Pattern etching method for double-glass photovoltaic module

A double-glass photovoltaic and component technology, which is applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve problems such as expensive laser equipment, large-scale production limitations, and slow processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

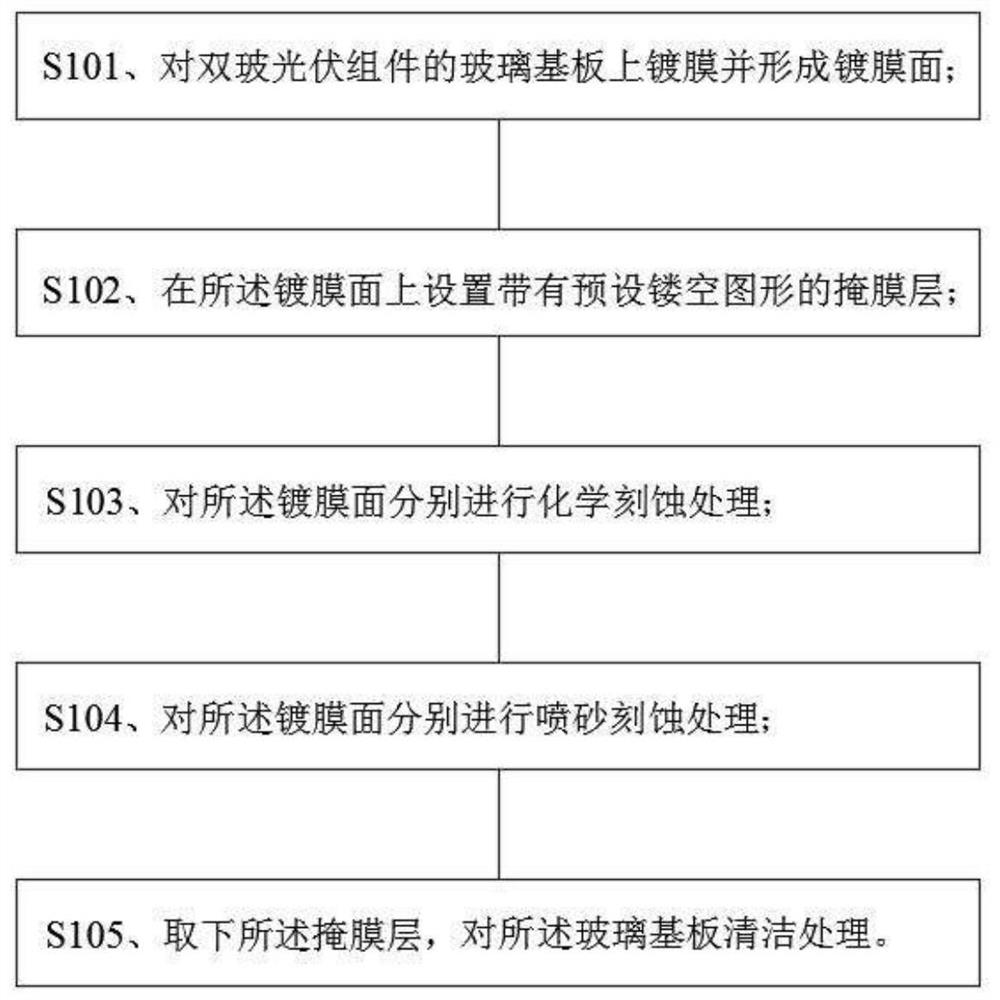

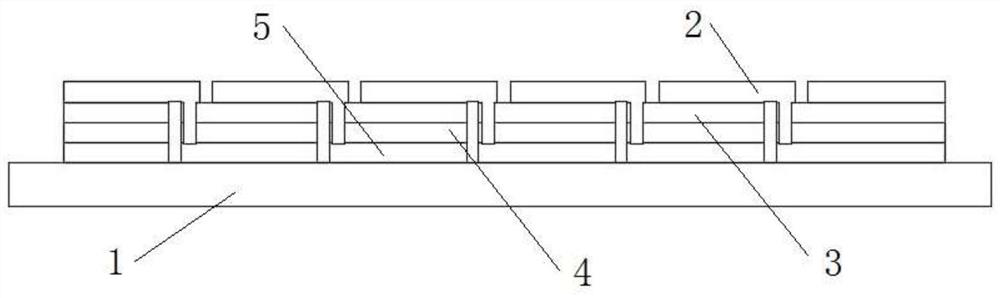

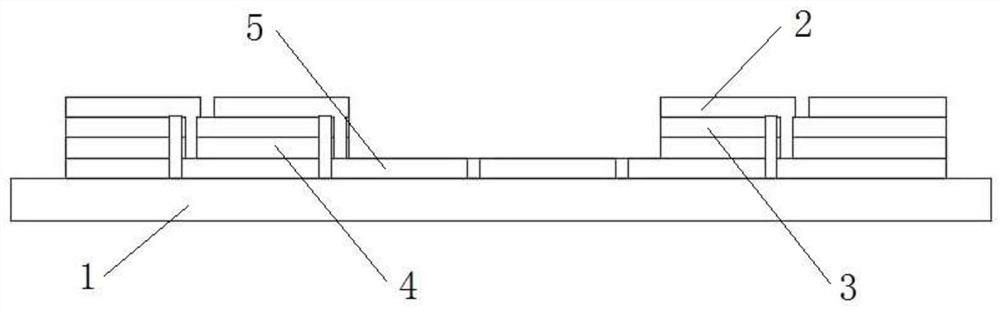

[0026] An embodiment of the present invention provides a method for etching a pattern of a double-glass photovoltaic module, such as figure 1 , 2 , 3 and 4, including:

[0027] S101, coating the glass substrate 1 of the double-glass photovoltaic module and forming a coating surface;

[0028] Here, the double-glass photovoltaic module includes a glass substrate 1 and a coating surface arranged in sequence from bottom to top, and the coating surface includes a TCO film layer 5, a CdTe power generation layer 3, a CdS power generation layer 4, and a Mo film layer 2 from bottom to top, During implementation, the glass substrate 1 of the double-glass photovoltaic module needs to be cleaned, coated and connected in series. Specifically, for the glass substrate 1 with a TCO (transpa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com