Polynomial chaos-based turbine blade tip gas thermal performance uncertainty quantification system

An uncertain and polynomial technology, applied in character and pattern recognition, instruments, geometric CAD, etc., can solve problems such as long numerical calculation time, achieve the effect of improving calculation efficiency, increasing calculation accuracy, and reducing calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

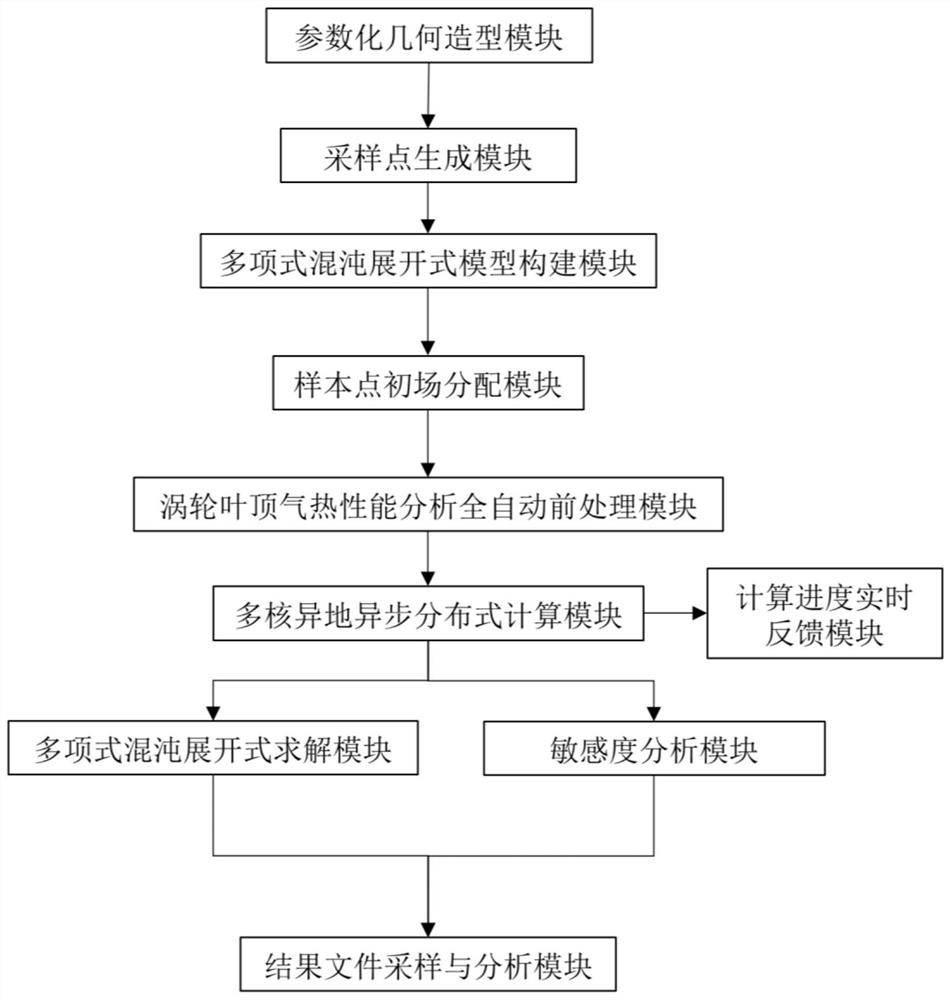

[0034] Such as figure 1 As shown, the present invention is a polynomial chaos-based gas-thermal performance uncertainty quantification system at the tip of a turbine blade, which mainly includes:

[0035] 1. The parameterized geometric modeling module uses the coordinates of the starting point and end point of the arc in the blade tip and the blade height as the key parameters of the geometric modeling of the blade tip to establish the geometric modeling of the blade tip;

[0036] 2. The sampling point generation module takes the number of random variables and the probability density distribution function as input, uses the Symolyak sparse grid technology to sample the sample point space according to the leaf tip geometry generated by the parametric geometric modeling module, and generates polynomial chaos The sample point distribution data req...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com