Forging-rolling composite processing and heat treatment process of a near-α-type high-temperature titanium alloy

A high-temperature titanium alloy and composite processing technology, which is applied in the field of titanium alloy preparation, can solve problems such as narrow temperature windows, and achieve the effects of reducing waste, saving costs, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

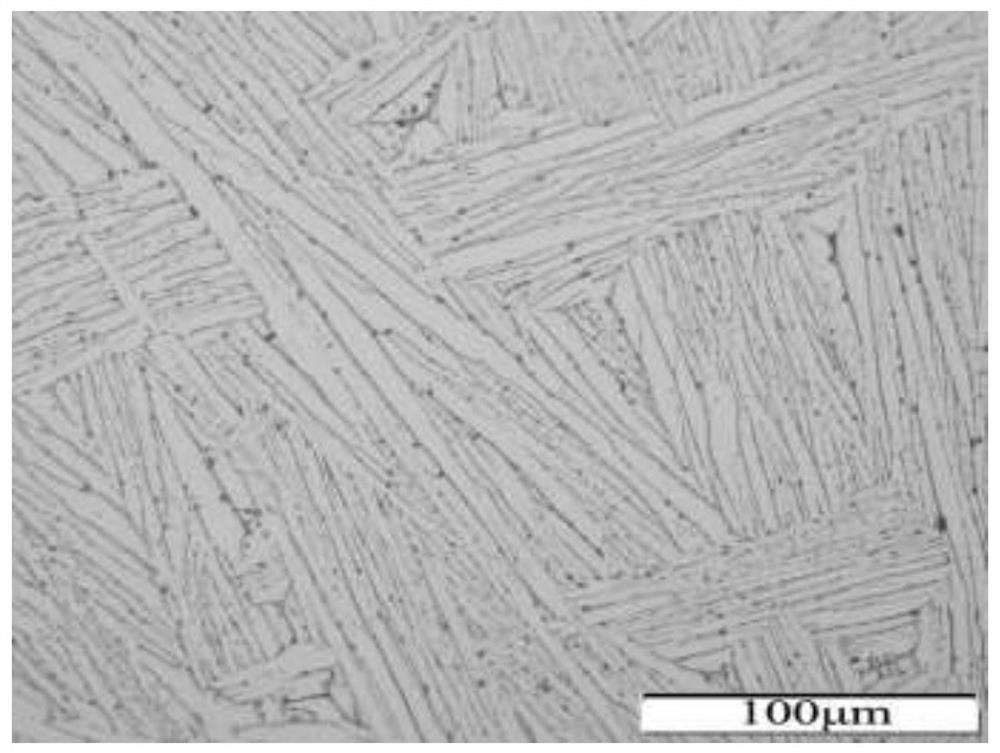

Embodiment 1

[0033] The near-α type high-temperature titanium alloy of this embodiment has the composition elements by mass percentage as Al: 6.0%, Sn: 3.0%, Zr: 2.5%, Mo: 0.5%, Nb: 1.0%, Ta: 1.0%, Si : 0.4%, Er: 0.2%, the rest is Ti, the high-temperature titanium alloy ingot is obtained by conventional casting method, and then the β / (α+β) phase transition point of the alloy is obtained by DSC (differential scanning calorimeter) test. 1014°C. In the first step, the 1150°C beta single-phase zone forging is carried out, and then the Widmandarin bar is forged in the 1014°C beta phase zone. In the second step, the material with an equiaxed structure obtained in the first step was heated to 980° C. for 20 minutes, and the first pass was rapidly rolled with a deformation amount of 10%. In the third step, the alloy material obtained in the second step is subjected to a second pass of hot rolling, the alloy of the second step is returned to the furnace for 5 minutes, the hot rolling temperature i...

