Composite-structure Co-Nx/C monatomic catalyst, preparation method thereof and fuel cell

A composite structure and catalyst technology, applied in battery electrodes, structural parts, circuits, etc., can solve the problems of unsatisfactory electrochemical energy conversion efficiency, low catalytic single-atom Co loading, unsatisfactory catalytic activity, etc., to achieve rich catalytic reactions Active sites, beneficial effects on stability, structure and performance stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

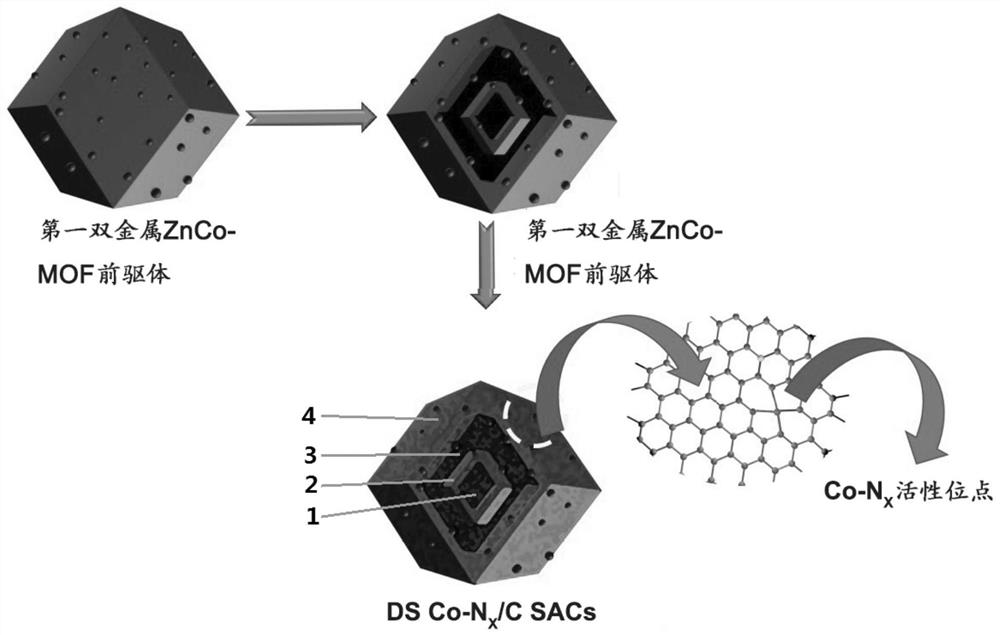

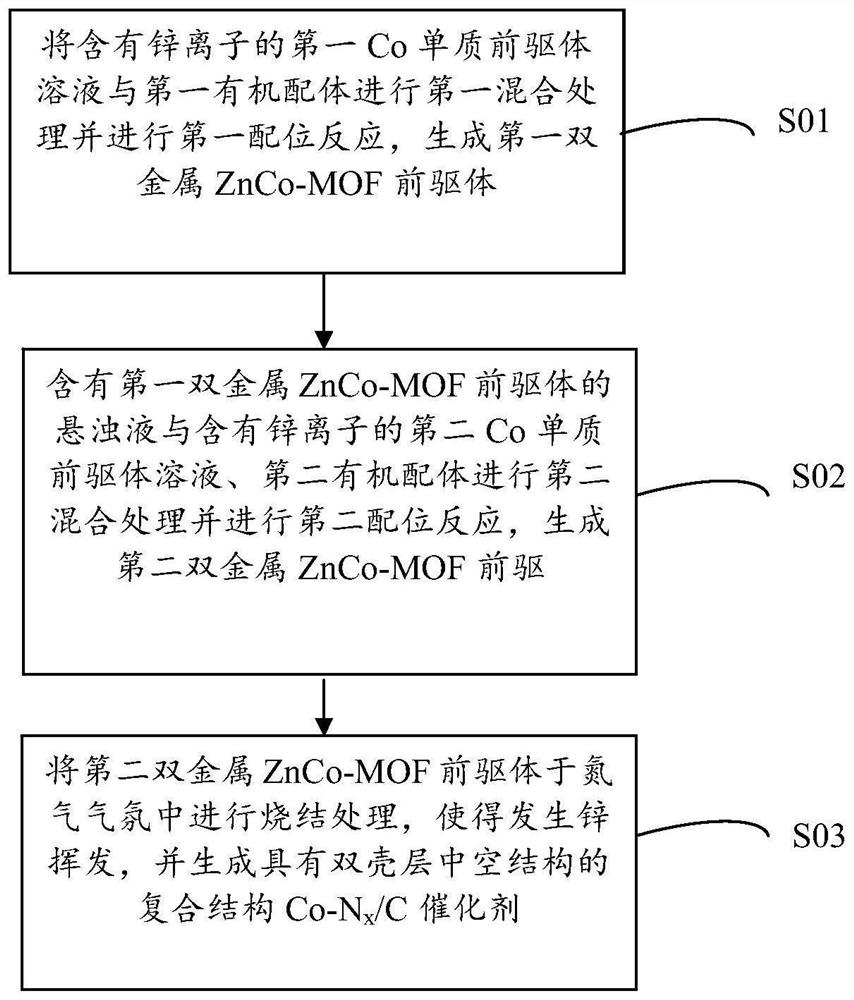

[0047] Correspondingly, the embodiment of the present invention also provides the above-mentioned composite structure Co-N x The preparation method of / C single-atom catalyst. The composite structure Co-N x The preparation design route of / C single-atom catalyst is as follows figure 2 , according to this design route, the composite structure Co-N x The technological process of / C single-atom catalyst preparation method is as image 3 shown, combined with figure 1 , which includes the following steps:

[0048] Step S01: performing a first mixing treatment with a first Co elemental precursor solution containing zinc ions and a first organic ligand and performing a first coordination reaction to generate a first bimetallic ZnCo-MOF precursor;

[0049] Step S02: performing a second mixing treatment on the suspension containing the first bimetallic ZnCo-MOF precursor, a second Co elemental precursor solution containing zinc ions, and a second organic ligand, and performing a ...

