Preparation process of porous ceramic

A preparation process and a technology for porous ceramics, applied in the field of ceramics, can solve the problems that porous ceramics are not suitable for the use environment of high air flow, and it is difficult to achieve three-dimensional connectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment provides a preparation process of porous ceramics, which includes:

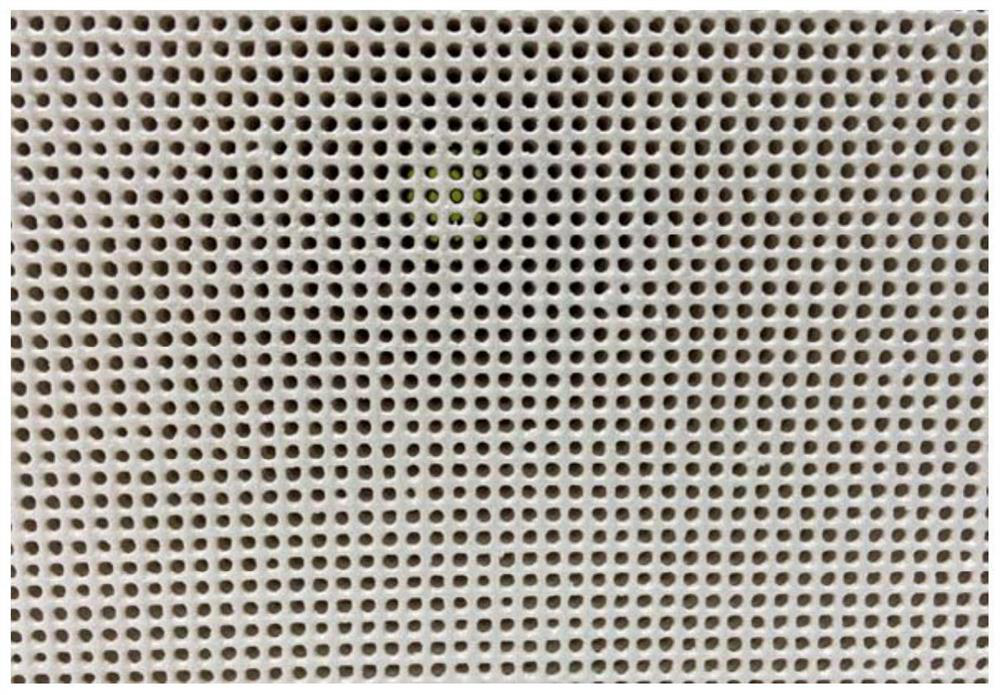

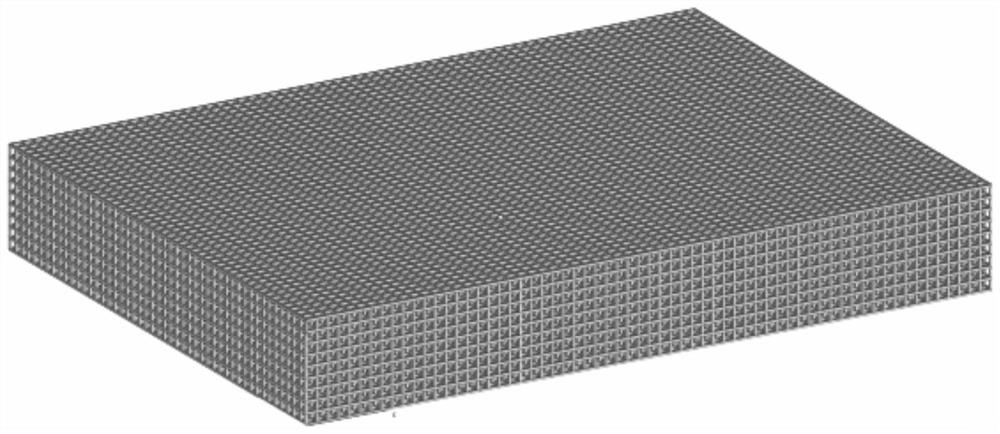

[0042] Design the three-dimensional model of the three-dimensional model material, convert it into USP format and input it into the 3D printer, and then use the resin to print the three-dimensional model material through the 3D printer. The size of the three-dimensional model material is 140mmx290mmx25mm, and the shape of the hole is a square with a side length of 2mm.

[0043] Immerse the printed 3D model material in the aluminum titanate ceramic slurry, take it out and centrifuge to shake off the excess slurry, and use 0.3MPa compressed air to blow the slurry on the surface of the 3D model material evenly, and then place it in a blast drying oven. Dry at 100°C for 30 minutes; repeat the steps of dipping, centrifuging, purging and drying until the volume fraction of the three-dimensional model material reaches 20%. Among them, the amount of aluminum titanate ceramic slurry is de...

Embodiment 2

[0046] The present embodiment provides a preparation process of porous ceramics, which includes:

[0047] Design the three-dimensional model of the three-dimensional model material, convert it into USP format and input it into the 3D printer, and then use the resin to print the three-dimensional model material through the 3D printer. The size of the three-dimensional model material is 140mmx100mmx25mm, and the shape of the hole is a square with a side length of 1.5mm.

[0048] Immerse the printed 3D model material in the aluminum titanate ceramic slurry, take it out and centrifuge to shake off the excess slurry, and use 0.6MPa compressed air to blow the slurry on the surface of the 3D model material evenly, and then place it in a blast drying oven. Dry at 120°C for 30 minutes; repeat the steps of dipping, centrifuging, purging and drying until the volume fraction of the three-dimensional model material reaches 30%. Among them, the amount of aluminum titanate ceramic slurry is ...

Embodiment 3

[0051] This example provides a preparation process of porous ceramics, the preparation steps of which are basically the same as those of Example 1, the only difference being that the pyrolysis process of Example 3 is carried out in an air atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com