A prefabricated and intelligent maintenance pedestal for cover beams

An intelligent, beam-covering technology, applied in manufacturing tools, ceramic molding machines, piping systems, etc., can solve the problem of single function of the maintenance pedestal, and achieve the effect of not easy to damage, easy to lift or transport

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

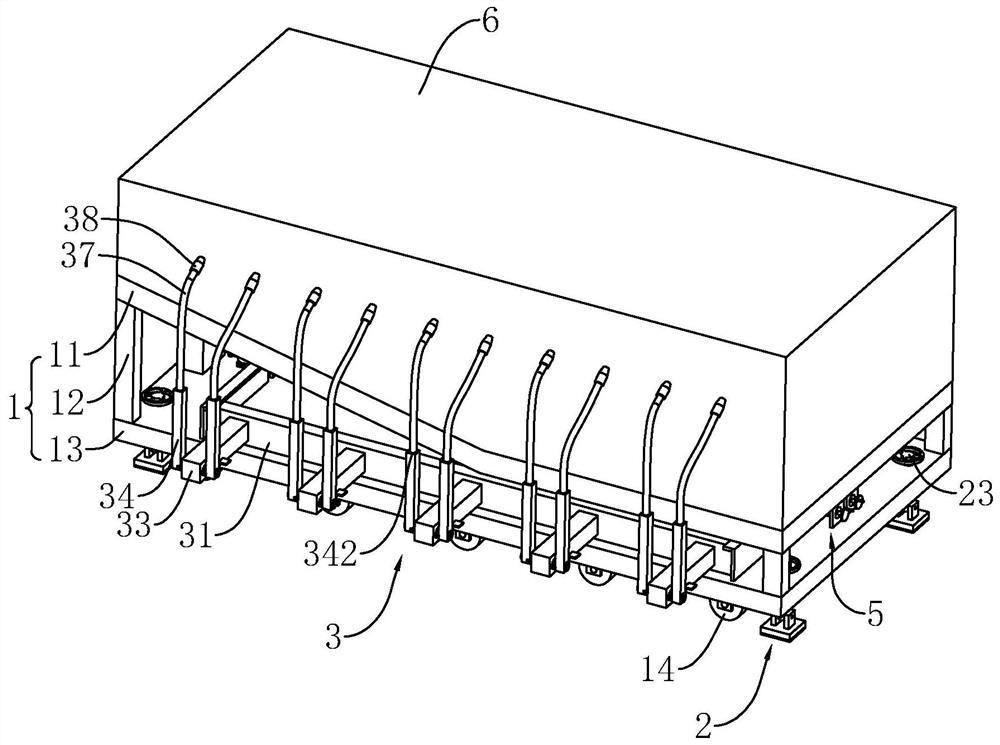

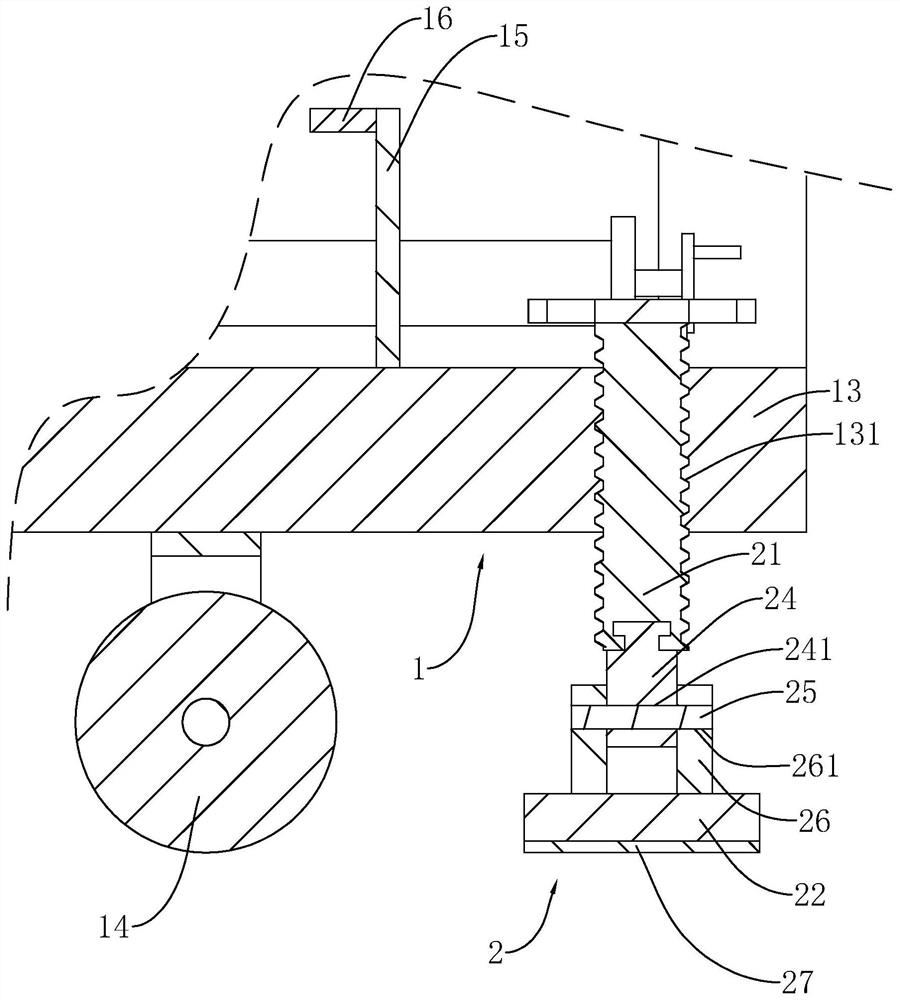

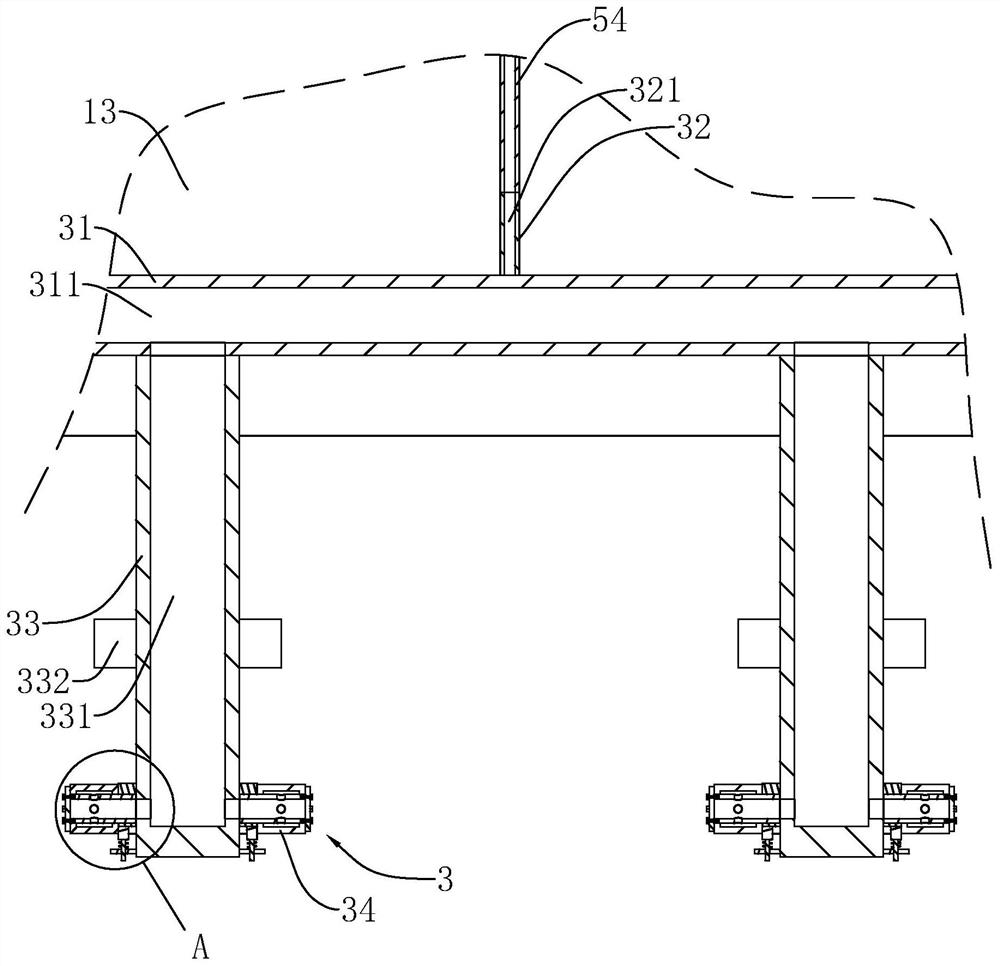

[0038] The following is attached Figure 1-7 The application is described in further detail.

[0039] This embodiment discloses a cover beam prefabrication and intelligent maintenance pedestal. refer to figure 1 , the maintenance pedestal includes a support frame 1, and the upper end surface of the support frame 1 is used for placing a concrete member 6.

[0040] refer to figure 1 , the support frame 1 includes a first support plate 11 , a support rod 12 and a second support plate 13 . There are multiple support rods 12, the upper end surfaces of the plurality of support rods 12 are fixedly connected with the lower end surface of the first support plate 11, and the lower end surfaces of the plurality of second support plates 13 are fixed with the upper end surface of the second support plate 13. connect.

[0041] refer to figure 1 , the lower end surface of the second support plate 13 is fixedly connected with a plurality of universal wheels 14, the maintenance platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com