Embodiment 1

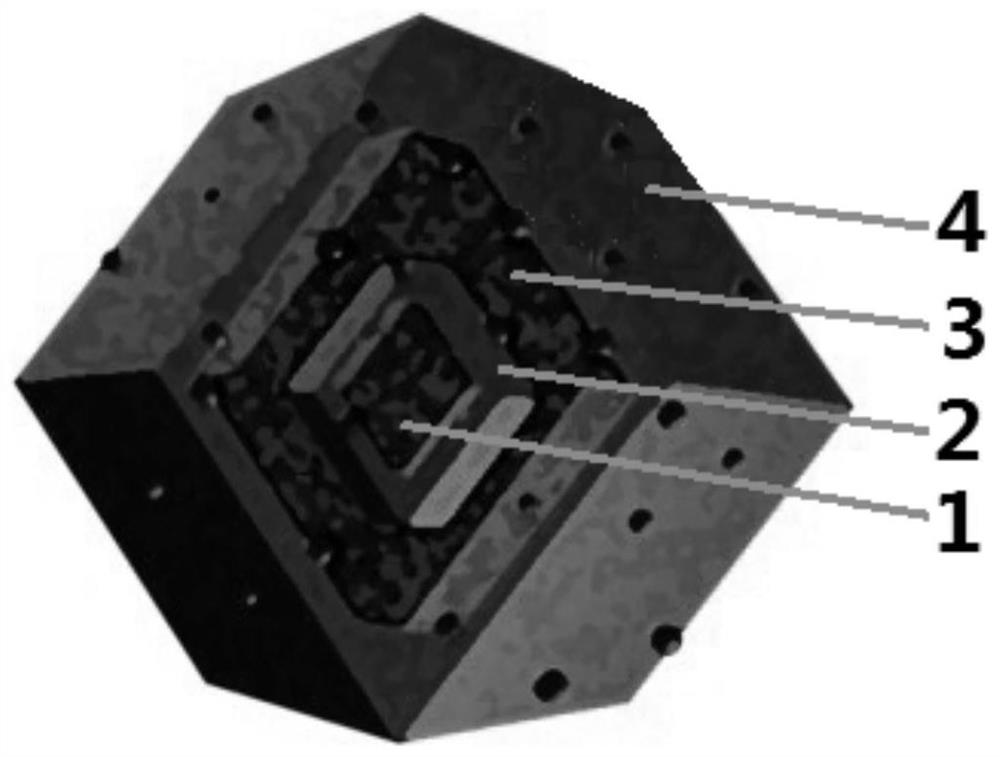

[0065] This embodiment provides a composite structure Co-N x / C single atom catalyst and its preparation method. The composite structure Co-N x The structure of / C single-atom catalyst is as follows figure 1 As shown, it is a double-shell hollow structure, including an inner shell 2 and an outer shell 4 covering the inner shell 2, and the inner shell 2 is covered to form a cavity 1, and the inner shell 2 and the outer shell 4 There is a gap 3 between them; wherein, the materials of the inner shell layer 2 and the outer shell layer 4 both contain Co-N x / C single atom catalyst material. Based on the composite structure Co-N x The structure of / C single-atom catalyst, the composite structure Co-N of the embodiment of the present invention x / C single-atom catalyst is denoted as DS·Co-N x / C SACs catalyst.

[0066] DS·Co-N x The preparation method of / C SACs catalyst comprises the following specific steps:

[0067] S1: Co(NO 3 ) 2 ·6H 2 O 1.8mmol, Zn(NO 3 ) 2 ·6H 2...

Embodiment 2

[0072] S1: Co(NO 3 ) 2 ·6H 2 O 1.8mmol, Zn(NO 3 ) 2 ·6H 2 O 1.8mmol was dissolved in 15mL of methanol, and stirred to form a clear and transparent solution A; about 10.8mmol of 2-methylimidazole was dissolved in 15mL of methanol to form a clear and transparent solution B;

[0073] S2: After mixing solution A and solution B in step S1, stir at room temperature for 12 hours, and perform a coordination reaction; after the reaction, add a certain amount of methanol in sequence, filter, wash, and dry to obtain a bimetallic ZnCo-MOF precursor body; get 50mg of ZnCo-MOF precursor, dispersed in 30mL of methanol to form ZnCo-MOF precursor suspension;

[0074] S3: Co(NO 3 ) 2 ·6H 2 O 0.03mmol, Zn(NO 3 ) 2 ·6H 2 O 0.26mmol, dissolved in 10mL of methanol to form a clear and transparent solution C; about 0.0985g (1.2mmol) of 2-methylimidazole was dissolved in 10mL of methanol to form a clear and transparent solution D, after mixing solution C and solution D, Then add it to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com