Accurate pug batching system for wine jars and pug production method

A batching system and production method technology, which is applied in the field of ceramic production, can solve the problems of low batching accuracy and inaccurate mud-to-material formula ratio, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a precise batching system for mud for wine jars;

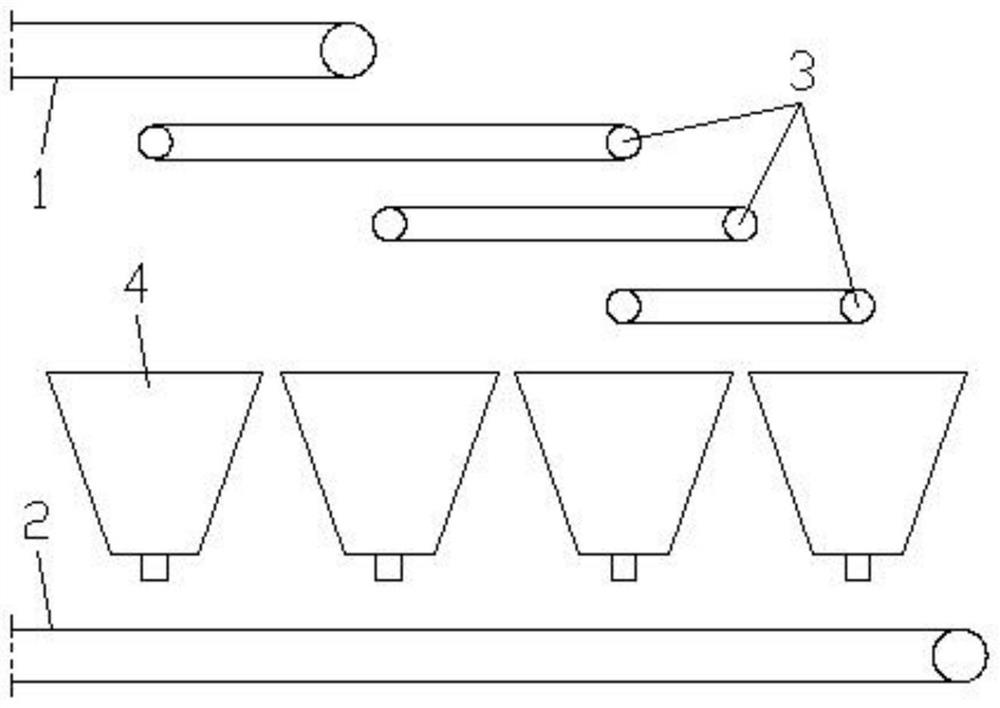

[0033] Such as figure 1 As shown, the precise batching system for mud for wine jars in this embodiment includes an incoming material belt 1 and a mixing belt 2. Several layers of conveyor belts 3 are arranged below the incoming material belt 1, and the conveyor belts 3 of adjacent layers are spaced in parallel. It is set and the ends are partially overlapped. Several weighing hoppers 4 are arranged under the conveyor belt 3 on the bottom layer. Each weighing hopper 4 has its own weight sensor. All weighing hoppers 4 are arranged in rows and evenly spaced, and each The center of each weighing hopper 4 is located directly below the end of the conveyor belt 3, and the bottom of each weighing hopper 4 is provided with a discharge port, and the discharge port is electronically controlled to open and close, and the mixing belt 2 is located below the outlets of all weighing hoppers 4 .

[0034] When ...

Embodiment 2

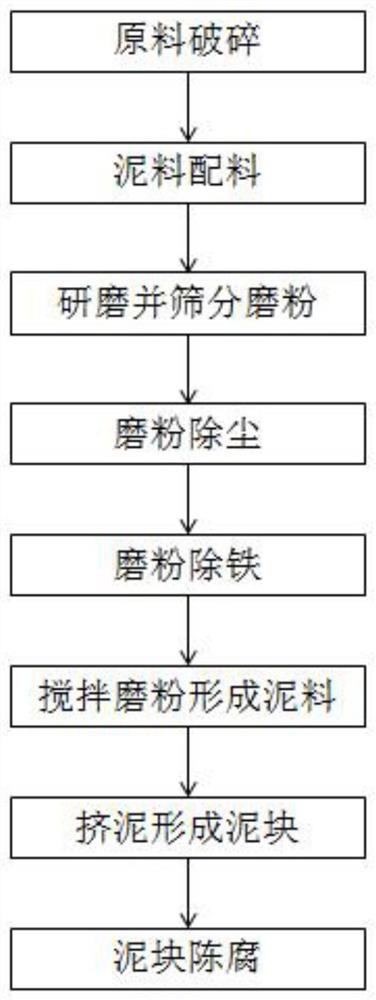

[0040] Such as figure 2 As shown, the present embodiment provides a mud production method, comprising the following steps:

[0041] Step 1. Crushing: crushing various raw materials after mining;

[0042] Step 2, batching: the various raw materials after crushing are batched by the precise batching system for mud for wine jars described in Example 1 to form a mixture;

[0043] Step 3. Grinding: Grinding the mixed material after batching, and sifting out the grinding powder that meets the particle size requirements of the mud;

[0044]Step 4. Stirring: Send the milled powder into the mixer for adding water and stirring to form mud;

[0045] Step 5. Squeeze mud: Send the mud material formed by stirring into the vacuum mud extruder for extrusion to form mud block;

[0046] Step 6, stale: place the mud block in a constant temperature and humidity environment for 10-12 days.

[0047] This method first crushes various raw materials after mining to facilitate the subsequent batch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com