Operating force testing device and method and storage medium

A testing device, a technology for manipulating force, applied in measuring devices, force/torque/work measuring instruments, measuring forces applied to control elements, etc. Sexuality and authenticity, good overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

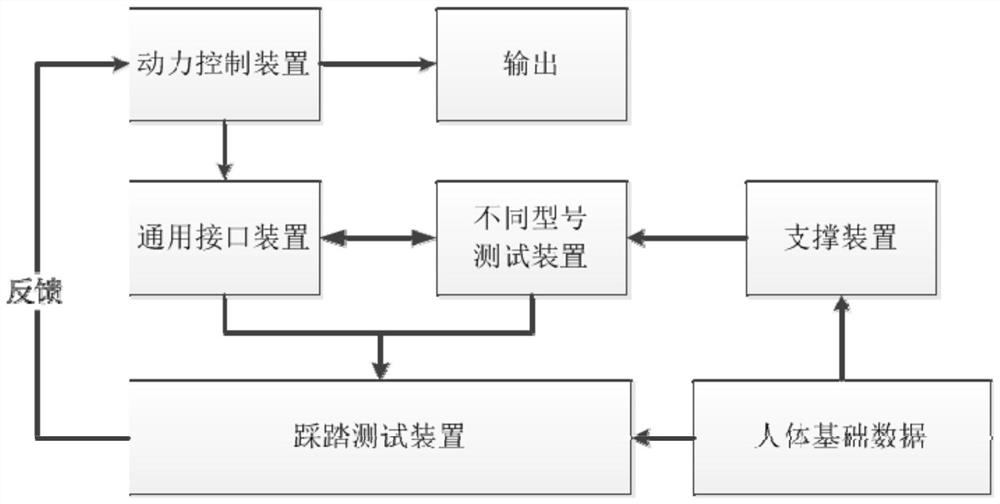

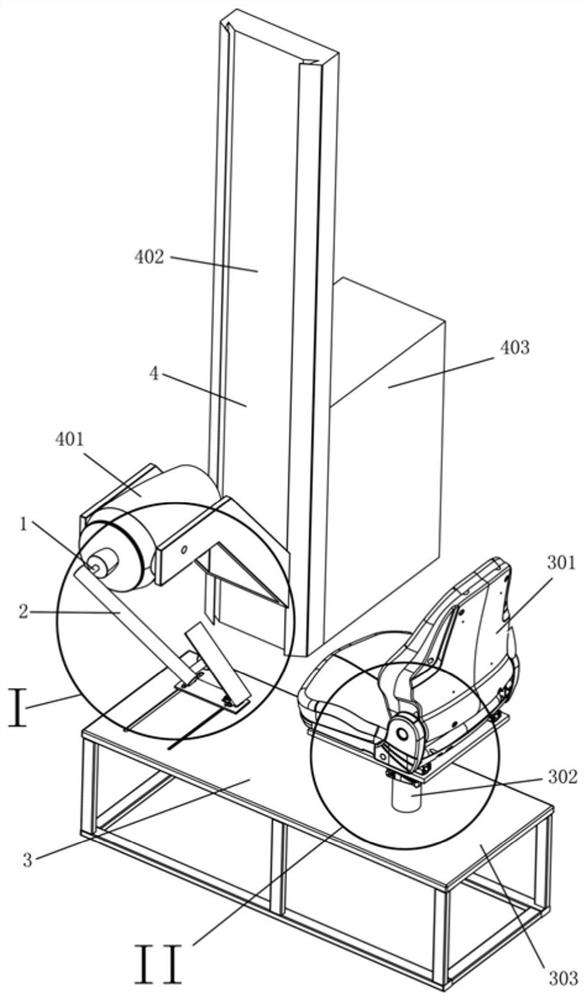

[0081] like Figure 1 to Figure 12 As shown, the test device of the present invention includes a universal interface device 1, a test assembly, a support device 3 and a power control device 4; one end of the universal interface device 1 is connected to the power control device 4, and the other end is connected to the test assembly by threads, and the support device 3 Set on the same side as the test assembly, the support device 3 is used as a test platform, and the power control device 4 is used to provide the manipulation force required for the test and record and output data during the test.

