Water hardness detector and detection method thereof

A technology of water hardness and detector, which is applied in the direction of testing water hardness, testing water, material inspection products, etc., and can solve the problems of high labor cost and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

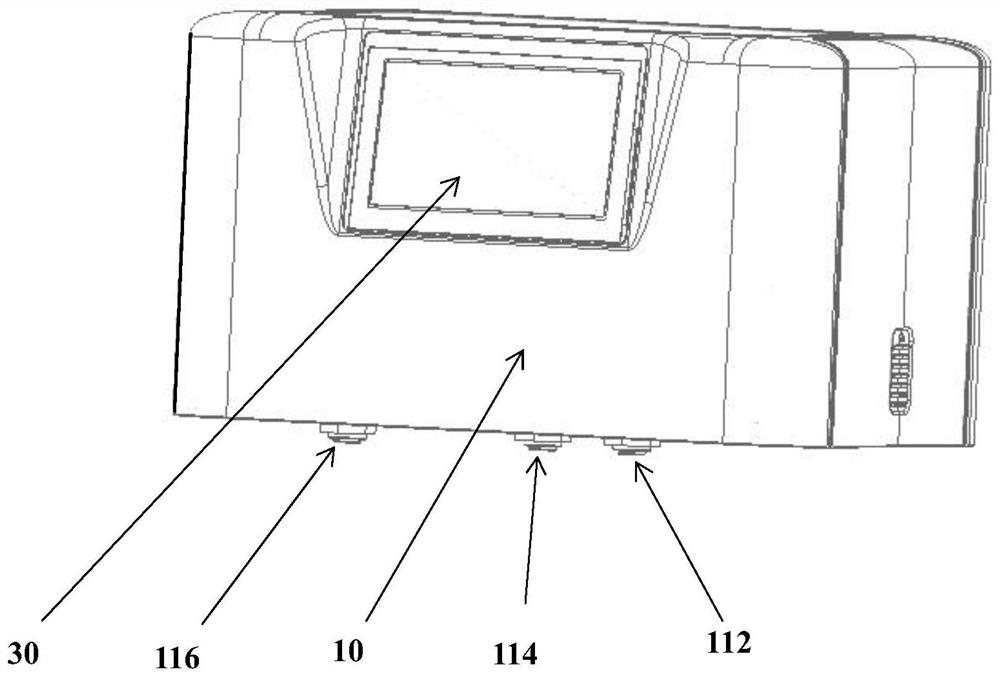

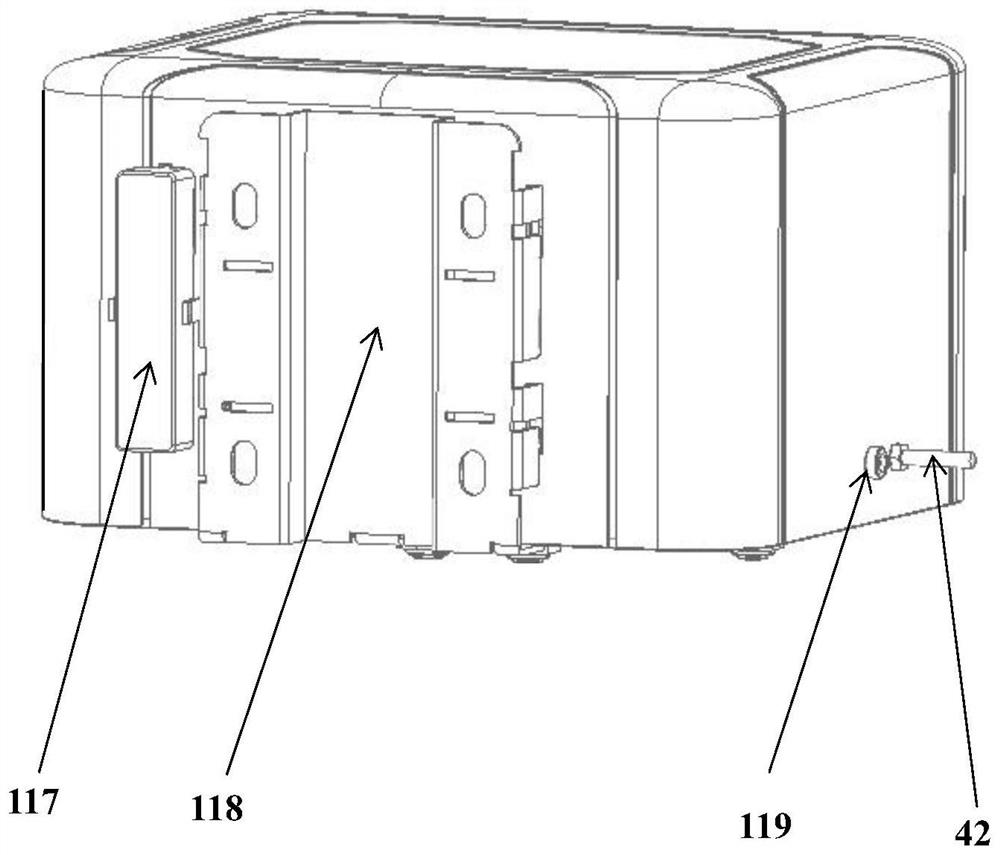

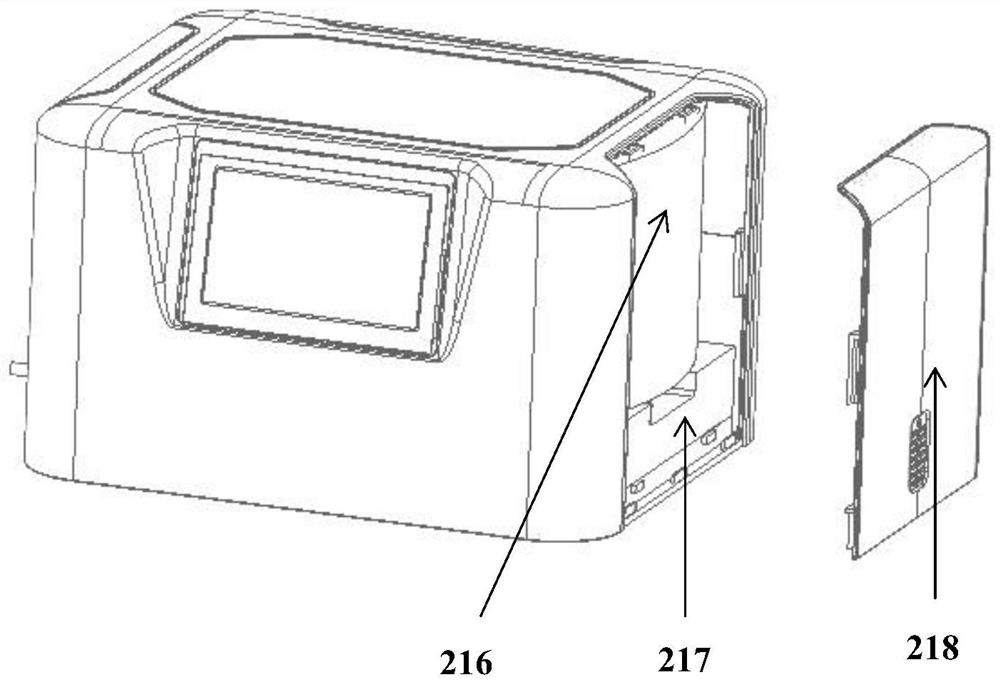

[0045] like figure 1As shown, the embodiment of the present invention provides a water hardness tester, which includes: a casing 10 and a water hardness detection device 20 disposed inside the casing 10 . Wherein, the structure of water hardness detection device 20 can refer to Figure 9 , specifically comprising: a water inlet module 220, connected to the detection container 210, for inputting the first volume of water to be tested into the detection container 210; a reagent input module 230, connected to the detection container 210, for inputting into the detection container 210 The reagent of the second volume; the detection container 210 is used to accommodate the mixed liquid formed by the first volume of water to be tested and the second volume of reagent; the water hardness detection module 250 is used to determine the color information of the mixed liquid according to the color information of the mixed liquid. The hardness value of the water.

[0046] In this embodim...

Embodiment 2

[0105] like Figure 10 As shown, the present embodiment provides a detection method of a water hardness detector, based on the water hardness detector described in Embodiment 1, the detection method includes:

[0106] S110: Control to input the first volume of water to be tested into the detection container 210;

[0107] S120: Control inputting a second volume of reagents into the detection container 210; the reagents may include calcium and magnesium ion detection reagents for detecting calcium and magnesium ions included in the water to be tested.

[0108] S130: Determine the hardness value of the water to be tested according to the color information of the mixed liquid formed by the water to be tested and the reagent.

[0109] In this embodiment, the color of the mixed liquid can be reflected to the color identification part by the reflective part opposite to the light emitting part for identification. According to the color information of the identified mixed liquid, suc...

Embodiment 3

[0111] like Figure 11 As shown, this embodiment provides a detection method of a water hardness tester, based on the water hardness tester described in Embodiment 1, the detection method mainly includes two parts: the process of entering the water to be tested and the process of draining the water to be tested. Among them, in the process of entering the water to be tested, the input of the water to be tested is divided into two ways. The first way is to perform a water discharge process through the water discharge valve structure to prevent residual water in the pipeline and ensure that the water to be tested entering the detection container 210 is pure. degree; the second way enters the detection container 210 through the water structure to be tested to perform the function of detecting water hardness.

[0112] In the process of draining the water to be tested, both the drain valve and the detection container 210 need to be drained from the drain port 116 and then drained in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com