Process for producing milk and milk-related products with extended shelf life

A related product and shelf-life technology, which is applied in the field of milk and milk-related products with a shelf life, can solve the problems of complex process, increased floor space of microfiltration equipment, and increased risk of failure, etc., to achieve the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

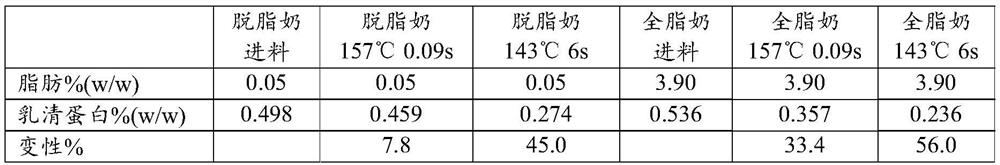

[0042] The whole milk is separated into a cream fraction and a skim milk fraction by centrifugation. The skim milk portion was preheated at 72°C for 15 seconds, ie pasteurized, then heated to 157°C for 0.09 seconds and rapidly cooled to 70°C or lower. For comparison purposes, a portion of the skim milk fraction was also treated after preheating by using the standard instant injection (UHT) process of heating to 143°C for 6 seconds.

[0043] Whole milk is similarly treated as shown in the table below:

[0044] Table 1: All figures are in % by weight

[0045]

[0046] The data in the table shows that only 7.8% by weight of whey protein was denatured by the method of the present invention. In contrast, 33.4% by weight of whey protein in whole milk was denatured, suggesting that fat content plays a crucial role in the denaturation of whey protein in milk and milk-derived products.

[0047] The data also indicate that temperature and time are important for whey protein denatu...

Embodiment 2

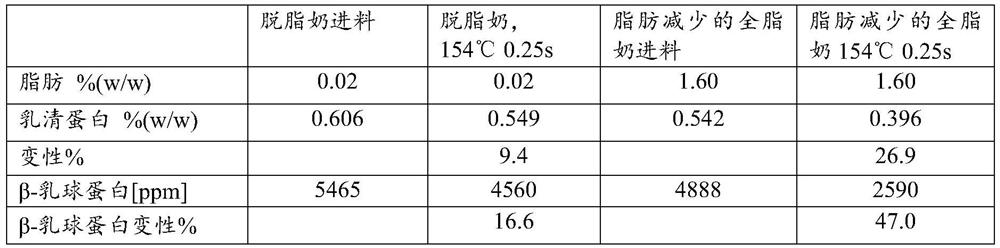

[0050] The whole milk is separated into a cream fraction and a skim milk fraction by centrifugation. The skim milk portion was preheated at 72°C for 15 seconds, ie pasteurized, then heated to 154°C for 0.250 seconds and rapidly cooled to 70°C or lower. For comparison purposes, a portion of the skim milk fraction was also treated after preheating by using the standard instant injection (UHT) process of heating to 143°C for 6 seconds.

[0051] As a control experiment, milk with a reduced fat content of 1.6% (by weight) was treated in a similar manner as shown in the following table:

[0052] Table 2

[0053]

[0054] The data in Table 2 show that only 16.6% by weight of beta-lactoglobulin was denatured by the method of the invention. In contrast, 47.0% by weight of β-lactoglobulin was denatured in reduced-fat whole milk, indicating that fat Quantity plays a crucial role in the denaturation of β-lactoglobulin and whey protein.

[0055]From the data in Table 2, the denatura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com