Portable in-service pipeline mechanical property detection equipment

A kind of testing equipment and portable technology, applied in the field of portable in-service pipeline mechanical performance testing equipment, can solve the problems of loss, oil pipeline shutdown, inconvenient economy, etc., and achieve the effects of light weight, improved accuracy, and reduced probability of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

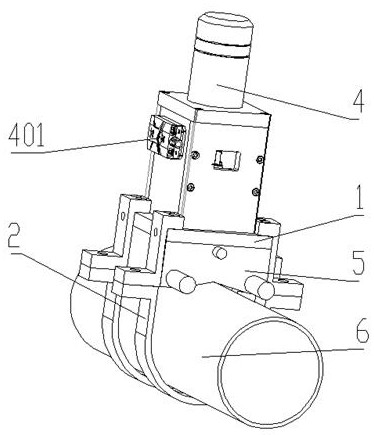

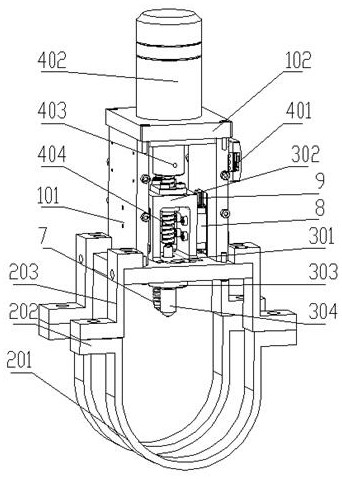

[0026] see Figure 1-Figure 3 , a portable in-service pipeline mechanical performance testing device, including a main engine base plate 1, a pipeline clamping mechanism 2 is arranged under the main engine base plate 1, and a detection mechanism capable of moving up and down, the detection mechanism is arranged inside the main engine base plate 1 and The upper part of the pipe clamping mechanism 2 also includes a transmission mechanism 4 that provides power for the detection mechanism.

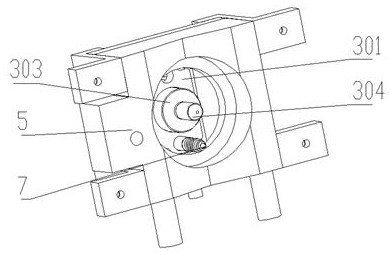

[0027] The detection mechanism includes a moving frame with an upper plate 302 and a lower plate 301, a detection pressure head 304 is arranged at the inner center of the lower plate 301, and a pressure sensor 303 is arranged between the detection pressure head 304 and the lower plate 301;

[0028] The transmission mechanism 4 includes a lead screw 404, the lower end of the lead screw 404 is connected to the upper plate through a threaded connection, and the upper end of the lead screw 404 is ...

Embodiment 2

[0032] see Figure 1-Figure 3 , a portable in-service pipeline mechanical performance testing device, including a main engine base plate 1, a pipeline clamping mechanism 2 is arranged under the main engine base plate 1, and a detection mechanism capable of moving up and down, the detection mechanism is arranged inside the main engine base plate 1 and The upper part of the pipe clamping mechanism 2 also includes a transmission mechanism 4 that provides power for the detection mechanism.

[0033] The detection mechanism includes a moving frame with an upper plate 302 and a lower plate 301, a detection pressure head 304 is arranged at the inner center of the lower plate 301, and a pressure sensor 303 is arranged between the detection pressure head 304 and the lower plate 301;

[0034] The transmission mechanism 4 includes a lead screw 404, the lower end of the lead screw 404 is connected to the upper plate through a threaded connection, and the upper end of the lead screw 404 is ...

Embodiment 3

[0042] see Figure 1-Figure 3, a portable in-service pipeline mechanical performance testing device, comprising a host base plate 1, a pipeline clamping mechanism 2 is arranged below the host base plate 1, and a detection mechanism capable of moving up and down, the detection mechanism is arranged inside the host base plate 1 and The upper part of the pipe clamping mechanism 2 also includes a transmission mechanism 4 that provides power for the detection mechanism.

[0043] The detection mechanism includes a moving frame with an upper plate 302 and a lower plate 301, a detection pressure head 304 is provided at the inner center of the lower plate 301, and a pressure sensor 303 is provided between the detection pressure head 304 and the lower plate 301;

[0044] The transmission mechanism 4 includes a lead screw 404, the lower end of the lead screw 404 is connected to the upper plate through a threaded connection, and the upper end of the lead screw 404 is connected to a motor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com