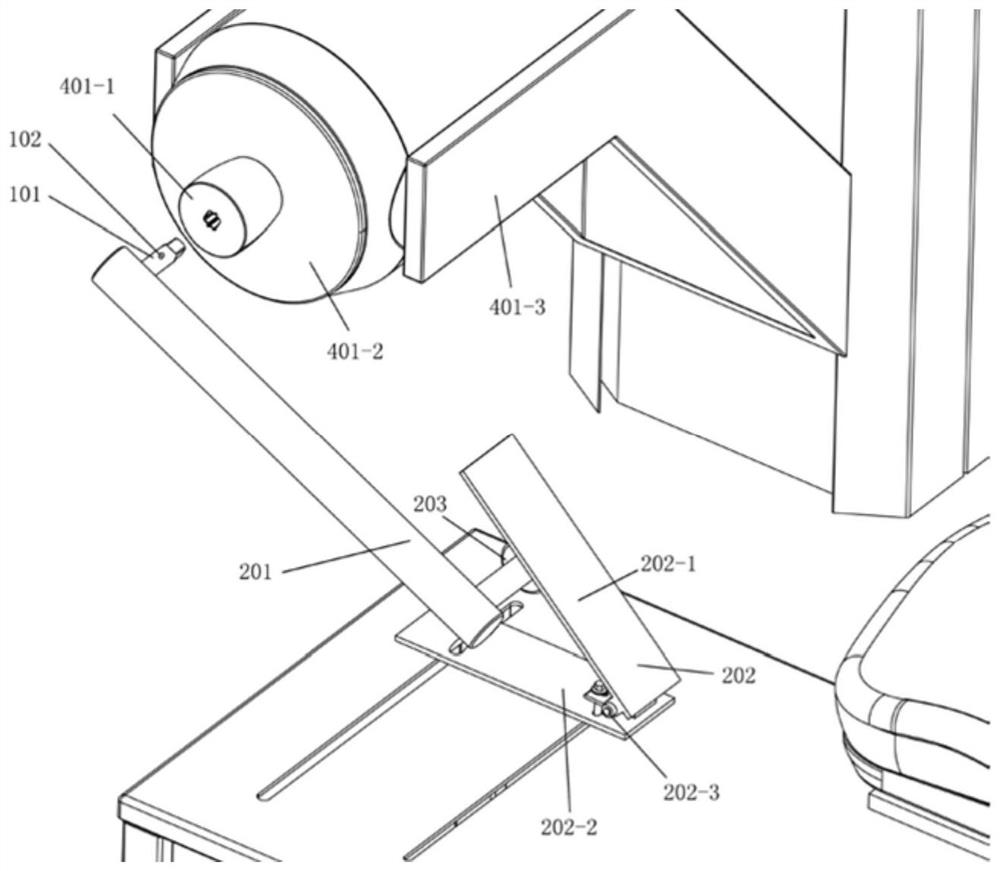

[0082] like image 3 , Figure 8-11 As shown, in a specific implementation of this embodiment, one end of the universal interface device 1 is sequentially provided with a joint piece 101 and a first pin shaft 102, the joint piece 101 is used to insert the power control device 4, and the first pin shaft 102 It is used to lock the connection between the joint 101 and the power control ...

Embodiment 2

[0117] The difference between embodiment 2 and embodiment 1 is that the test component is a handle test device.

[0118] In a specific implementation of this embodiment, the handle testing device includes a handle and a fastener, and the handle is threadedly connected to the threaded end of the universal interface device 1 and fixed by the fastener.

[0119] In a specific implementation of this embodiment, the parameter information of the handle testing device includes information such as handle size, placement position, inclination angle, manipulation direction, manipulation stroke, and manipulation force value.

Embodiment 3

[0121] The difference between embodiment 3 and embodiment 1 is that the test component is a steering wheel test device.

[0122] In a specific implementation of this embodiment, the steering wheel testing device includes a steering wheel and fasteners, and the steering wheel is screwed to the threaded end of the universal interface device 1 and fixed by the fasteners.

[0123] In a specific implementation of this embodiment, the parameter information of the steering wheel testing device includes information such as the size of the steering wheel, the placement position, the tilt angle, and the value of the steering force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com