Lifting type loader

A loader and lift-type technology, applied in the direction of earth mover/shovel, mechanically driven excavator/dredger, construction, etc. Influence and other problems, to achieve the effect of improving the height of reclaiming and unloading, reducing the labor intensity of workers, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

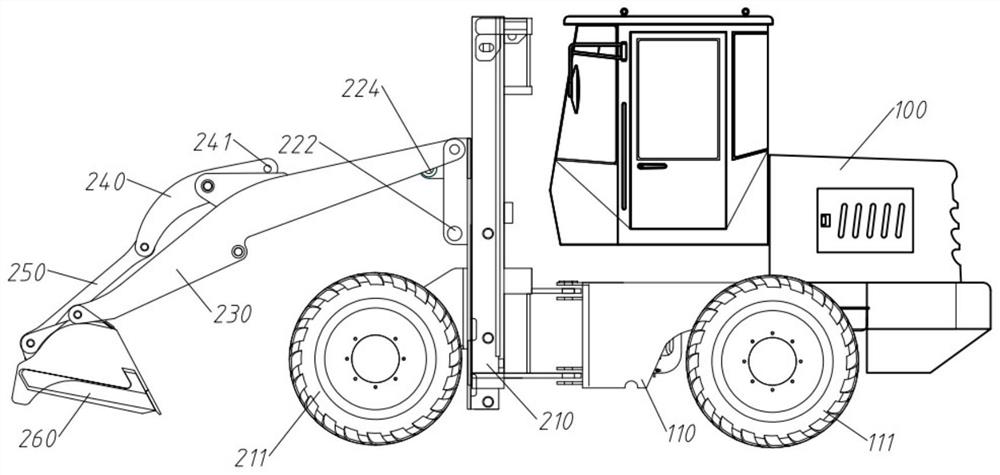

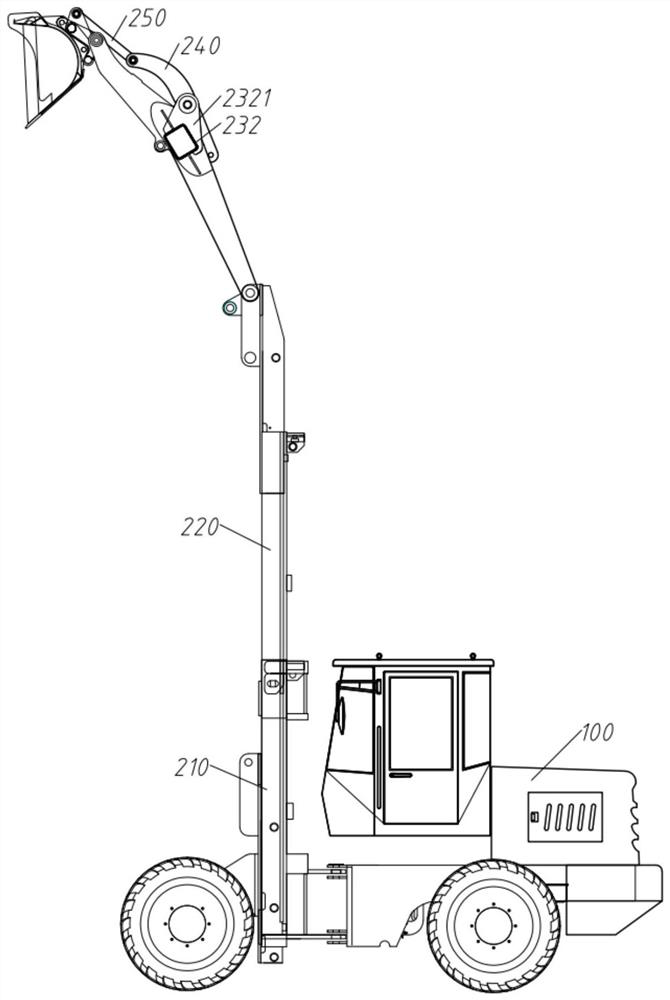

[0028] Such as figure 1 As shown, a lifting loader is disclosed in this embodiment, which includes a car body 100. The base 110 of the car body 100 is hinged with a fixing frame 210 through a first driving mechanism. The function of the first driving mechanism is mainly to realize 210 relative to the steering of the base 110 on the horizontal plane, in the actual design process, the first driving mechanism can choose a steering cylinder or other steering drive.

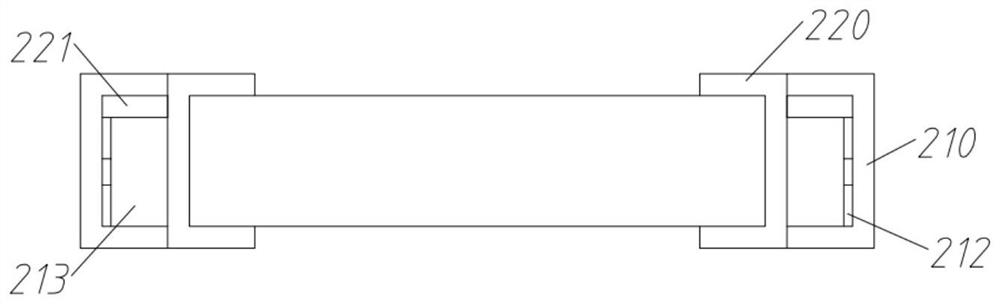

[0029] Two rear wheels 111 are rotatably arranged on the base 110, and two front wheels 211 are rotatably arranged at the bottom of the fixed frame 210; It can move vertically along the fixed frame 210 under driving; the function of the second driving mechanism is to make the lifting frame 220 rise or fall vertically relative to the fixed frame 210. In the actual design process, the second driving option has a straight line The driving mechanism of the movement, such as a cylinder, an electric cylinder or an oil cyli...

Embodiment 2

[0037] Such as Figure 5 and Figure 6 As shown, the lifting loader of this embodiment is basically the same as that of Embodiment 1, the difference is that the material retrieving mechanism of this embodiment is a gripper mechanism 270 including a gripper upper cover 271 and a gripper lower cover 272, Both sides of the handle lower cover 272 are respectively hinged with the end of the boom 230, the middle part of the handle lower cover 272 is hingedly connected with the connecting rod 250, the handle upper cover 271 is hingedly connected with the handle lower cover 272, and the reclaiming mechanism Also includes a fifth drive mechanism, the fifth drive mechanism is used to control the handle upper cover 271 to rotate around its hinge with the handle lower cover 272, and then realize the handle upper cover 271 approaching and away from the handle lower cover 272, and then can Clamping and releasing the object to be grasped placed between the gripper upper cover 271 and the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com