Simple oil well wax removing device

A technology for cleaning devices and oil wells, which is applied to cleaning equipment, wellbore/well components, measurement, etc., and can solve problems such as complex equipment, high energy consumption of electric heating, and uneconomical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

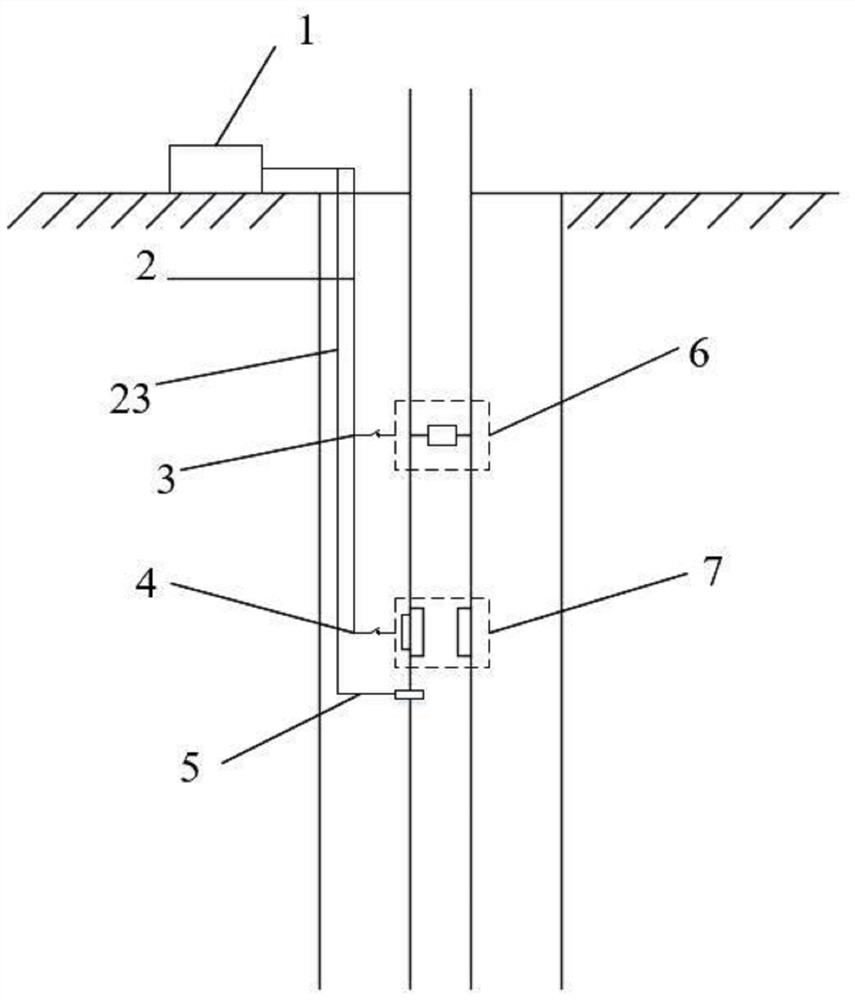

[0013] A simple oil well wax removal device, the structure is as follows figure 1 As shown, it mainly includes two modules distributed on the outer wall of the tubing 8 : a mechanical wax removal module 6 , a chemical wax removal and prevention module 7 and a thickness sensor 5 . Among them, the mechanical wax removal module 6 is connected to the first cable 2 through the first control valve 3, and the chemical wax removal and anti-wax module 7 is connected to the first cable 2 through the second control valve 4. The above two modules are connected through the first cable 2 and the Inoue control box 1 connection. A thickness sensor 5 is arranged below the chemical wax removal and anti-wax module 7, and the thickness sensor 5 is connected with the control box 1 on the well through a second cable 23.

