Industrial wastewater treatment device with self-cleaning function

A technology of industrial waste water and treatment equipment, applied in the field of sewage treatment, can solve problems such as poor use effect, influence on filtration effect, accumulation of impurities, etc., and achieve the effect of improving use effect and simple and convenient dosing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

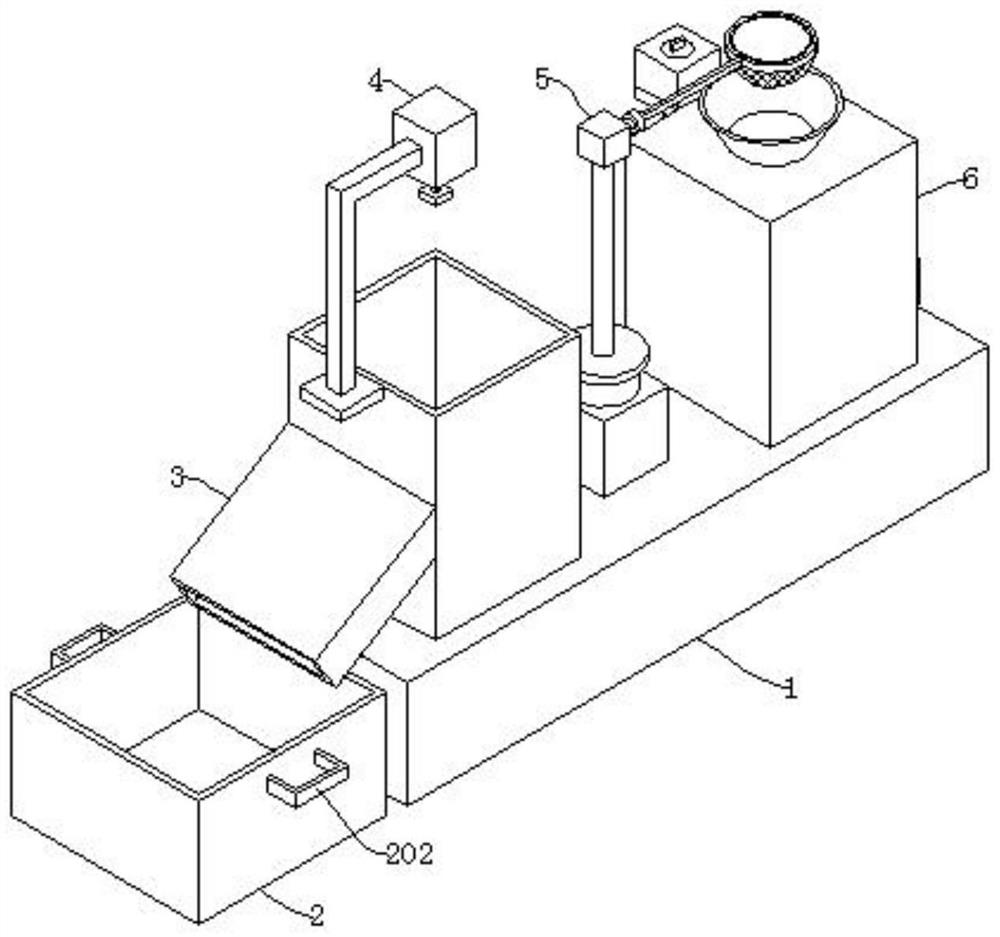

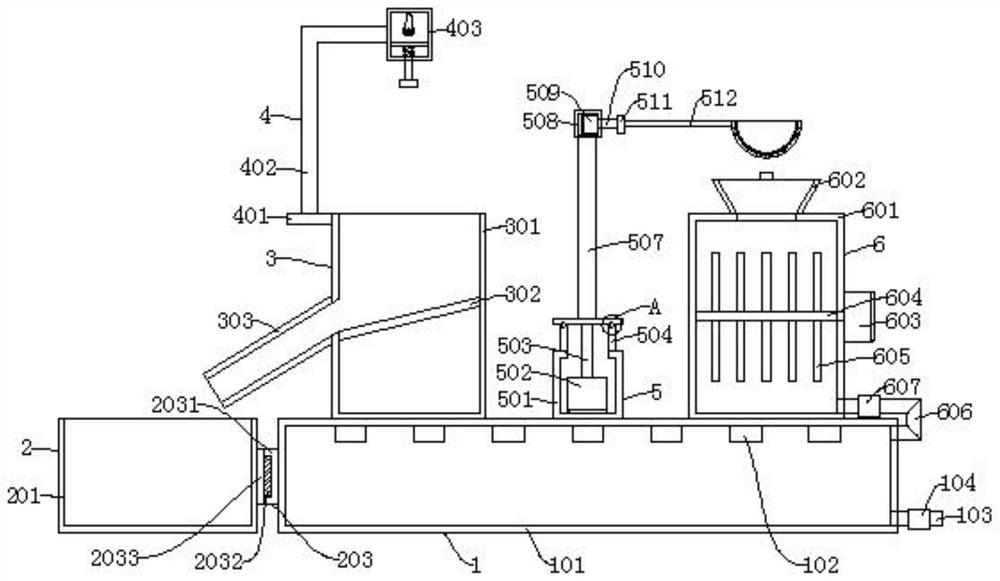

[0041] Such as figure 1 , image 3 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, an industrial wastewater treatment device with self-cleaning function includes a disinfection mechanism 1, a collection mechanism 2 for collecting impurities, and a conveying mechanism 3. The collection mechanism 2 is installed on the side of the disinfection mechanism 1, and the conveying mechanism is installed above the disinfection mechanism 1. The mechanism 3 also includes a knocking mechanism 4, a filtering mechanism 5, and a neutralizing mechanism 6. The knocking