Film full-open type arch-shaped film greenhouse

A film and greenhouse technology, applied in the field of film full-open arched film greenhouses, can solve the problems of adverse effects on crop growth, waste of high-quality land resources, and difficulty in cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

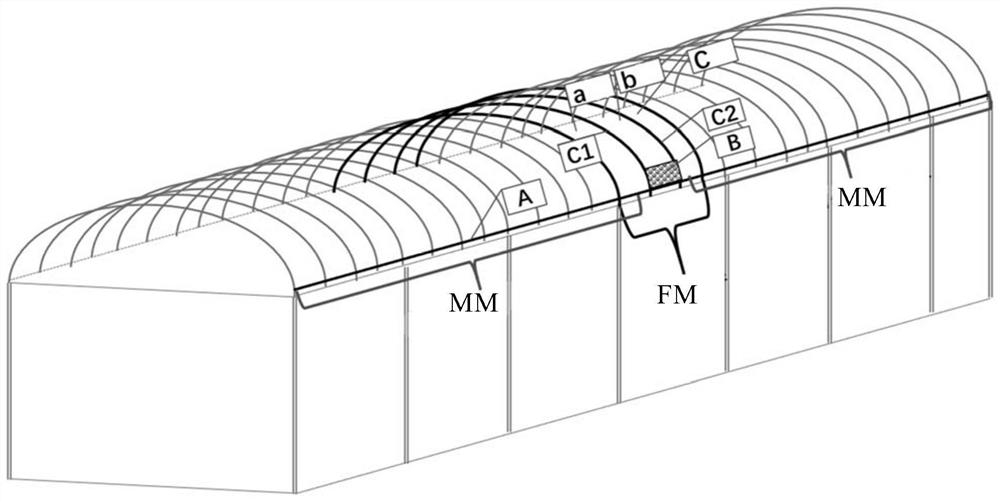

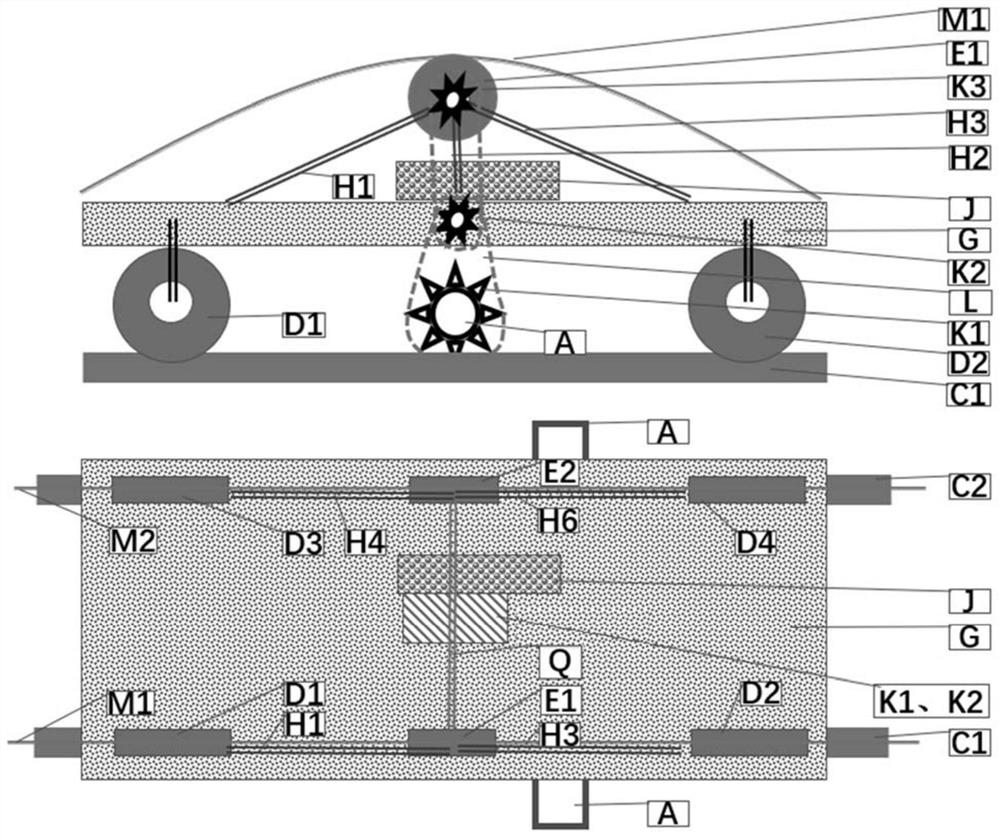

[0073] A 5-span standard 8432-type greenhouse (single-span length 40m, span 8m), shed area 1600m 2 . The greenhouse construction is carried out according to the conventional greenhouse specifications, and the distance between arches and stems is 1.33 meters. The conventional greenhouse can be changed into a fully open plastic greenhouse by adding the following projects:

