Full-automatic welding device and method for steel pipe furniture

A fully automatic welding and transmission technology, applied in the field of furniture manufacturing, can solve the problems of reducing labor costs, low production efficiency, disadvantages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

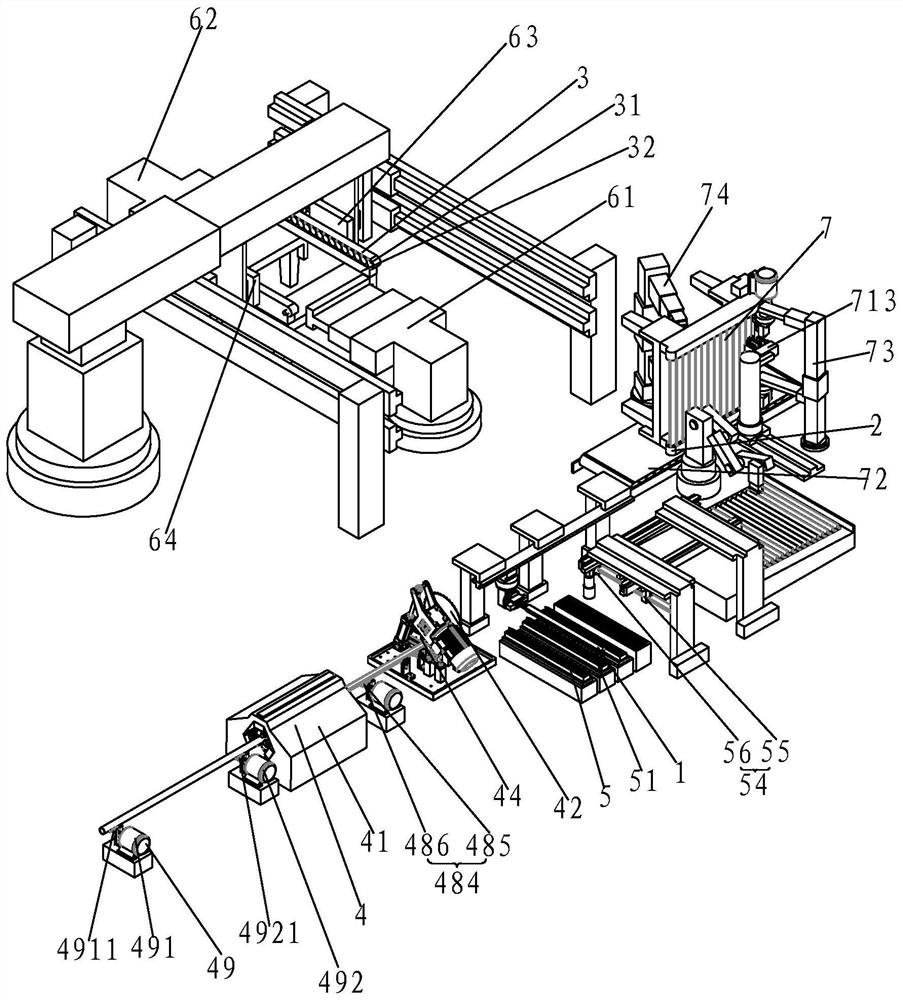

[0102] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

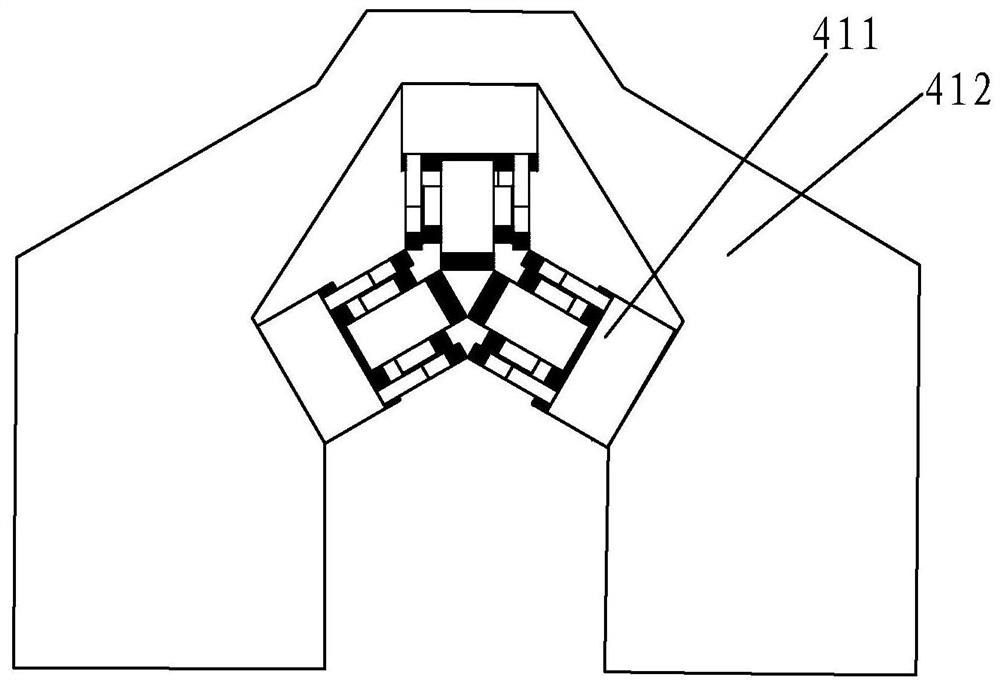

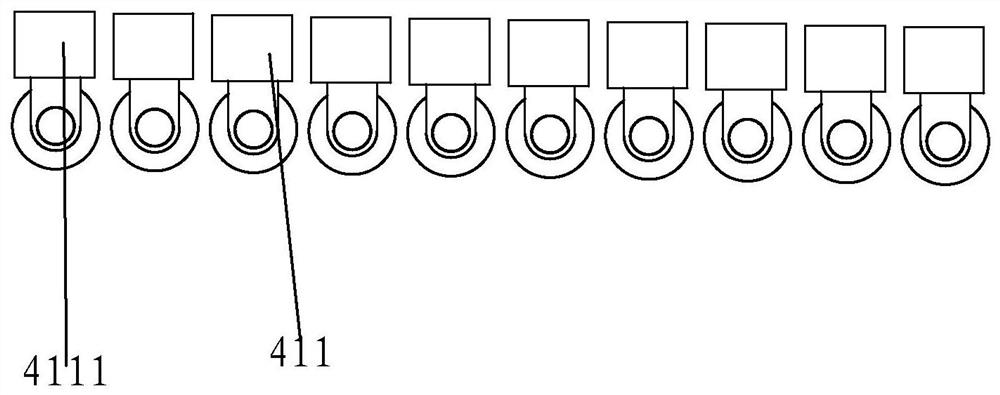

[0103] Such as Figure 1 to Figure 7 As shown, a fully automatic welding device for steel pipe furniture of the present invention includes a forming mechanism 4 for processing a triangular steel pipe 1, a painting device 5 for painting the outer surface of the triangular steel pipe 1, and a paint coating device 5 for both ends of the triangular steel pipe 1. Grinding mechanism 54 for grinding, transmission device for changing color of triangular steel pipe 1, first assembly mechanism for assembling transmission device into table main body, and second assembly mechanism 7 for connecting triangular steel pipe 1 to transmission device.

[0104] In this way, after the circular strip pipe is gradually extruded into a triangular strip pipe by the forming device 41, the cutting device 42 cuts the triangular strip pipe into equally divided t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com