Cambered surface gloss uniformity detection method

A detection method and uniformity technology, applied in the detection field, can solve the problems of insufficient scientificity of measurement data, misjudgment of detection results, and range limitation, etc., and achieve the effect of not being easily affected by subjective, high detection efficiency, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A method for detecting the gloss uniformity of a curved surface, comprising:

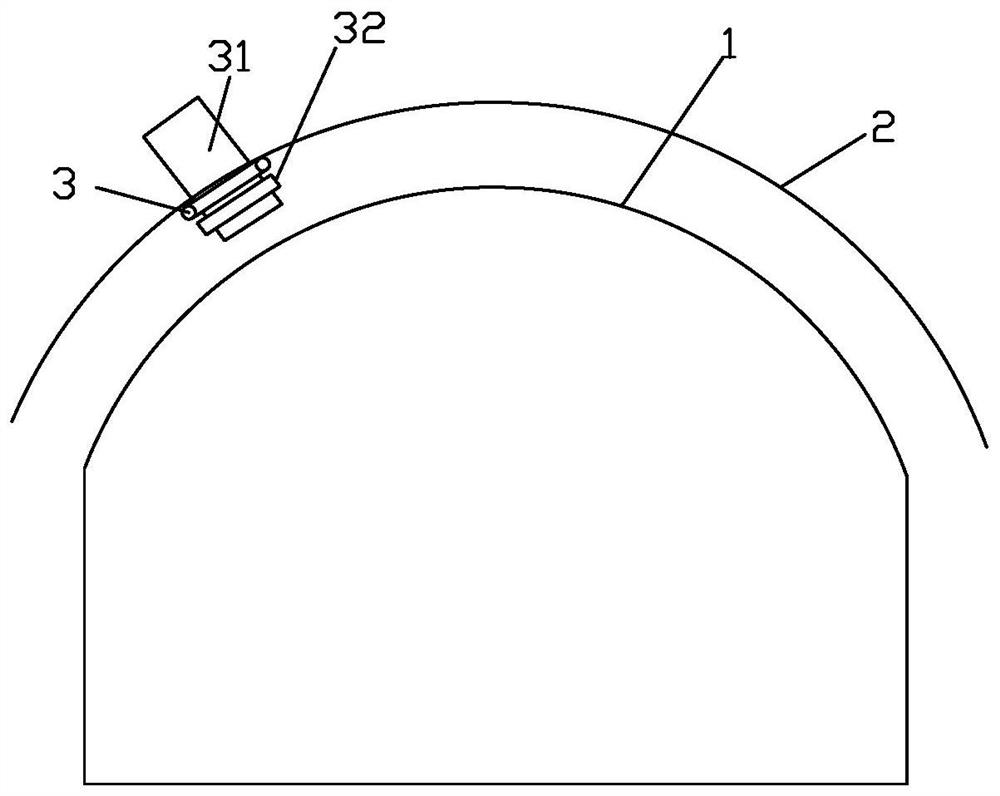

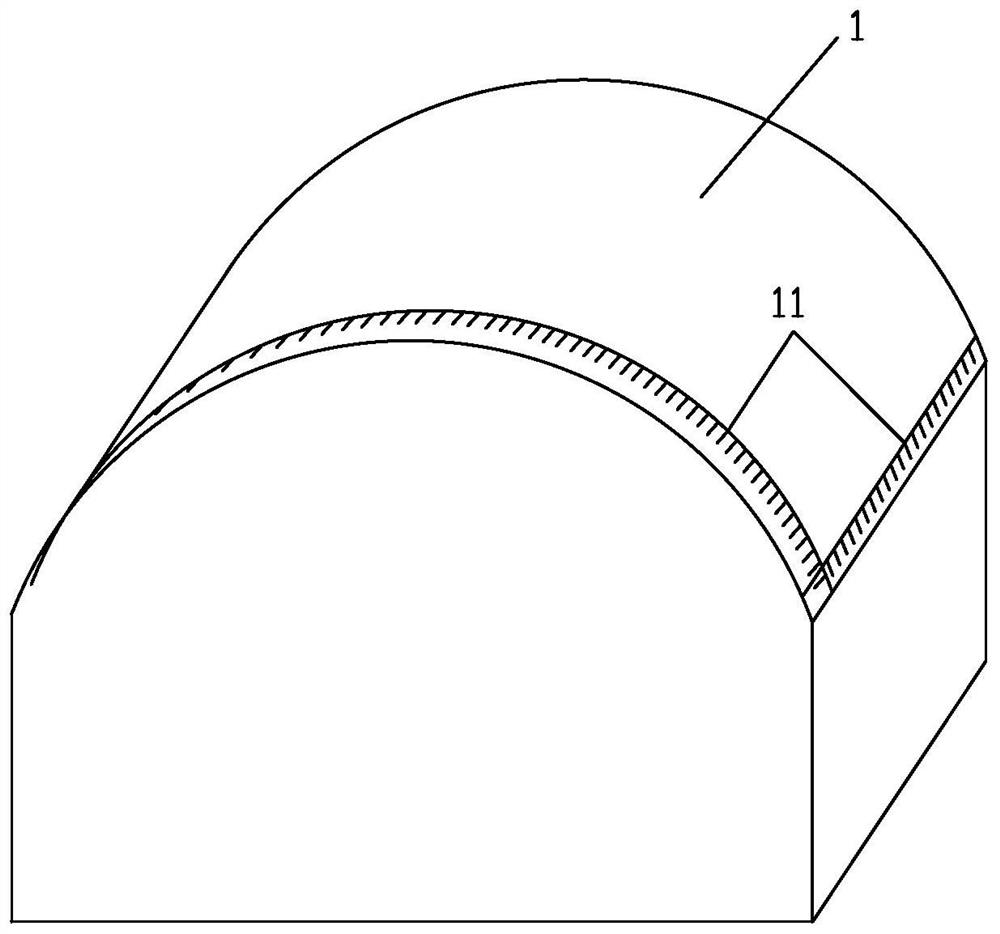

[0035] S1, please refer to figure 1 , select the arc track 2 parallel to the arc surface to be detected at an interval of 1 radian, the arc track 2 is equipped with a camera clamping device 3, the camera clamping device 3 is equipped with a camera, and the camera clamping device 3 and the camera can be mounted together Move along the arc track 2, fix the arc track 2 so that the arc surface 1 to be detected and the arc track 2 are spaced in parallel; the camera includes a camera lens 31, a ring light source 32, a data acquisition system and a screen; the ring light source