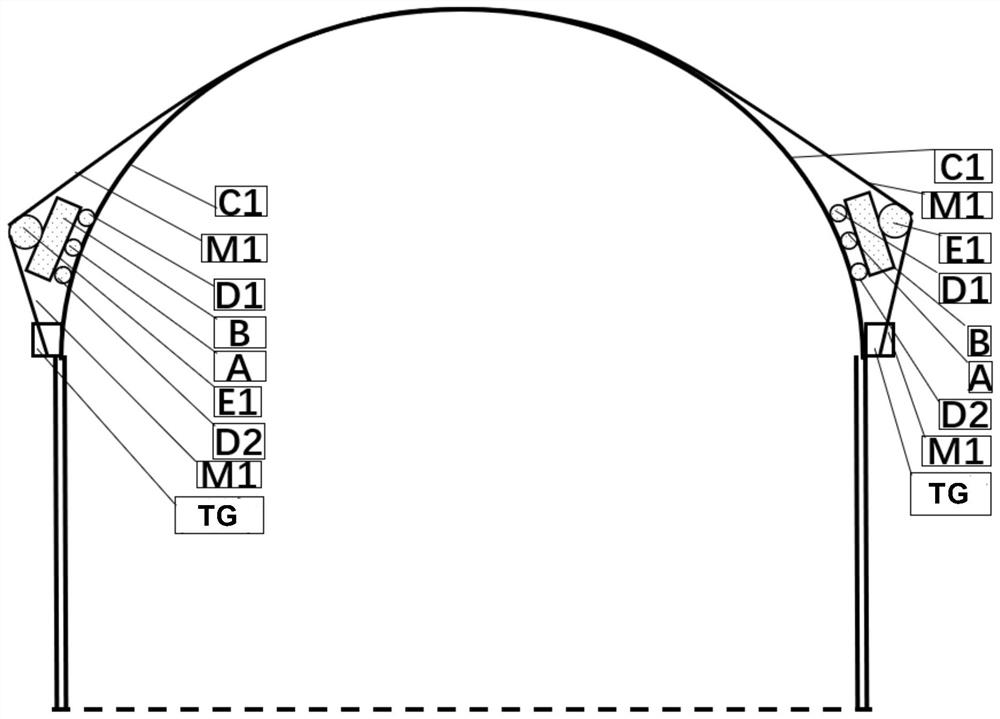

[0074] 1) Move up the lamination grooves of the skylights on both sides of the original arched shed near the gutter to a distance of 50cm from the vault.

[0075] 2) From north to south, the 1st-2nd, 14th-17th, and 30th-31st arches are all equipped with film-pressing grooves and plastic films, forming three covered and fixed plastic film areas. The same addition works are done for each span of the vault.

[0076] 3) Install two hooks at the bottom of the gutter directly below the sides of the 15th and 16th arches. The same addition works are done for each span of the vault.

[0077] 4) Take the 15th and ...

Embodiment 2

[0082] The area of a shed is 160000m2 2 Greenhouse (north-south building, 400m long from north to south, 4m bays from north to south, 100 bays, 1.33m distance between arches, 400m long from east to west, 8m single arch span from east to west, 50 spans in total), the construction is carried out according to the conventional greenhouse specifications, and the following projects are added :

[0083] 1) Move the original skylight lamination groove of each span of the vault to 50cm away from the vault.

[0084] 2) From north to south, No. 1-2, No. 14-17, No. 30-31, No. 44-47, No. 60-61, No. 74-77, No. 90-91, No. 104-107, No. 120-121 , No. 134-137, No. 150-151, No. 164-167, No. 180-181, No. 194-197, No. 210-211, No. 224-227, No. 240-241, No. 254-257, No. 270-271 , No. 284-287, and No. 299-300 arches are all equipped with laminating grooves and plastic films. The same addition works are done for each span of the vault.

[0085] 3) The 15th and 16th, 45th and 46th, 75th and 76th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com