embodiment 1 or 2, and it is specifically as follows:

[0041] Such as figure 1 As shown, the humidity sensitive film 10 is composed of polyimide film, and its thickness is 10 μm˜150 μm.

Embodiment 4

[0043] The present embodiment is the further optimization carried out on the basis of embodiment 1 or 2 or 3, and it is specifically as follows:

[0044] Such as figure 1 As shown, the center wavelength difference between the reference grating 8 and the sensing grating 9 is 5-20 nm, the reference grating 8 is a long-wavelength grating, and the sensing grating 9 is a short-wavelength grating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com