Splicing type binding post assembly

A technology of terminals and components, which is applied in the direction of contacting parts, devices for joining/disconnecting connecting parts, parts of connecting devices, etc., can solve the problems of difficulty in adapting to changing optimization requirements, poor adaptability, poor continuity, and high processing costs. Achieve the effects of good structural strength and electrical conductivity, strong adaptability and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention will be further described below with reference to the accompanying drawings, but it is not understood to the present invention, and without departing from the above technical ideology without departing from the present invention, there is a general technical knowledge and Various modifications, replacements, and modifications made by the usual means are included within the scope of the invention.

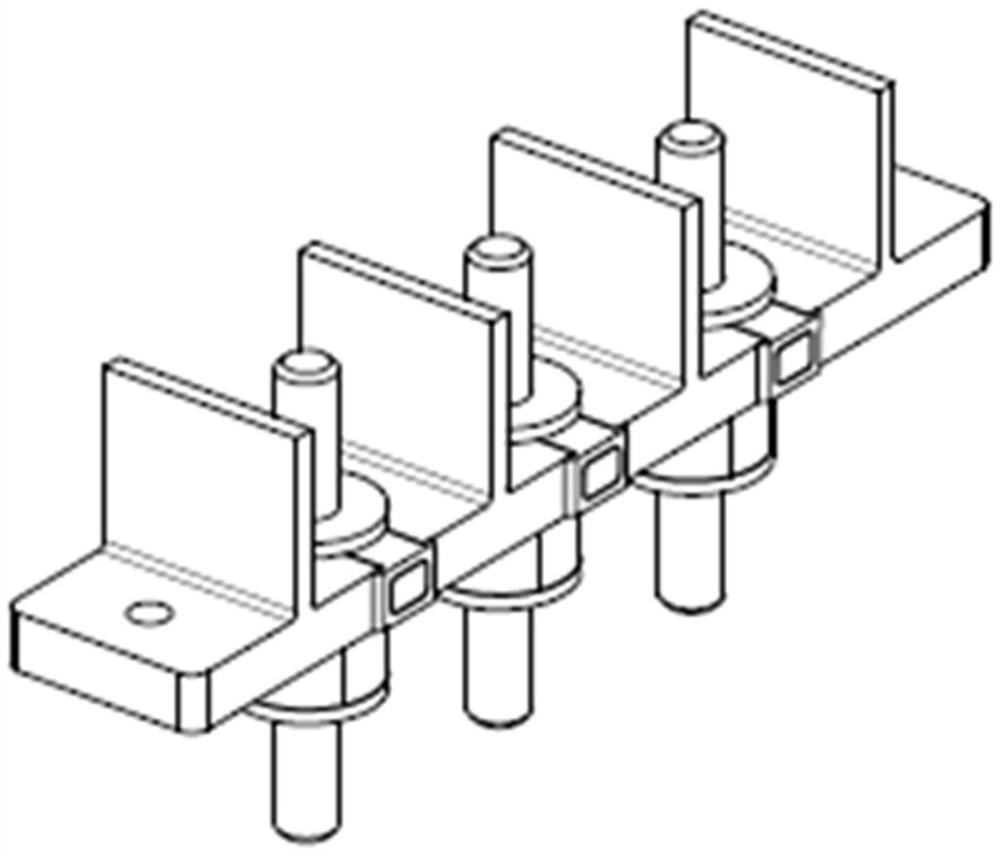

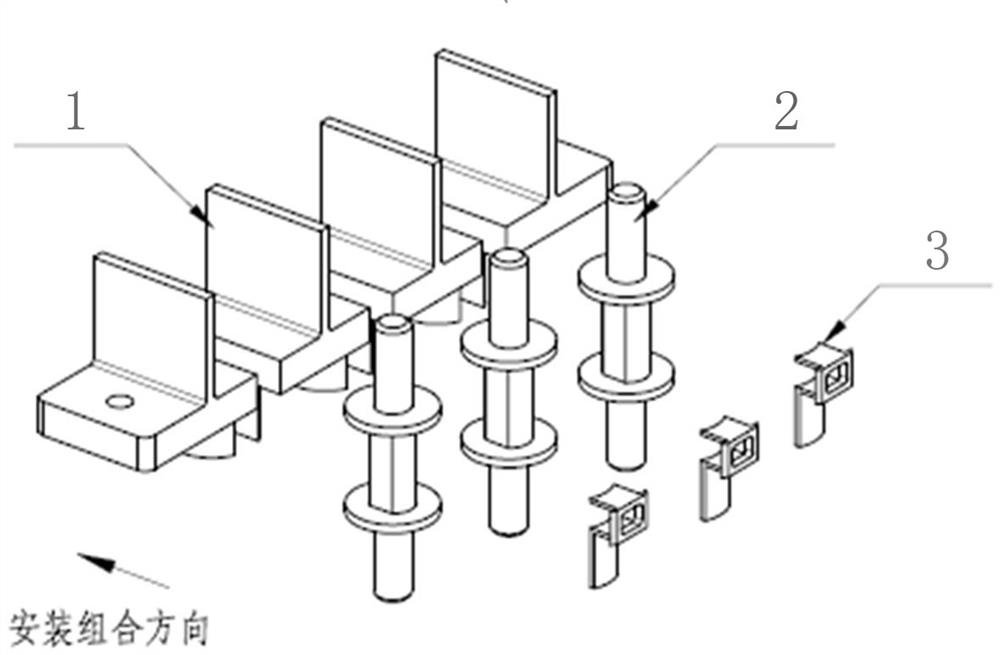

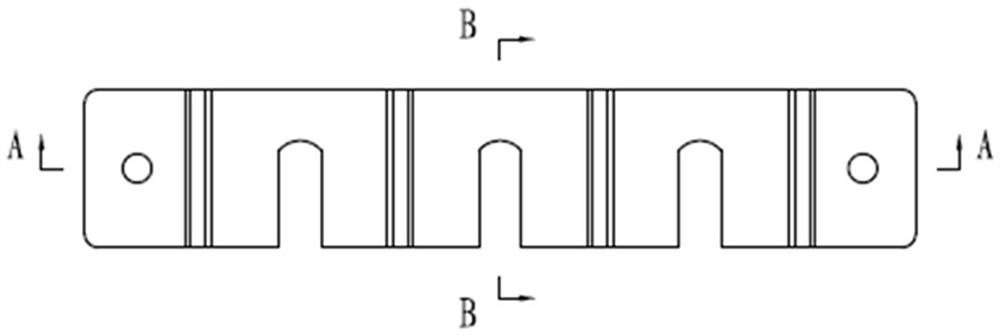

[0020]Such asfigure 1 As shown, the splicing type terminal assembly is composed of a terminal block 1, a terminal 2, and a fixed block 3, and a milling bolt is opened on the terminal block, and the intermediate portion of the terminal 2 is bonded to the epoxy adhesive. In the milling bracket, the fixing block 3 is bonded to the terminal 2 by epoxy gum.

[0021]The present invention mainly passes through the machining and mounting of the machine, wherein the terminal 2 is formed by the combination of the vehicle milling. After the processing is completed, different su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com