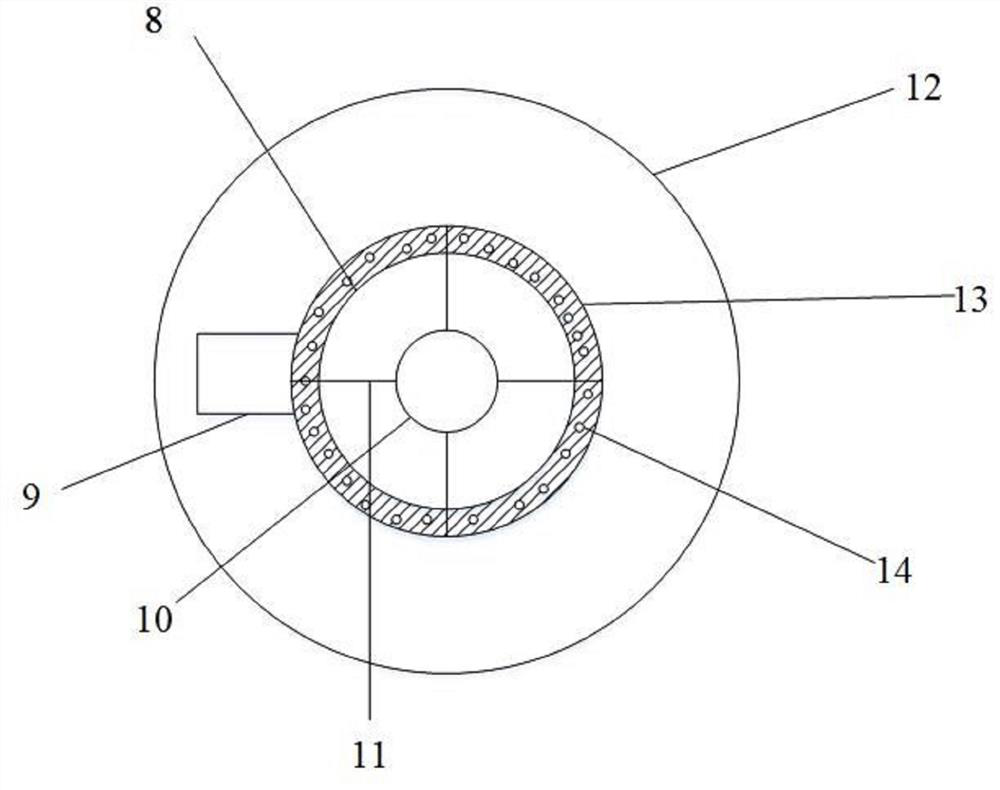

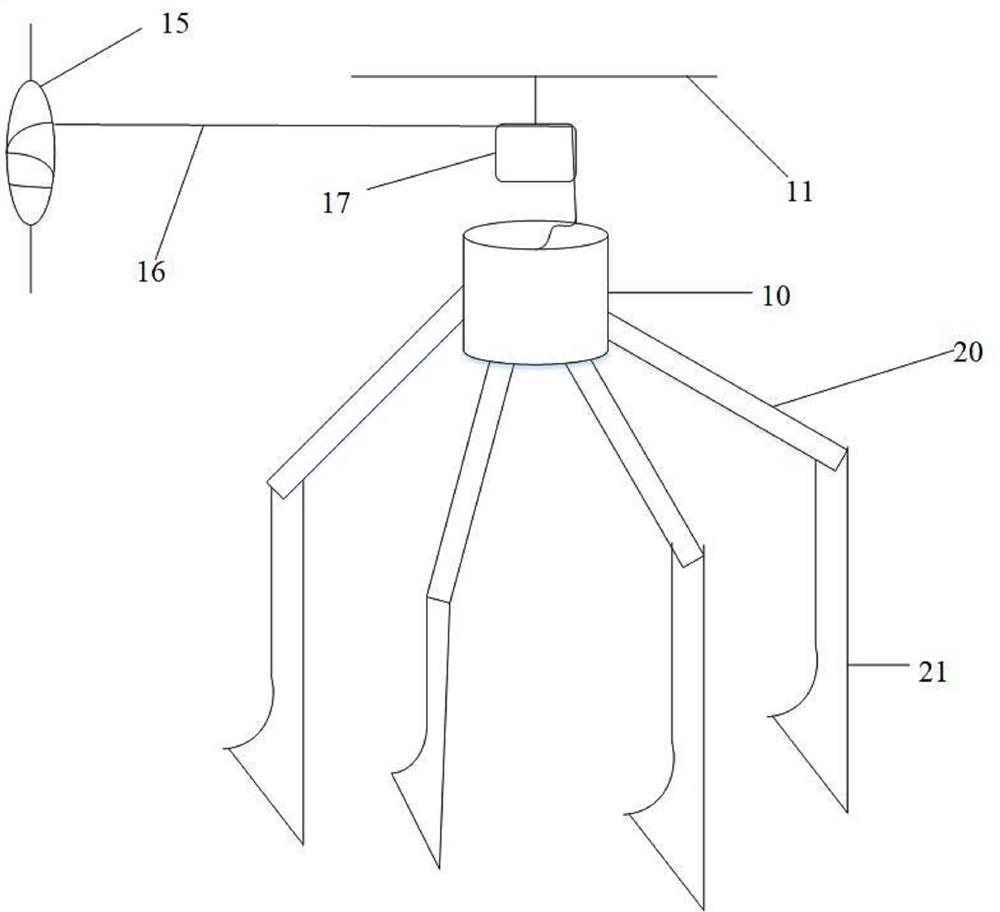

[0014] Such as figure 2 and image 3 As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com