Novel lining device of cast-in-place large-diameter pipe pile and pipe pile construction method

A large-diameter pipe and construction method technology, applied in sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of material waste, inability to further save costs, inability to effectively recover non-pipe pile materials, etc., to ensure concrete strength, Achieve the effect of material recovery and reduction of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

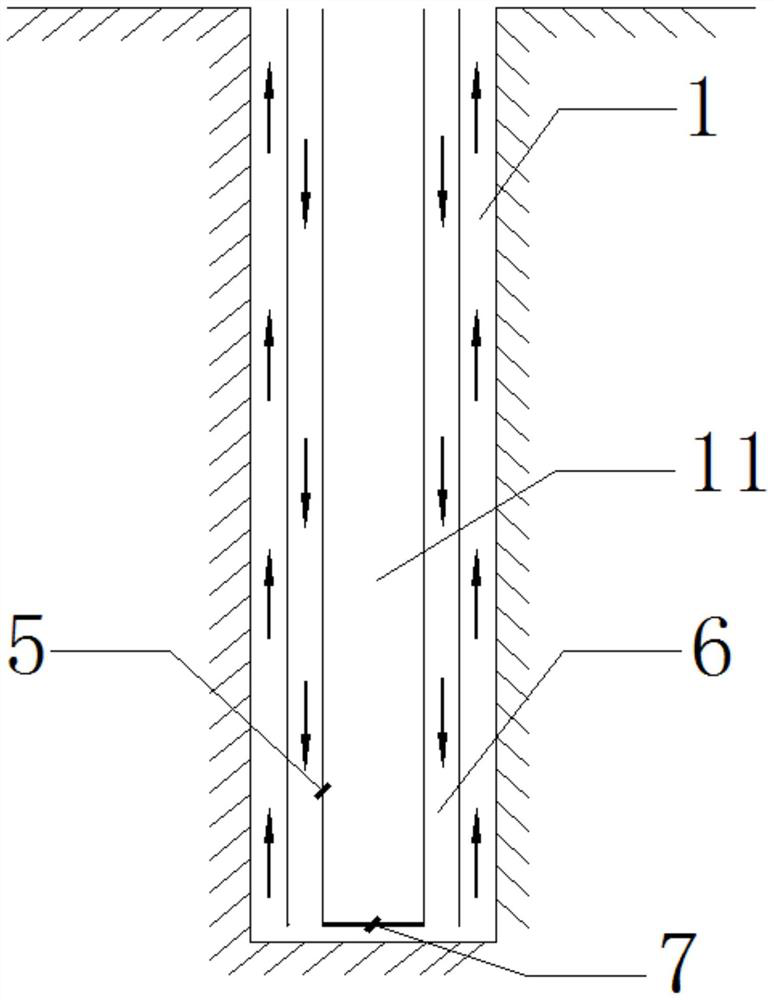

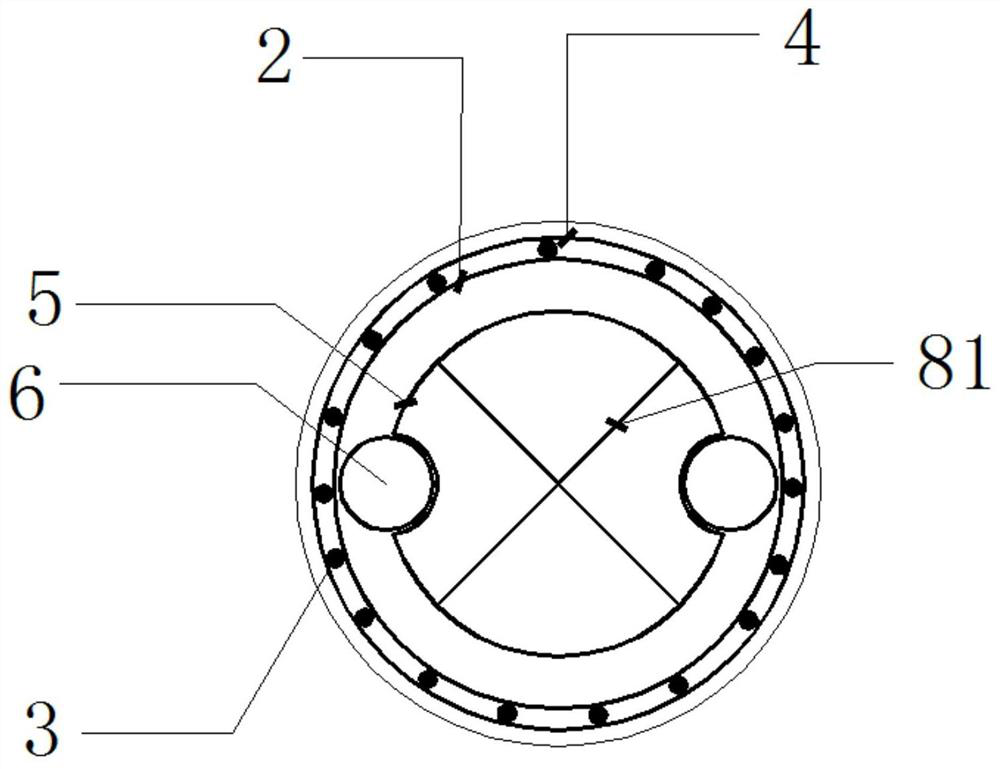

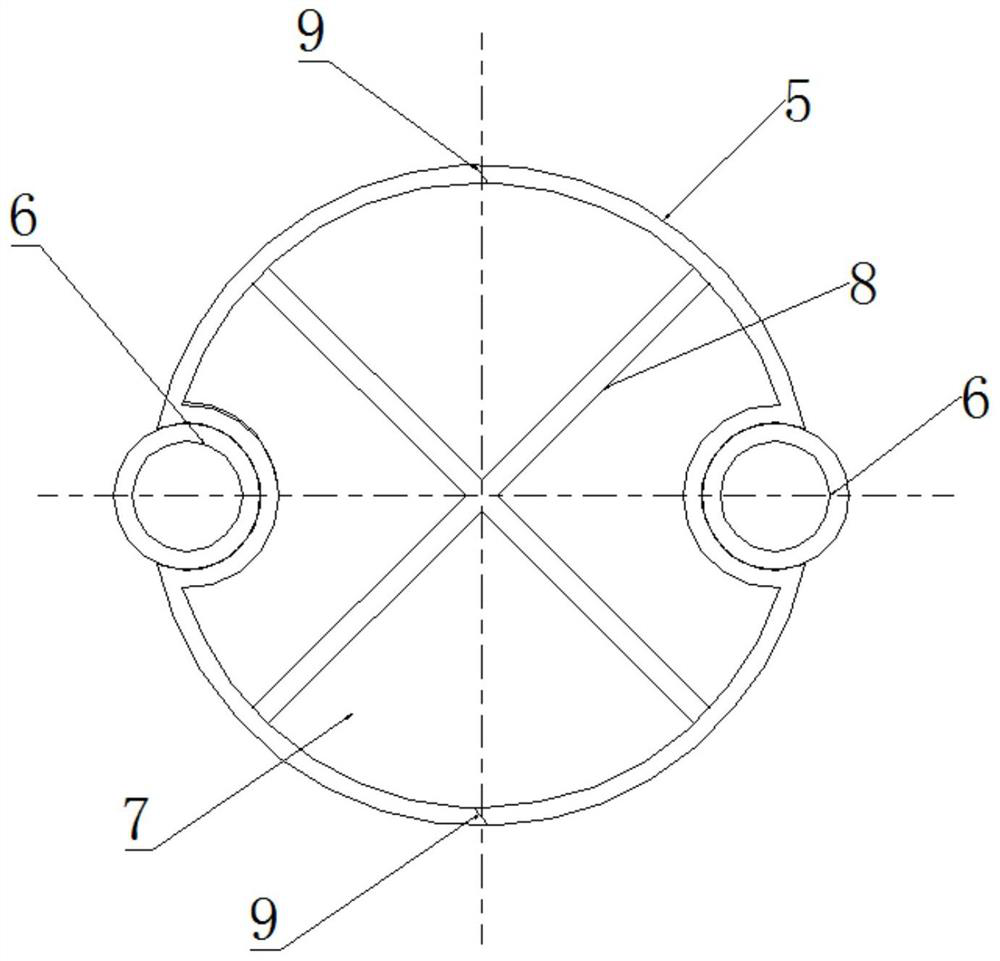

[0040] Such as Figure 1-8 As mentioned above, the present invention provides a new type of lining device for cast-in-place large-diameter pipe piles, including a lining pipe 5 spliced by two lining steel molds 51, and the outer wall of the lining pipe 5 slides It is connected with a conduit 6 extending in the same direction. During pouring, the conduit 6 is pulled up with the liquid level of the concrete. The inner liner 5 is provided with a cross brace 81, and the inner steel mold on the two pages passes through the cross brace 81 It is detachably fixedly connected, and the bottom end of the inner liner pipe 5 is fixedly connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com