Manufacturing method of novel printer carbon powder

A manufacturing method and printer technology, applied in the field of toner, can solve problems such as nose, allergy, even dizziness, vomiting, and irritation of human mucous membranes, which are easy to increase the incidence of asthma, so as to reduce nose allergy, protect physical health, and prevent irritation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

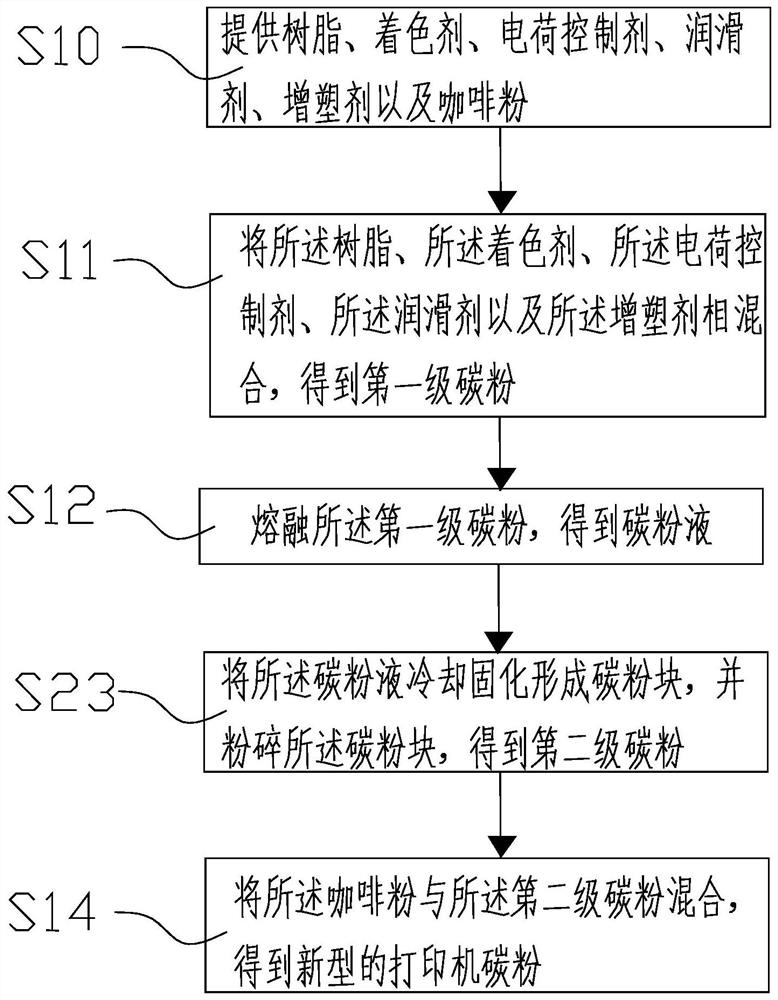

[0036] figure 1 , is a schematic flow chart of the first embodiment of the present invention, a novel method for manufacturing printer toner, including:

[0037] Step S10, providing resin, colorant, charge control agent, lubricant, plasticizer and coffee powder;

[0038] Step S11, mixing resin, colorant, charge control agent, lubricant and plasticizer to obtain first-level carbon powder;

[0039] In this step, 35-95 parts by mass of resin, 10-60 parts by mass of colorant, 0.2-8 parts by mass of charge control agent, 5-15 parts by mass of lubricant and 0.1-7 parts by mass of plasticizer are mixed to obtain primary toner;

[0040] Through the above steps, the image of the obtained toner can be made more stable during printing, and it is more convenient for the toner cartridge to absorb the toner according to the image, and print the toner on the paper to complete the function of printing or copying.

[0041] Step S12, melting the first-stage carbon powder to obtain a liquid c...

Embodiment 2

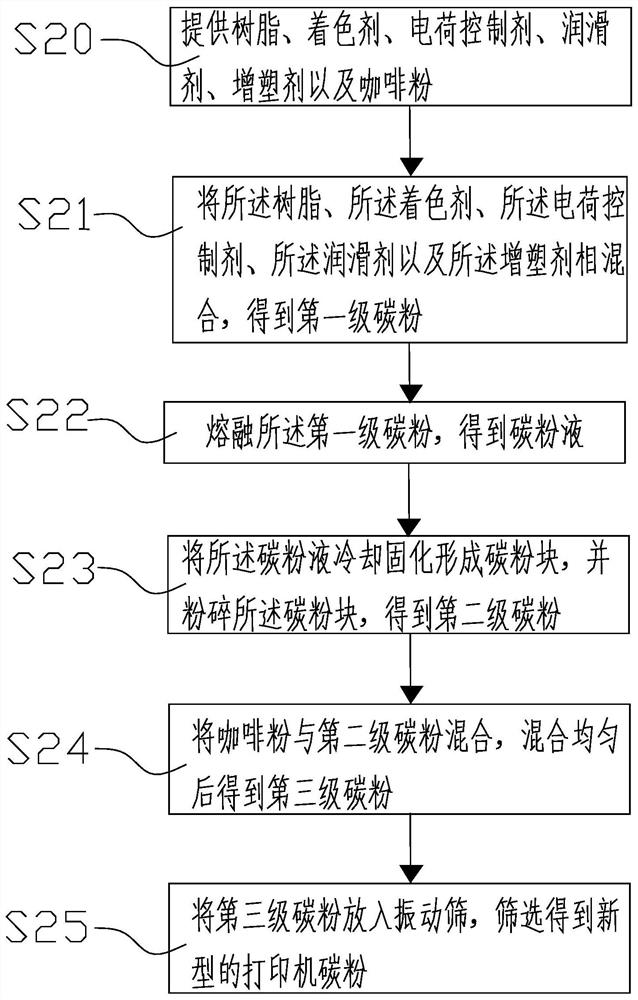

[0050] figure 2 , is a schematic flow chart of the second embodiment of the present invention, a novel method for manufacturing printer toner, including:

[0051]Step S20, providing resin, colorant, charge control agent, lubricant, plasticizer and coffee powder;

[0052] Step S21, mixing resin, colorant, charge control agent, lubricant and plasticizer to obtain first-level carbon powder;

[0053] In this step, 35-95 parts by mass of resin, 10-60 parts by mass of colorant, 0.2-8 parts by mass of charge control agent, 5-15 parts by mass of lubricant and 0.1-7 parts by mass of plasticizer are mixed to obtain primary toner;

[0054] Through the above steps, the image of the obtained toner can be made more stable during printing, and it is more convenient for the toner cartridge to absorb the toner according to the image, and print the toner on the paper to complete the function of printing or copying.

[0055] In this step, put the resin, colorant, charge control agent, lubric...

Embodiment 3

[0078] Novel printer toner is manufactured by the above-mentioned manufacturing method of printer toner.

[0079] Through the above structure, since the new printer toner includes resin, colorant, charge control agent, lubricant, plasticizer and coffee powder, when the toner in the toner cartridge or powder box or powder cartridge is melted into the paper fiber by high temperature, the new type The coffee powder in the printer toner is melted with the resin at high temperature. The coffee powder produces a coffee-like smell when it melts. The coffee-flavored smell overwhelms the irritating gas produced when the resin melts, effectively preventing the resin from melting. Gases with pungent odors can irritate human mucous membranes, reduce the incidence of asthma or nasal allergies, and even dizziness and vomiting, so as to protect people's health.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com