Precise measurement method for free bending forming size of pipe plane

A technology of bending forming and measuring method, applied in the direction of measuring devices, instruments, and optical devices, etc., can solve the problems of limited surface area of flat projectors, large size limitations of elbow fittings, and difficulty in guaranteeing measurement accuracy, and achieves good results. The effect of promoting application value, filling industry gaps, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments, but this should not be used as a limitation to the protection scope of the present application.

[0042] A method for accurately measuring the dimensions of free-bending pipes in a flat plane, characterized in that the method comprises the following steps:

[0043] Step 1: Scan the actual planar elbow with a scanner to generate a point cloud image of the entire pipe, and generate a solid elbow model after surface fitting the point cloud image;

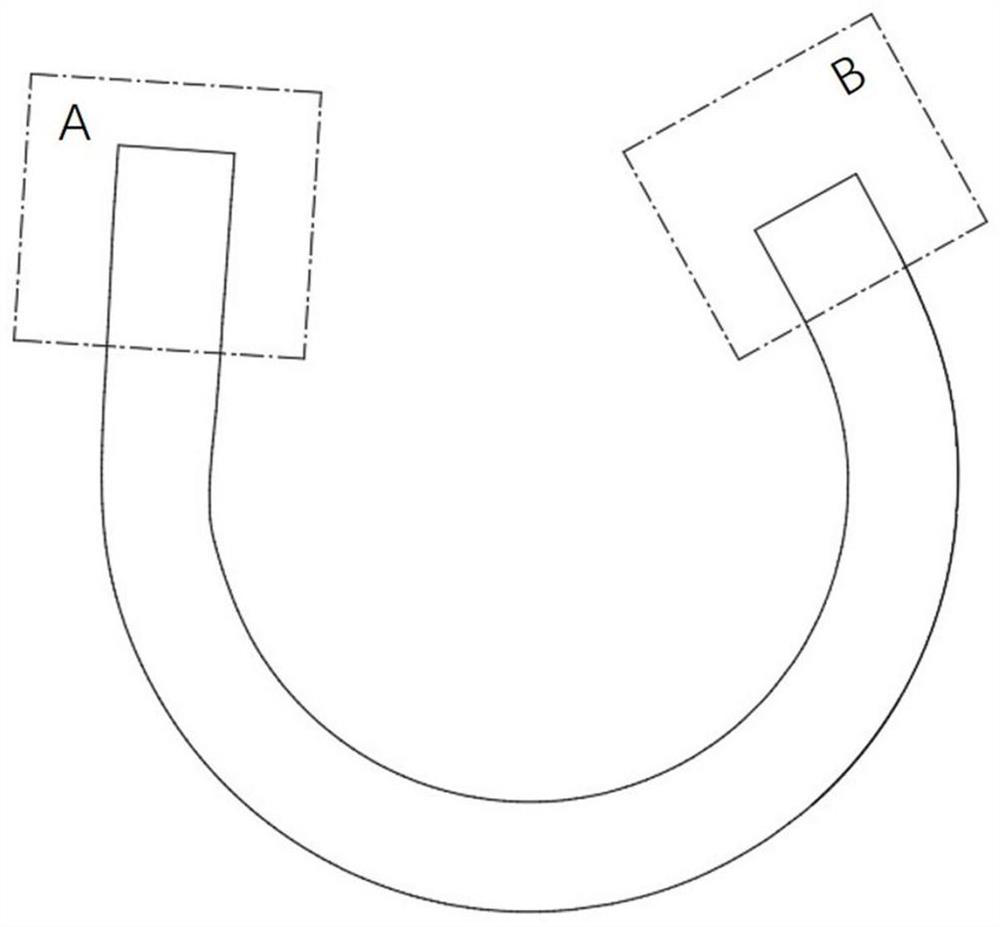

[0044] The curved pipe model is projected to obtain the contour line of the straight line segment A before the bending starting point and the straight line segment B after the bending cutoff, such as figure 1 shown.

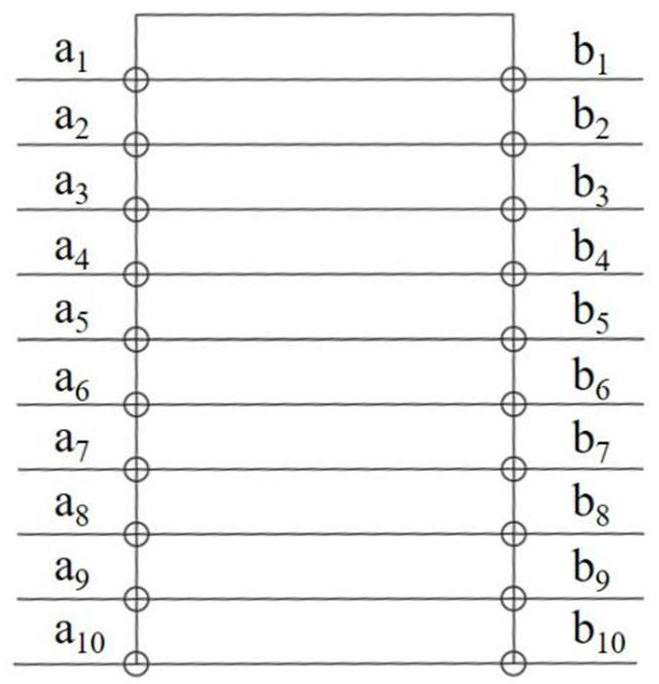

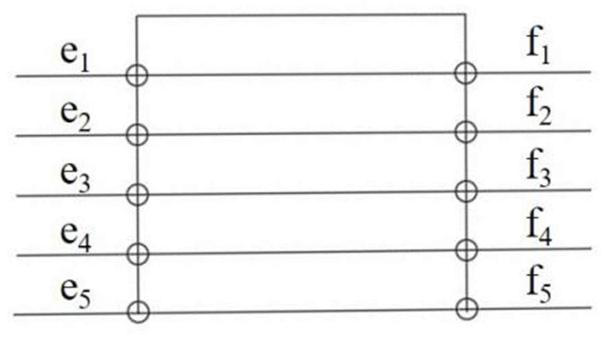

[0045] Step 2: Make an equidistant vertical line through the contour line, the vertical line is connected to the intersection point of the two contour lines, take the midpoints of all line segment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com