is clamped on On the camera lens, the ring light source and the camera lens are arranged radially along the arc to face the arc surface to be detected; the data acquisition system connects the camera lens and the screen through the data line, so that the pictures taken by the camera lens can be viewed in real time through the...

Embodiment 2

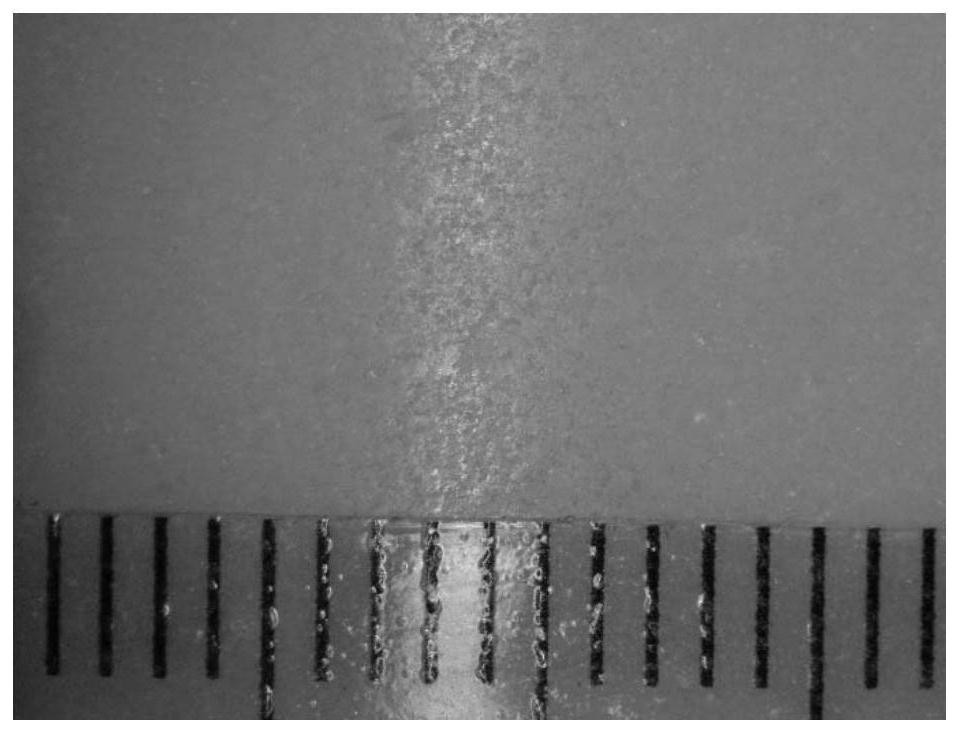

[0051] It differs from Embodiment 1 in that: through processing, a binary image such as Figure 8 shown.

[0052] Such as Figure 9 As shown, along the detection direction, take continuous areas with an area of 3 mm × 3 mm for statistics on the proportion of black pixels, and the proportion of black pixels in the 8 areas can be obtained as follows:

[0053]a1=11433÷(620×620)=2.97%;

[0054] a2=13237÷(620×620)=3.44%;

[0055] a3=29336÷(620×620)=7.63%;

[0056] a4=17130÷(620×620)=4.46%;

[0057] a5=10038÷(620×620)=2.61%;

[0058] a6=3951÷(620×620)=1.03%;

[0059] The maximum fluctuation range of the data is 7.63%-1.03%=6.6%>5%, indicating that the data fluctuates greatly, and the surface of the arc is uneven.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com