Green feed smashing device

A technology of green fodder and rolling device, which is applied in cutting equipment, agricultural machinery and implements, etc. It can solve the problems of difficult control of green fodder size, change of cutting track, poor rigidity of cutting knife, etc., and achieve good cutting effect and small swing , to avoid the effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

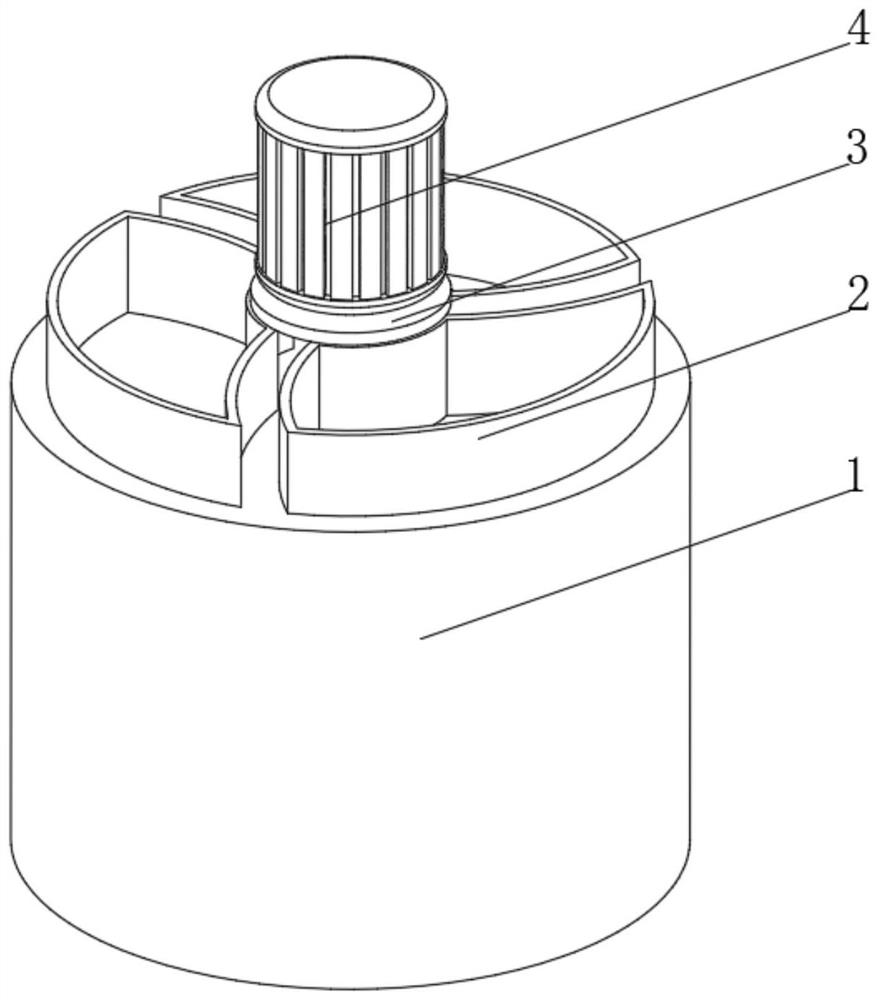

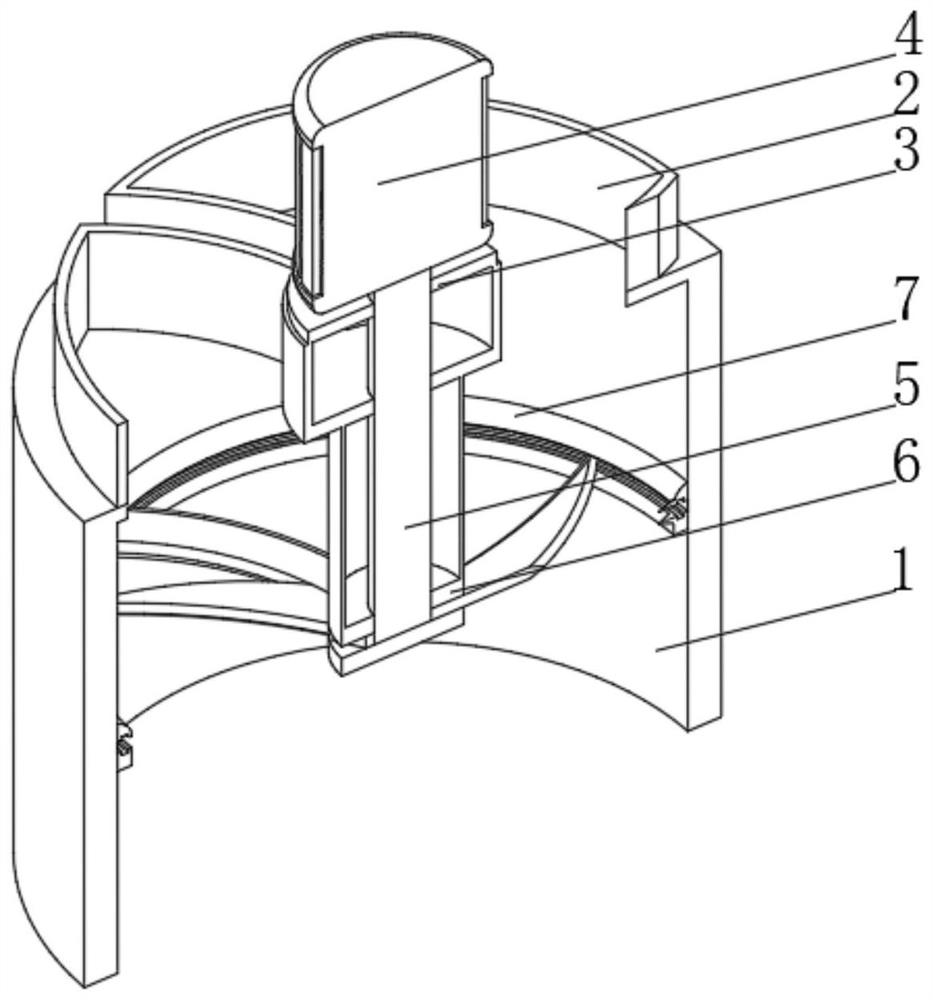

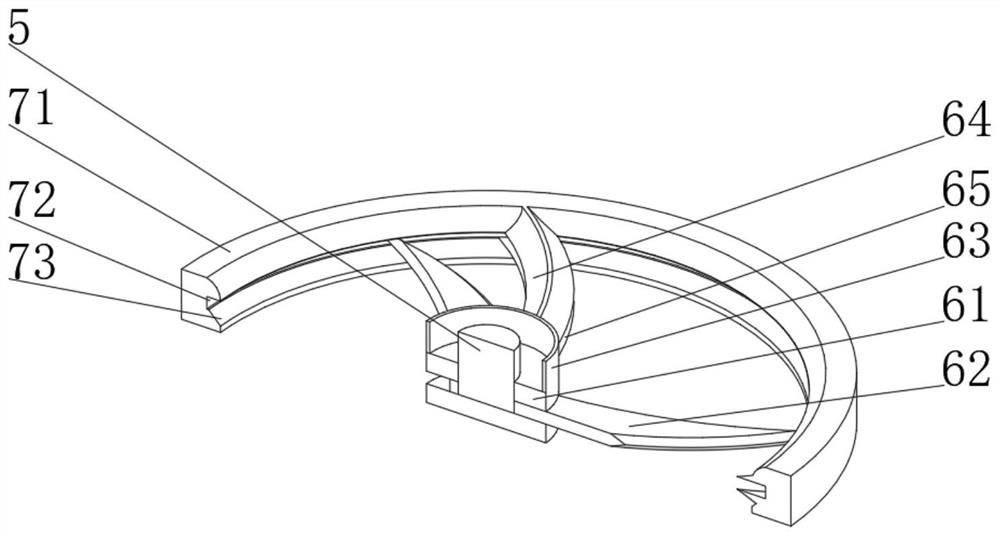

[0032] see Figure 1-3 , the present invention provides a technical solution: a green fodder crushing device, comprising a crushing barrel 1, the top of the crushing barrel 1 is provided with a feed port 2, the center of the top of the crushing barrel 1 is fixedly connected with a motor support seat 3, and the motor The top of the support base 3 is fixedly connected with a drive motor 4, the drive shaft of the drive motor 4 runs through the motor support base 3 and is fixedly connected with a rotation shaft 5, and the end of the rotation shaft 5 away from the drive motor 4 extends to the inside of the crushing bucket 1 and is fixedly connected with a Breaking device 6, the part corresponding to the inner wall of breaking barrel 1 and breaking device 6 is fixedly connected with limiter 7, and breaking device 6 includes a rotating seat 61, and the inner wall of rotating seat 61 is rotatably connected with a cutting knife 62, and the top of rotating seat 61 is fixed Connected wit...

Embodiment 2

[0035] see Figure 1-5On the basis of Embodiment 1, the present invention provides a technical solution: the cutting knife 62 includes a cutting knife body 621, the top of the cutting knife body 621 is provided with an arc-shaped chute 622, and one end of the inner wall of the arc-shaped chute 622 is fixedly connected with a return spring 623, the part of the return spring 623 away from the inner wall of the arc-shaped chute 622 is fixedly connected to the limit slider 624, and both ends of the limit slider 624 extend to the outside of the arc-shaped chute 622 and are fixedly connected with a rolling device 625, and the rolling device 625 It includes a rotating disk 6251, a ball groove 6252 is opened on the outside of the rotating disk 6251, a ball group 6253 is slidably connected to the inner wall of the ball groove 6252, an outer fixed ring 6254 is slidably connected to the outer side of the ball group 6253, and an arc is slidably connected to the outer side of the outer fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com