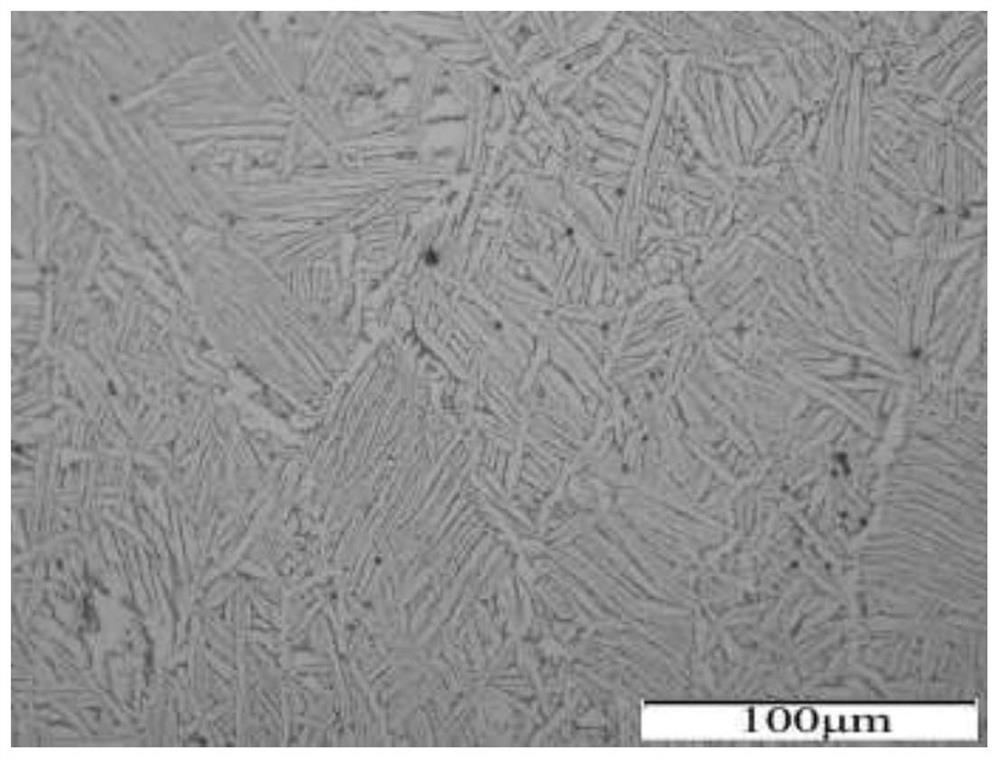

Embodiment 2

[0035]The near-α type high-temperature titanium alloy of this embodiment has the composition elements by mass percentage as Al: 6.0%, Sn: 3.0%, Zr: 2.5%, Mo: 0.5%, Nb: 1.0%, Ta: 1.0%, Si: 0.4%, Er: 0.2%, the rest is Ti, the high temperature titanium alloy ingot is obtained by conventional casting method, and then the β / (α+β) phase transition point of the alloy is obtained by DSC (differential scanning calorimeter) test and is 1014 °C. The first step is to open up and forge through the 1150 ℃ beta single-phase region, and then forge the Widmanners structure bar in the 1014 ℃ β phase region. In the second step, the material with an equiaxed structure obtained in the first step was heated to 980° C. for 20 minutes, and the first pass was rapidly rolled with a deformation amount of 11%. In the third step, the alloy material obtained in the second step is subjected to a second pass of hot rolling, the alloy in the second step is returned to the furnace for 5 minutes, the hot rolli...

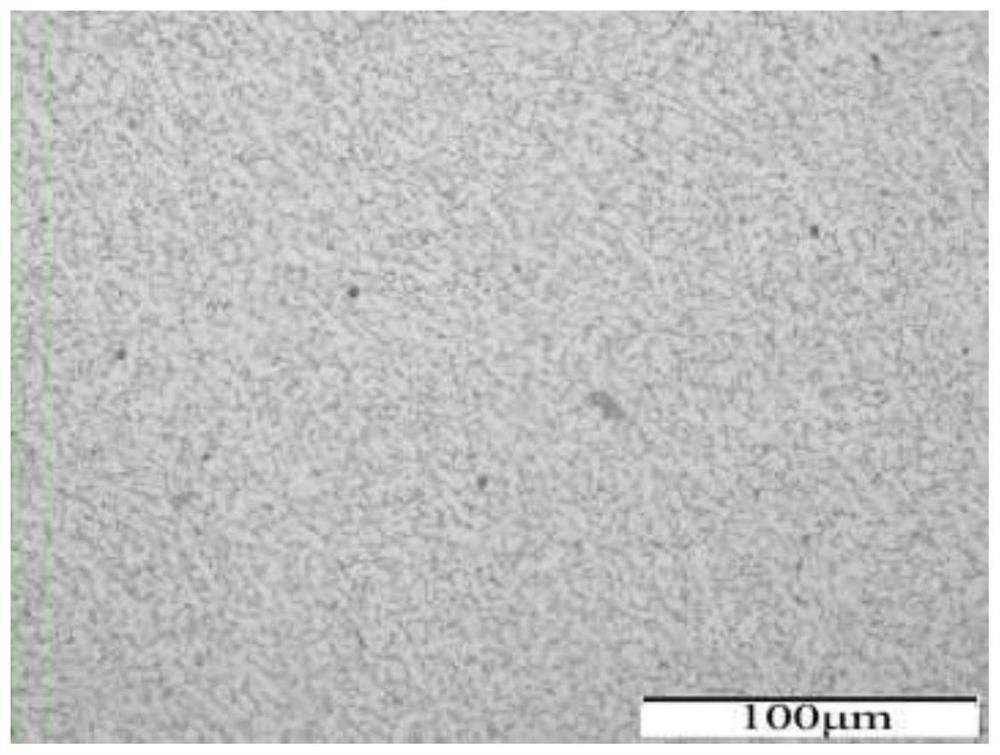

Embodiment 3

[0037] The near-α type high-temperature titanium alloy of this embodiment has the composition elements by mass percentage as Al: 6.0%, Sn: 3.0%, Zr: 2.5%, Mo: 0.5%, Nb: 1.0%, Ta: 1.0%, Si: 0.4%, Er: 0.2%, the rest is Ti, the high temperature titanium alloy ingot is obtained by conventional casting method, and then the β / (α+β) phase transition point of the alloy is obtained by DSC (differential scanning calorimeter) test and is 1014 °C. The first step is to open up and forge through the 1150 ℃ beta single-phase region, and then forge the Widmanners structure bar in the 1014 ℃ β phase region. In the second step, the material with an equiaxed structure obtained in the first step was heated to 980° C. for 20 minutes, and the first pass was rapidly rolled with a deformation amount of 10%. In the third step, the alloy material obtained in the second step is subjected to a second pass of hot rolling, the alloy of the second step is returned to the furnace for 5 minutes, the hot roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com