High-numerical-control forming equipment for steel and wood furniture and forming process

A technology for molding equipment and furniture, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of single desktop style and color, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

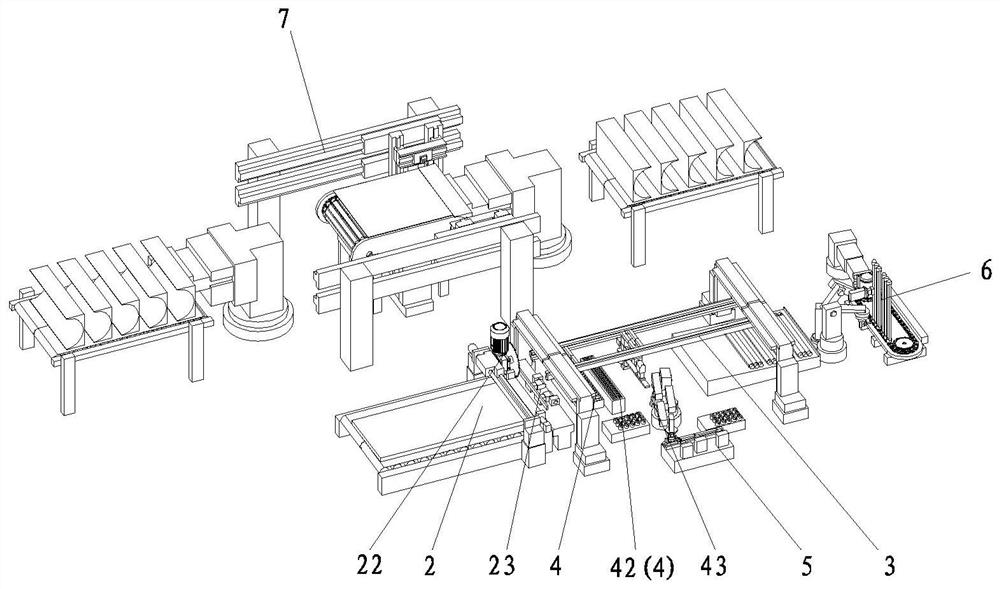

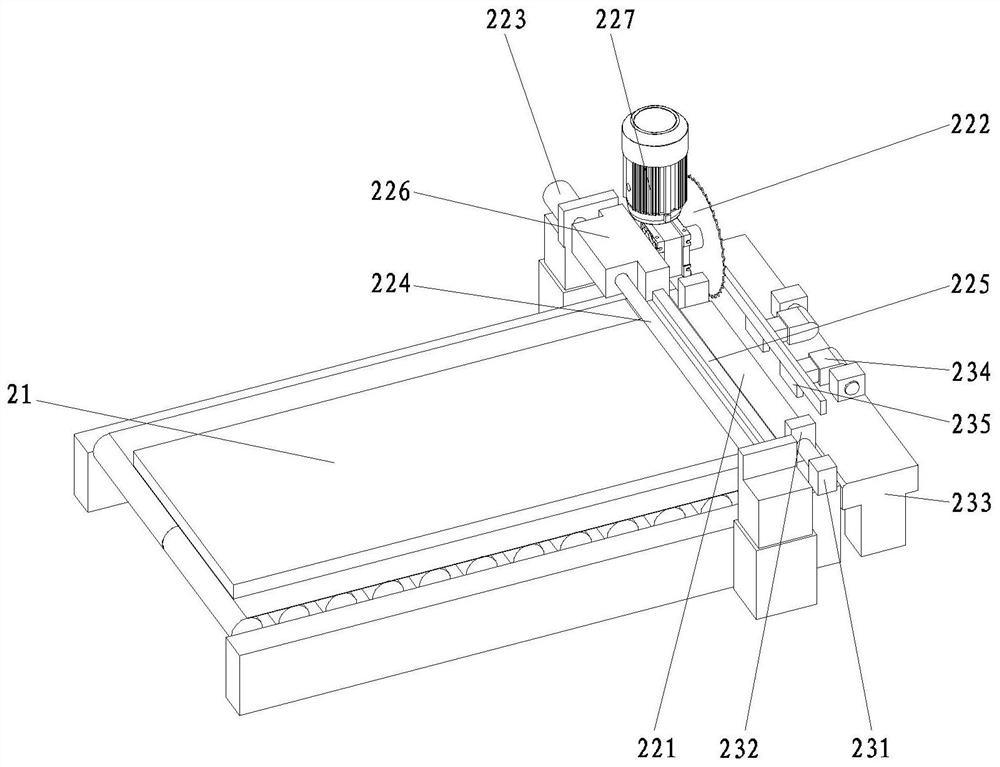

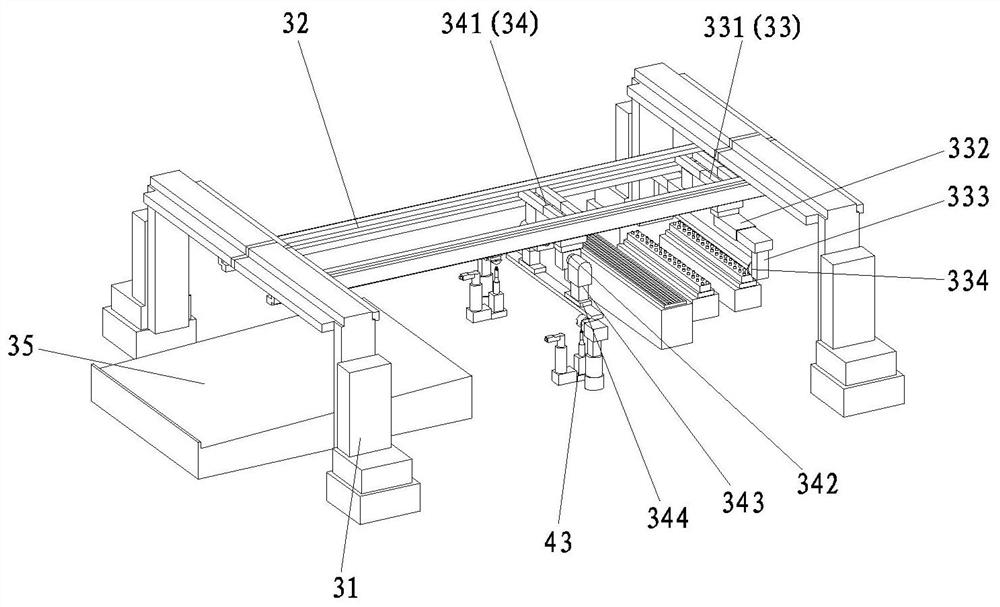

[0059] Such as Figure 1-8 As shown, a highly numerically controlled forming equipment for steel-wood furniture, which includes a cutting device 2 for uniformly cutting wood into planks 11, a plank conveying mechanism 3 for transporting planks 11, and a plank processing device for spraying and coloring planks 11 4. The drilling device 5 for drilling the connecting piece 12, the first welding device 6 for welding the connecting piece 12 of the plank 11 on the chain 14 and the second welding for welding the side plate 15, the cover plate 16 and the table foot 17 Device 7 ; the plank conveying mechanism 3 is arranged at the discharge end of the cutting device 2 , and the plank processing device 4 and the drilling device 5 are arranged below the plank conveying mechanism 3 .

[0060] After adopting the above struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com