Fastener for aviation and preparation method of fastener

A fastener and aviation technology, applied in the field of alloys, can solve the problems that alloys cannot meet the design requirements of fasteners, insufficient corrosion resistance, poor oxidation resistance, etc., achieve good high temperature corrosion resistance, increase stability, The effect of improving the performance of hydrogen embrittlement resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention provides a kind of preparation method of aviation fastener, and this preparation method comprises the following steps:

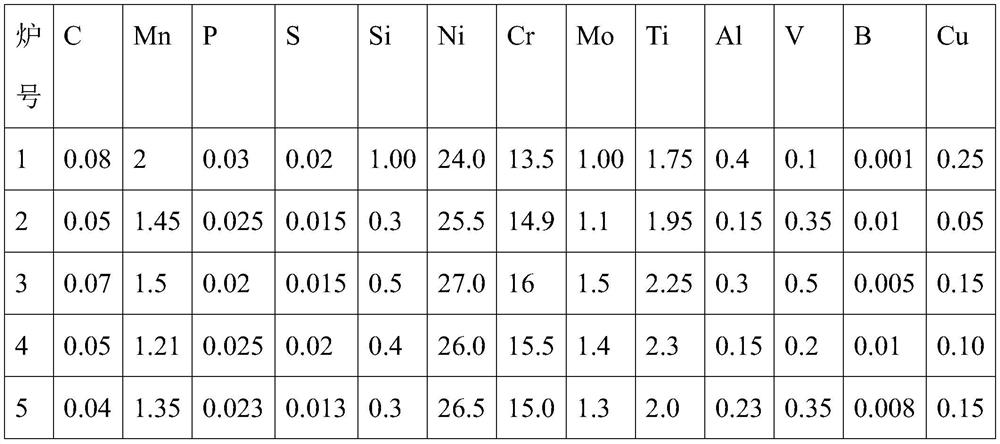

[0022] Step (1), raw material preparation: batching according to the design composition, and all raw materials need to be baked and degassed, wherein, the design composition of the raw materials is as follows: C is ≤0.08%, Mn is ≤2.0%, and P is ≤0.03%, S ≤0.02%, Si ≤1.0%, Ni 24.0-27.0%, Cr 13.5-16.0%, Mo 1.0-1.5%, Ti 1.75-2.3%, Al ≤0.4%, V is 0.1-0.5%, B is 0.001-0.010%, Cu is ≤0.25%, and the balance is Fe. Specifically, for example, according to the procurement technical requirements and procurement plan, purchase the required smelting raw materials from qualified suppliers, and require the product quality certificate of the raw materials. The acceptance of raw materials is carried out in accordance with the provisions of the "Enterprise Product Technical Specifications", and the raw materials must meet the technical requiremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com