Forward-tilting prevention device of high-plant crop divider

A technology for grain dividers and crops, which is applied in fields such as grain dividers, agricultural machinery and implements, and applications, and can solve problems such as missing cuts, unfavorable cutters, affecting cutting and laying effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

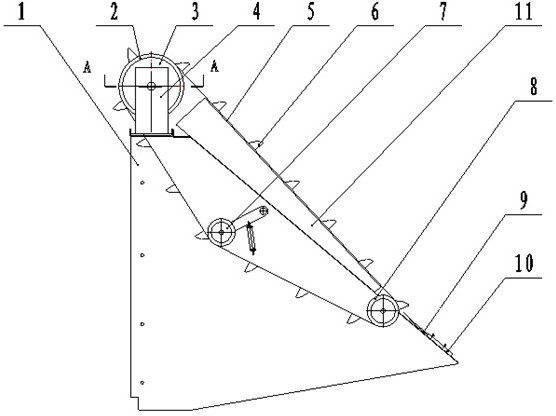

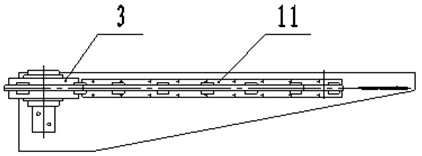

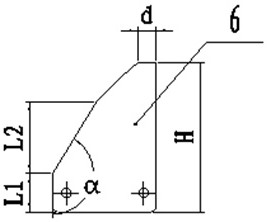

[0017] An anti-tilt device for a grain divider for high-plant crops, which is arranged on the upper end surface of the grain divider 1, and consists of a driving sprocket 2, a sprocket frame 4, a double-effect anti-winding cover 3, a hemp chain 5, and a hemp chain anti-twist. Wrap around guard plate 11, help hemp shifting tooth 6, tension wheel 7, driven sprocket 8, clearing hemp needle 9, clearing hemp needle fixed cover 10 and form.

[0018] Wherein, driving sprocket 2 is connected on the crossbeam near the grain divider 1 side at the front end of the frame by sprocket frame 4, and double-effect anti-winding cover 3 is symmetrically arranged on both sides of driving sprocket 2, and double-effect anti-winding cover 3 is fixed on On the bearing seat of the driving sprocket, cover the rotating part of the two sides of the driving sprocket 2 to prevent the hanging belt from being wound; the driven sprocket 8 is arranged on the upper end surface of the grain divider 1 near the tip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com