Visual high-temperature and high-pressure fracture-cavity simulation system and use method thereof

A simulation system, high temperature and high pressure technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of size and connection relationship, difference, real-time observation of fluid flow status, etc., to improve reliability Operability and flexibility, effect of reducing experiment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

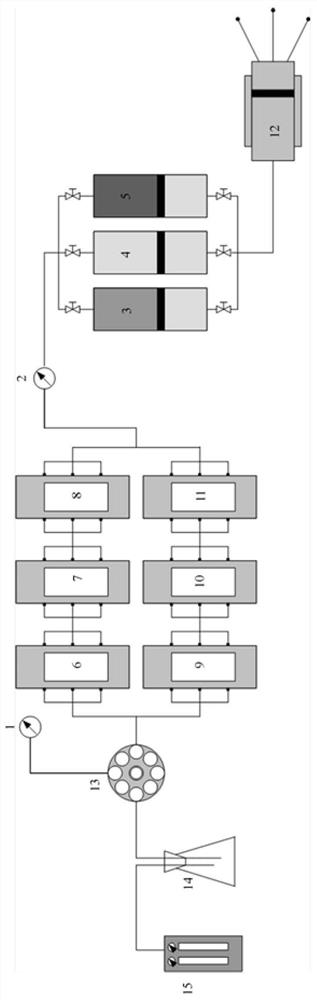

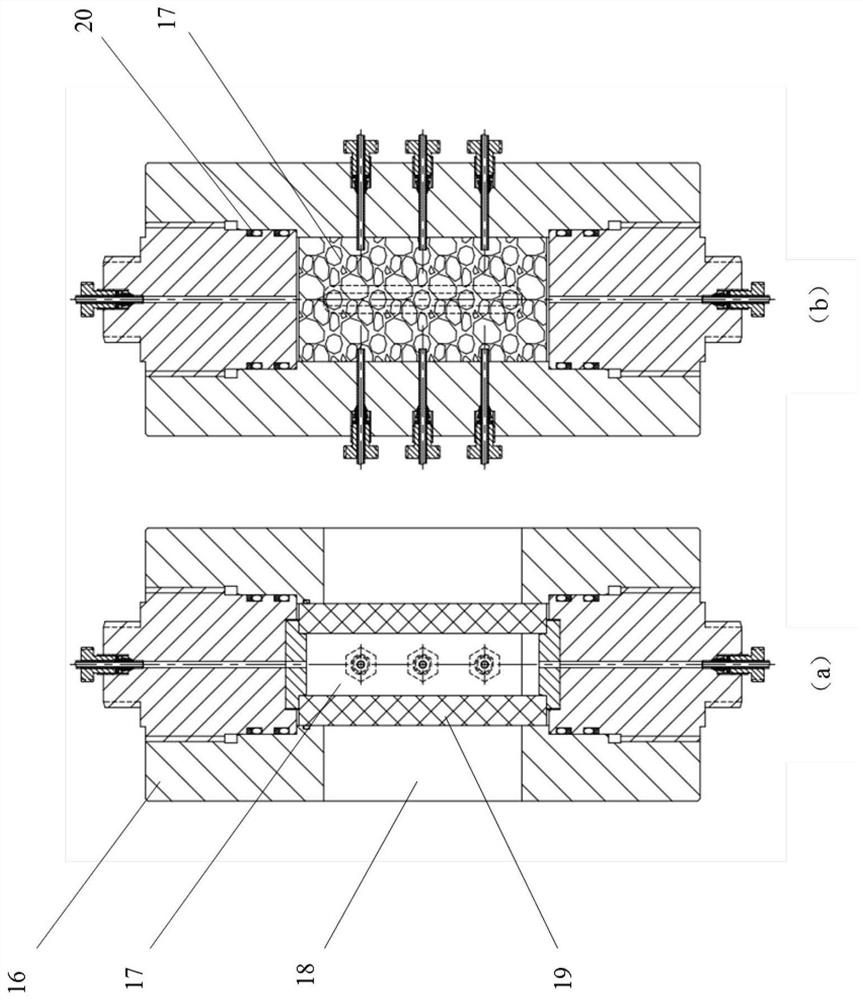

[0027] Such as figure 1 As shown, a visualized high-temperature and high-pressure fracture-cavity simulation system includes: a fracture-cavity simulation system, a first pressure gauge 1, a second pressure gauge 2, an advection pump 12, an intermediate container system, a back pressure valve 13, and a gas-liquid separator 14 and gas meter 15; the advection pump 12, the intermediate container system, the second pressure gauge 2, the crack hole simulation system, the back pressure valve 13, the gas-liquid separator 14 and the gas volume The meter 15 is connected in turn through pipelines, and the first pressure gauge 1 is connected with the back pressure valve 13 through pipelines; the intermediate container system is used for injecting experimental fluid into the crack-hole simulation system, and the crack-hole simulation system The system is used to provide the formation environment required for the experiment.

[0028] The intermediate container system includes a simulated ...

Embodiment 2

[0040] A method for using a visualized high-temperature, high-pressure fracture-cavity simulation system. The advection pump 12 pressurizes the simulated formation water intermediate container 5, and injects simulated formation water into the fracture-cavity simulation system. When the fracture-cave simulation After the system is saturated with simulated formation water, close the inlet and outlet valves of the simulated formation water intermediate container 5; then pressurize the simulated oil intermediate container 3 through the advection pump 12, and inject simulated oil into the fracture-cavity simulation system , when the fracture-cavity simulation system is saturated with simulated oil, build up the pressure of the fracture-cavity simulation system, and then close the inlet and outlet valves of the simulated oil intermediate container 3, so as to establish the original formation pressure and original water saturation , oil saturation, and then depletion experiments, wate...

Embodiment 3

[0042] In the fracture-cavity simulation system, depletion experiments, water flooding experiments and gas injection flooding experiments were carried out to simulate three stages of oil and gas field development: depletion production, water flooding production and gas injection flooding production stages, to clarify the oil displacement of different production methods The mechanism and the distribution position of the remaining simulated oil after each stage are used to guide and improve the development method of Tahe carbonate fracture-vuggy reservoir.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com