mechanism 4 is fixed on the conveying mechanism 3, the filtering mechanism 5 is arranged on one side of the conveying mechanism 3, and the neutralizing mechanism 6 is arranged on the filtering mechanism 5 A side away from the conveying mechanism 3;

[0042] The knocking mechanism 4 comprises a first fixed plate 401, a bent bar 402, a first protective box 403, a lifting plate 404, a first motor 405, a first rotating ...

Embodiment 2

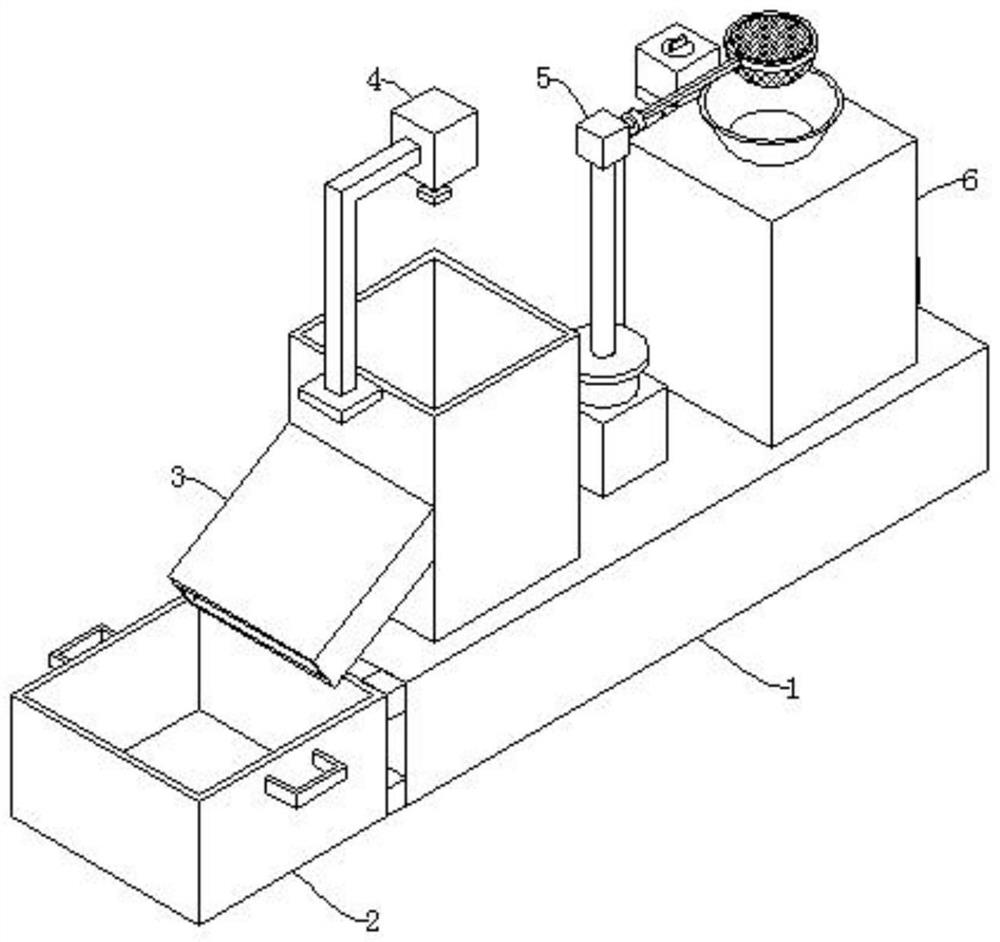

[0048] Such as figure 2 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, the difference between Embodiment 2 and Embodiment 1 is that the installation seat 2031, the first electromagnet 2032, and the adsorption plate 2033 are replaced by the insertion sleeve 2034, the second electromagnet 2035, and the insertion rod 2036, and it is necessary to move the collection box 201 , so that the second electromagnet 2035 is powered off, and the insertion rod 2036 is moved out of the insertion sleeve 2034 to move the collection box 201 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com